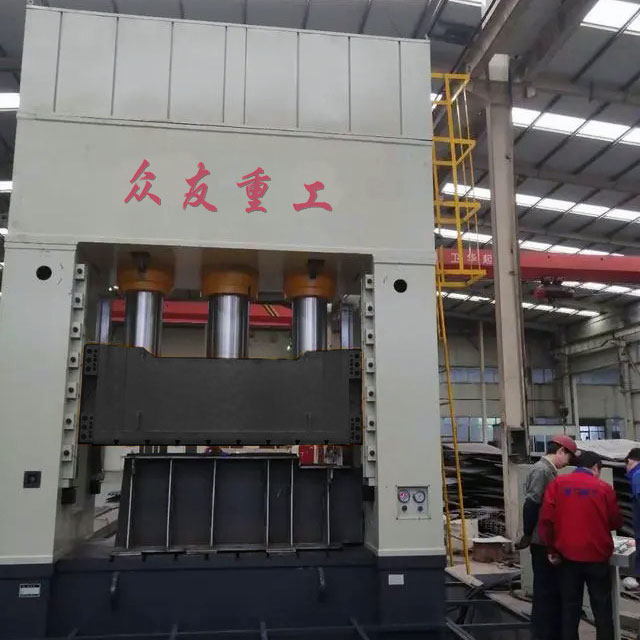

1200 tonsframe type hydraulic pressIt is widely used in many fields such as metal processing, plastic processing and hot forging processing. It is made of high-strength alloy steel to withstand the working load under high pressure.

The 1200-ton frame hydraulic press adopts a frame structure with high strength, high rigidity and high stability. The equipment is mainly composed of frame, hydraulic system, control system and workbench. The frame is made of high-strength steel and is formed by welding or casting to ensure that it can withstand great pressure without deformation. The workbench is the part of the hydraulic press that directly contacts the workpiece. The design needs to take into account the strength and precision. It is usually made of high-hardness materials and processed by precision to ensure the stability and accuracy of the workpiece during processing.

The working principle of the 1200-ton frame hydraulic press is based on Pascal's principle, that is, the pressure on the closed liquid can be transmitted to all directions unchanged. When the pressure of the hydraulic system reaches the set value, the piston will stop moving. At this time, the workpiece can be pressed, stretched and other processing operations. The hydraulic system is the core part of the hydraulic press, including oil pump, hydraulic cylinder, control valve, oil tank and other components, the driving hydraulic cylinder produces a huge thrust, which is transmitted to the worktable through the piston rod, and then acts on the workpiece.

1200-ton frame hydraulic press has a wide range of applications, in metal processing, plastic processing, hot forging processing, etc.; in the metal processing industry, it is mainly used for metal pressing and forming, and can handle thick steel plates, aluminum alloys and other materials. It is widely used in automobile manufacturing, shipbuilding, aerospace and other fields. In the field of hot forging processing, the 1200-ton frame hydraulic press also plays an important role for forging workpieces.

The 1200-ton frame hydraulic press has high strength and high rigidity, and can withstand huge pressure without deformation. The frame is usually made of high-strength steel and connected by precision welding or casting processes to form a stable whole. The worktable (also known as slider) is the part of the hydraulic press that directly contacts the workpiece. Its design needs to take into account strength and precision.

The guide rail system is very important for the accuracy and stability of the hydraulic press. The 1200-ton frame hydraulic press adopts high-precision four-angle and eight-sided guide rails with adjustable guide rail clearance and good rigidity, which can effectively eliminate the influence of machine thermal expansion on guide rail clearance and ensure high motion guidance accuracy.

The 1200-ton frame hydraulic press usually adopts a modular design, which is convenient for the installation, debugging and maintenance of the equipment. The various parts of the equipment are designed with a structure that is easy to disassemble and replace, making the maintenance of the equipment more convenient and quick.

The hydraulic press is equipped with advanced PLC (programmable logic controller) system, which can realize precise control of pressure, stroke and speed, and can also perform fault diagnosis and alarm.

The process flow of the 1200-ton frame hydraulic press varies depending on the application field, and can generally be summarized as the following main steps:

Preliminary preparation, confirm the safety of the working environment of the 1200-ton frame hydraulic press, and check whether the hydraulic system, electrical system and mechanical parts of the hydraulic press are operating normally. According to the processing requirements, select the appropriate mold and install it on the hydraulic press. Set the pressure, speed and other parameters in the control system of the hydraulic press.

Workpiece processing, the workpiece to be processed is placed on the worktable of the hydraulic press, and clamping and positioning are carried out to ensure that the workpiece will not move or deform during the processing; press the start button, the hydraulic system starts to work, during the processing, It is necessary to pay close attention to the working state of the hydraulic press; after the processing is completed, take out the workpiece and inspect the processed workpiece, including the inspection of size, shape, surface quality, etc.

Special process (taking hot forging as an example): it is divided into material heating, the purpose of heating is to improve the plasticity of the material and reduce the deformation resistance.

High-precision processing can meet various complex process requirements, realize precise pressure control and stroke adjustment, and ensure stable product quality

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

High efficiency production, fast action response and stable operation performance, for you to improve production efficiency and reduce costs