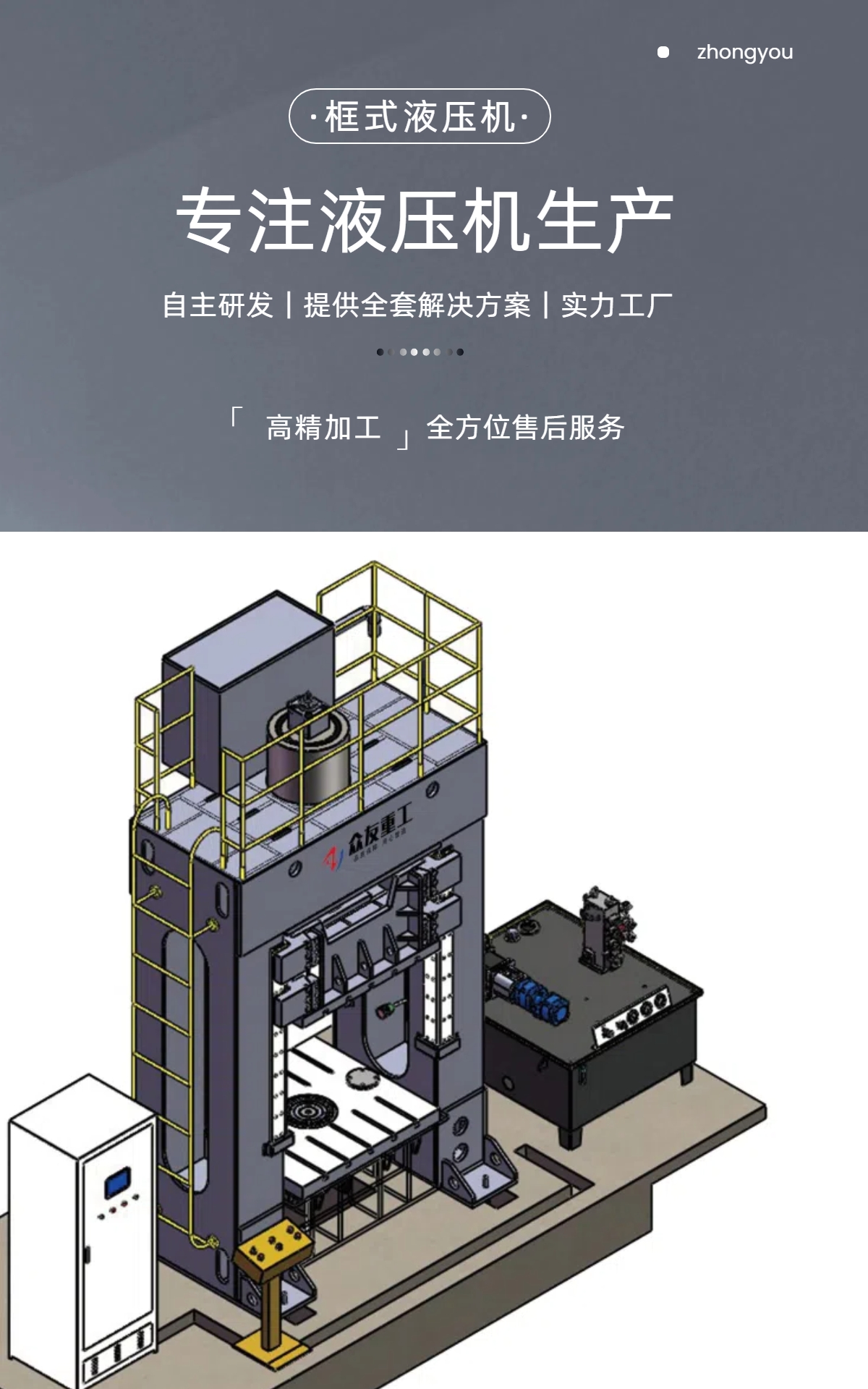

1000 tonsframe type hydraulic pressThe overall frame structure, the body strength is high, can withstand greater pressure and impact, to ensure the stability and reliability of the equipment in the working process, the four corners of the guide rail guide design, so that the machine has a good guide accuracy, anti-partial load capacity, to ensure the accuracy and quality of the workpiece in the processing process.

It has a variety of operation modes such as adjustment, manual operation and semi-automatic operation, and can be flexibly selected according to actual production requirements. It has two molding process specifications of fixed range and constant pressure. It adopts advanced hydraulic control system, reliable action, long service life, small hydraulic impact, reduced connecting pipelines and leakage points, improved work efficiency and safety, fast movement speed of slider, and can quickly complete the processing of workpieces, it can be used for various stamping processes such as stretching, blanking, bending, flanging, cold extrusion, etc. of metal materials. It is also suitable for correction, pressing, pressing molding of powder products and abrasive products, and pressing molding of plastic products and insulating materials.

The 1000-ton frame hydraulic press adopts rectangular rails with four corners and eight sides or X-shaped inclined rail guide rails, with adjustable clearance and good rigidity, which can effectively eliminate the influence of thermal expansion of the machine on the guide rail clearance.

The structure of the equipment is strong and durable, can withstand long-term high-load work, and ensure the stable operation of the production line. The fuselage is welded by high-strength steel plates. After tempering, vibration and aging treatment, the frame design is analyzed by limited elements to ensure small deformation of the machine. The main cylinder is made of high-quality carbon steel forgings, and the surface is quenched and chrome-plated to ensure long service life.

The slider is a steel plate welded box structure, and the bottom panel of the slider is a whole steel plate to ensure sufficient rigidity and strength. The slider is guided by four corners and eight sides to ensure high precision of motion guidance. It adopts integrated insertion system, which is sensitive, reliable and has good sealing performance. The hydraulic pump station is composed of oil tank, high pressure pump, motor, cartridge valve, cooler, filter, etc. to ensure the cleanliness of hydraulic oil and the stability of the system.

The 1000-ton frame hydraulic press adopts an integral welded frame bed, which has high strength and high compressive strength. It can withstand long-term high-load work without being deformed. The advantage of the frame structure is that it has good overall rigidity and can provide stable support. Ensure the stability and accuracy of the equipment under high pressure.

The frame and main components are made of high-quality steel, and undergo precise heat treatment and machining to ensure its mechanical performance and durability. The rectangular rails with four corners and eight sides can effectively eliminate the influence of the machine's thermal expansion on the guide rail gap and ensure high motion guidance accuracy.

The hydraulic system adopts integrated cartridge system, which is sensitive, reliable and has good sealing performance. The hydraulic pump station is composed of oil tank, high pressure pump, motor, cartridge valve, cooler, filter, etc., which can provide stable and reliable pressure output. This design allows the equipment to maintain an efficient and stable working state under high pressure.

The design focuses on modularity, which is convenient for the installation, debugging and maintenance of the equipment. The modular design enables the equipment to quickly locate and replace the faulty parts in case of failure.

The process flow of the 1000 ton frame hydraulic press varies according to the specific application scenarios and process requirements, and the general process flow is summarized as follows:

Blank preparation, according to the shape and size of the required forging parts, select the appropriate raw materials, and carry out pretreatment such as cutting and blanking to obtain the required blank, and heat the blank to the appropriate forging temperature range. The purpose of heating is to improve the metal The plasticity of the body reduces the deformation resistance to facilitate subsequent forging operations. The heating methods usually include oil furnace heating, electric heating, etc.

According to the requirements of the forging process, adjust the working parameters of the hydraulic press, such as pressure, stroke, speed, etc., and place the heated blank accurately in the cavity of the mold and position it to ensure the stability of the blank during the forging process.

Start the hydraulic press to make the slider go down, apply pressure to the blank, and perform the forging operation. During the forging process, control the stroke and pressure of the slider as needed to achieve the required forging deformation. During the forging process, pay close attention to the blank The deformation, the working state of the mold and the operating parameters of the hydraulic press.

When the forging operation is completed, stop the hydraulic press, make the slider move up, take out the forging from the mold, and follow-up treatment, cooling, cleaning, inspection, etc.

Zhongyou Heavy Industry strictly controls every production link, from the procurement of raw materials to the delivery of finished products, through strict quality inspection.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Customer satisfaction is our biggest motivation, we are committed to providing quality products and services to every customer.