The four-angle eight-sided right-angle guide rail is adopted for guiding. This guide rail structure can ensure the accuracy and stability of the slider in the movement process, make the movement of the slider more stable and smooth, thus improving the processing accuracy of the equipment. The oil cylinder is one of the core components of the hydraulic press. The oil cylinder of the 1500-ton frame hydraulic press is generally made of forged steel. After precision processing and heat treatment, the surface of the piston rod is quenched with high hardness and wear resistance, it can ensure that there will be no problems such as wear and deformation during long-term use, and ensure the sealing and service life of the oil cylinder.

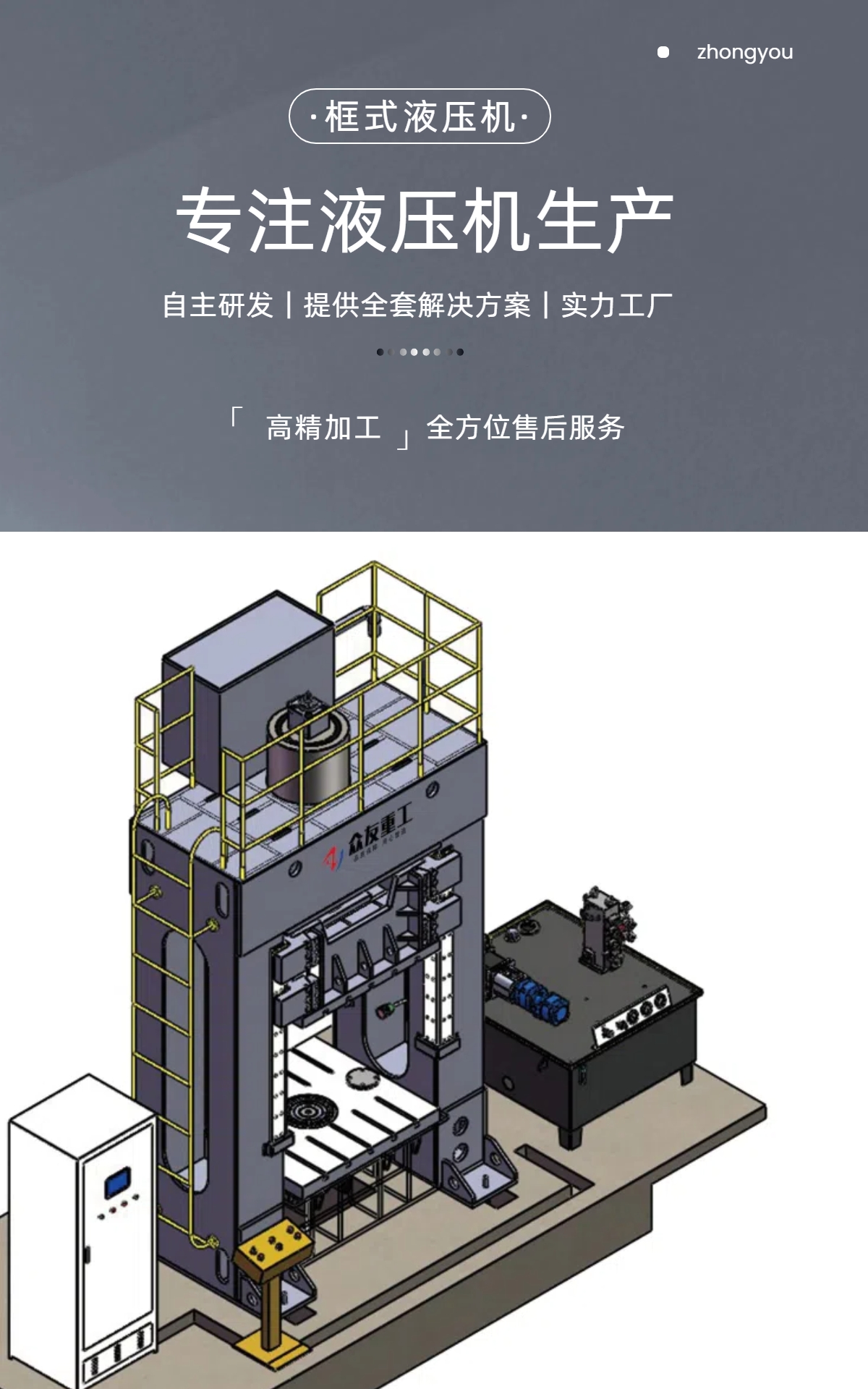

The structural design of the 1500-ton frame hydraulic press is conducive to production, the reasonable layout of the high-rigidity frame, the high precision of parts processing, the advanced production technology, and the accuracy.The overall performance of the equipment is guaranteed.

It has a wide range of applicability and can be used for stamping, forging, stretching, bending, forming and other processing technologies of metal materials. It can also be easily handled for the processing of various high-strength alloy sheets. It can also be used for stamping, shaping, overmolding and trimming of non-metallic materials, such as the processing of rubber, plastics, ceramics, powder metallurgy and other materials.

Using PLC and other advanced control system, can realize automatic control, easy to operate. The operator can easily complete the start, stop, adjustment and other operations of the equipment through the buttons or touch screen on the operation panel, and can monitor the operating status of the equipment in real time.

With manual, semi-automatic, automatic and other operating modes, it can meet the needs of different users. When debugging equipment or small batch production, you can choose manual operation mode; when mass production, you can choose semi-automatic or automatic operation mode to improve production efficiency.

The fuselage of the 1500-ton frame hydraulic press usually adopts an integral frame or a combined frame structure, which is welded by all steel plates. This structure has good rigidity and stability, and can withstand greater working pressure and impact. The four-angle eight-sided right-angle guide rails of the fuselage have high guiding accuracy and good rigidity, and adopt hydraulic pretension to ensure the stability and accuracy of the equipment in the working process.

The hydraulic system is the core part of the 1500-ton frame hydraulic press, which is mainly composed of oil tank, oil pump motor group, two-way cartridge valve and so on. The oil tank is a steel plate welding part, and the motor oil pump and the two-way cartridge valve group are placed on the upper part of the oil tank. The system has a centralized structure and is compact, which is convenient for inspection, adjustment and maintenance. The hydraulic system adopts cartridge valve integrated system, which is sensitive, reliable and has good sealing performance. The main pipeline is flanged, and the pipeline is provided with anti-vibration measures to ensure the stability and safety of the hydraulic system.

The power system usually adopts oil-immersed vertical pump group, which reduces noise, has good oil absorption effect and improves the service life of the hydraulic pump. At the same time, the power system can also be configured with multiple pumps according to work requirements to achieve more complex actions and higher stability.

According to the design requirements of the product, select the appropriate raw materials. These raw materials may include sheet metal, composite materials, etc. Ensure that the texture, thickness and size of the material meet the production requirements, and design and manufacture suitable molds according to the shape and size of the product. The quality and design of the mold directly affect the accuracy and surface quality of the molded product. Therefore, the mold design and manufacturing process requires precise control.

Install the 1500-ton frame hydraulic press on a solid foundation to ensure that the equipment is level and stable. Then the wiring of the electrical control part and the pipeline installation of the hydraulic part are carried out, and the designed mold is installed on the workbench of the hydraulic press to ensure that the mold is installed firmly and accurately.

Place the prepared raw materials on the workbench of the hydraulic press, fix them, start the hydraulic press, pressurize the hydraulic oil through the hydraulic pump, and push the piston rod to generate strong pressure. This pressure presses the raw material in the mold into the desired product shape and size. In the molding process, it is necessary to accurately control the pressure and speed of the hydraulic press to ensure the quality and accuracy of the product. When the product is formed, the mold temperature is gradually reduced to cool the material and take out the product.

Shandong Zhongyou selects high-quality raw materials and advanced processing technology to ensure the accuracy and stability of the equipment ~

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Equipment from design, material selection, processing, to assembly and commissioning, strict testing and inspection