2000 tonsframe type hydraulic pressis largeforging pressBed equipment, also known as 2000-ton frame hydraulic press and 2000-T frame press, is mainly used for stamping of automobile covering parts, stretching of automobile sheet metal parts, molding of glass fiber reinforced plastic products (SMC auto parts), hot pressing of composite materials, molding of resin plastic products, forging of large construction machinery parts, hot die forging of mine parts, etc.

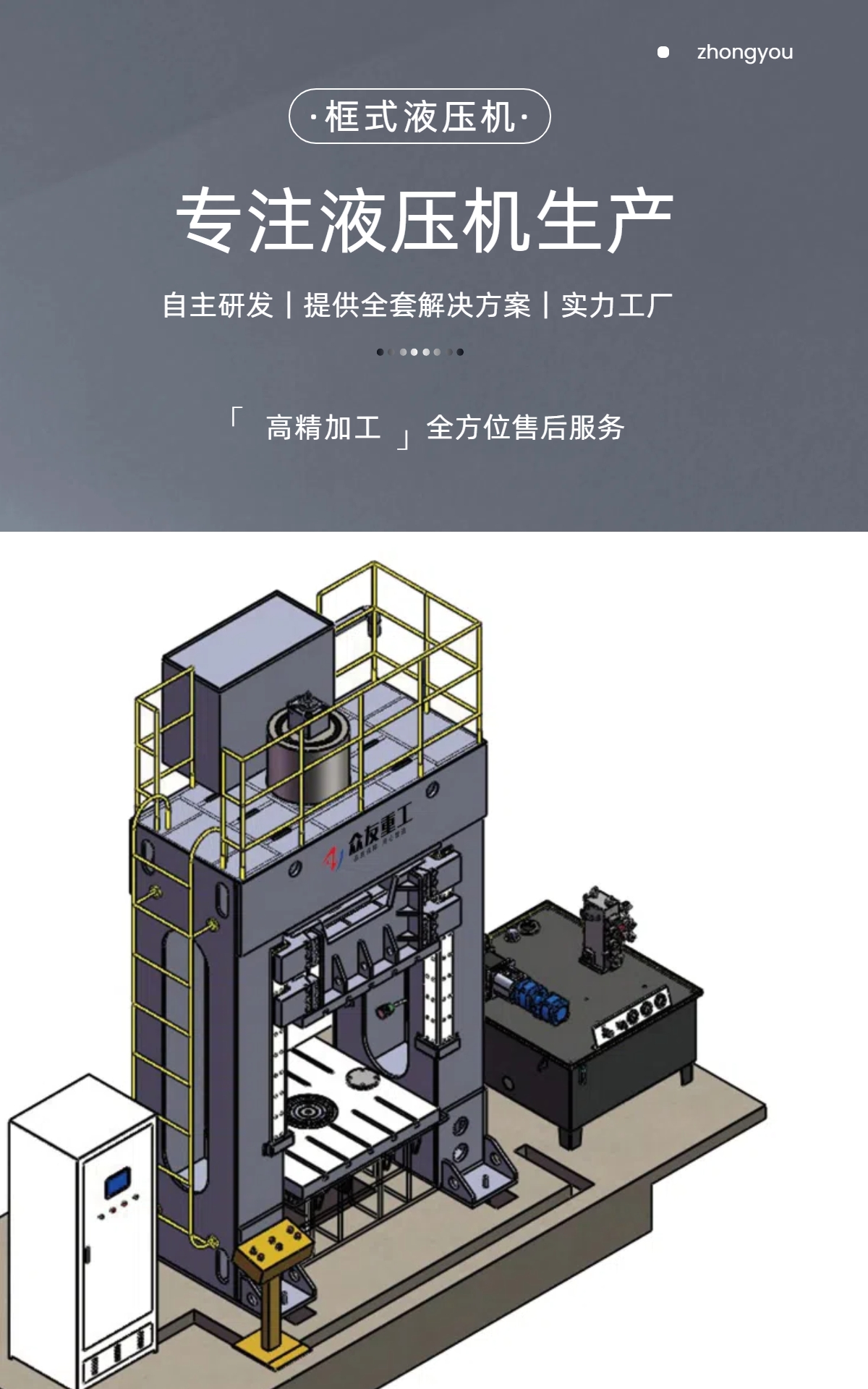

The frame structure adopts full steel plate welding, and has high rigidity and high precision after vibration aging treatment. The working slider is guided by four-sided guide rails, which has high adjustment working precision and strong anti-deflection load ability. The equipment is equipped with servo numerical control system and PLC touch screen, etc., which can realize automatic control and precise operation. It has hydraulic pad and anti-stretching function of upper slider and lower hydraulic pad.

The electrical system consists of a power circuit and a control circuit. The power circuit is 380V and 50HZ, which is responsible for the start, stop and protection of the oil pump motor. The core function of the control part is undertaken by the "PLC" programmable controller.

2000 ton hydraulic pressAccording to the process requirements, the instructions issued by the master control components (selection switches, buttons, etc.) and the signals measured by the detection components such as travel switches and pressure relays are used to process the switch quantity and analog quantity of the machine, drive the hydraulic pilot valve and other devices to realize the control of the pressure and displacement of the hydraulic actuator (oil cylinder), and then complete the production process of the machine.

The use of high-quality materials and advanced manufacturing technology, as well as precise guide rail guide system, can ensure the dimensional accuracy and surface quality of the processed parts; the overall frame structure has good rigidity and stability, and can effectively resist the vibration and impact of the equipment in the working process.

The automobile manufacturing industry can be used for stamping, forging, stretching and other processes of auto parts, such as the processing of frame, engine parts, body covering parts, etc., and the construction industry is used for the forming and processing of building materials, such as prefabricated components and bridges The manufacturing of bearings, etc., are widely used in the processing of hardware products, tableware, kitchenware, rubber, grinding wheels, ceramics, powder metallurgy and other industries.

The frame is welded with steel and subjected to tempering vibration aging treatment. The frame design has been analyzed by limited elements. It has the characteristics of high rigidity and high precision, and has strong anti-deformation ability, which can ensure that the machine maintains good stability during long-term use. And precision. The hydraulic cylinder is the core component that generates pressure. Its cylinder body is generally specially treated, such as rolling, tempering, etc. The surface of the piston rod is also hard chrome-plated and polished to improve wear resistance, corrosion resistance and surface finish.

The guide rail is guided by a four-angle eight-sided right-angle guide rail. This guide rail design makes the slider have high precision and good guidance when moving up and down, and has strong anti-deflection load ability, which can ensure that the equipment can still maintain stability when subjected to uneven load. Working state. The worktable can move up and down, which greatly expands the opening and closing height of the machine, and is convenient for operation and installation and disassembly of the workpiece. Some equipment can also be specially customized according to customer needs to move the worktable back and forth.

The hydraulic system includes hydraulic pump, hydraulic valve, hydraulic pipeline, hydraulic oil tank and other components. The hydraulic pump provides power for the system, and the hydraulic valve controls the flow direction, pressure and flow of the hydraulic oil to realize various actions of the equipment. The general use of electrical control system, can be divided into manual, semi-automatic and other modes of operation, some advanced equipment also uses servo motor control, with pressure and position of the closed-loop control function, to achieve digital control of all parameters, and has the mold parameter storage function and fault diagnosis function. The equipment is equipped with complete safety devices, such as two-hand buttons, safety light curtains, emergency stop buttons, etc. During the operation of the equipment, once an abnormal situation occurs, the safety devices can respond in time to stop the operation of the equipment.

According to the product's use conditions, mechanical properties, chemical composition, etc., select the appropriate metal materials, such as carbon structural steel, alloy structural steel or aluminum, copper and other metal plates, fine selection of the selected materials, de-oxidation, hammering and other treatment processes to improve the deformation capacity and continuity of the material.

According to the required product shape and size, select the appropriate mold and install it on the hydraulic press. According to the material characteristics and process requirements, set the pressure, speed, stroke and other parameters of the hydraulic press.

Place the pretreated material on the workbench of the hydraulic press and fix it, start the hydraulic press, pressurize the hydraulic oil through the hydraulic pump, and push the piston rod to generate strong pressure, so that the material is plastically deformed in the mold. The required shape and size, during the molding process, the hydraulic pressure is controlled according to the preset parameters.

For some products that need to improve the hardness and strength, cooling treatment is required after molding, and appearance inspection, hardness inspection, tensile test, etc. are carried out on the molded products to ensure that the product quality meets the relevant standards and requirements.

Zhongyou Heavy Industry will, as always, create greater value for customers with high-quality products, perfect services and reasonable prices.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

We have always been committed to providing customers with high-quality, high-performance hydraulic equipment.