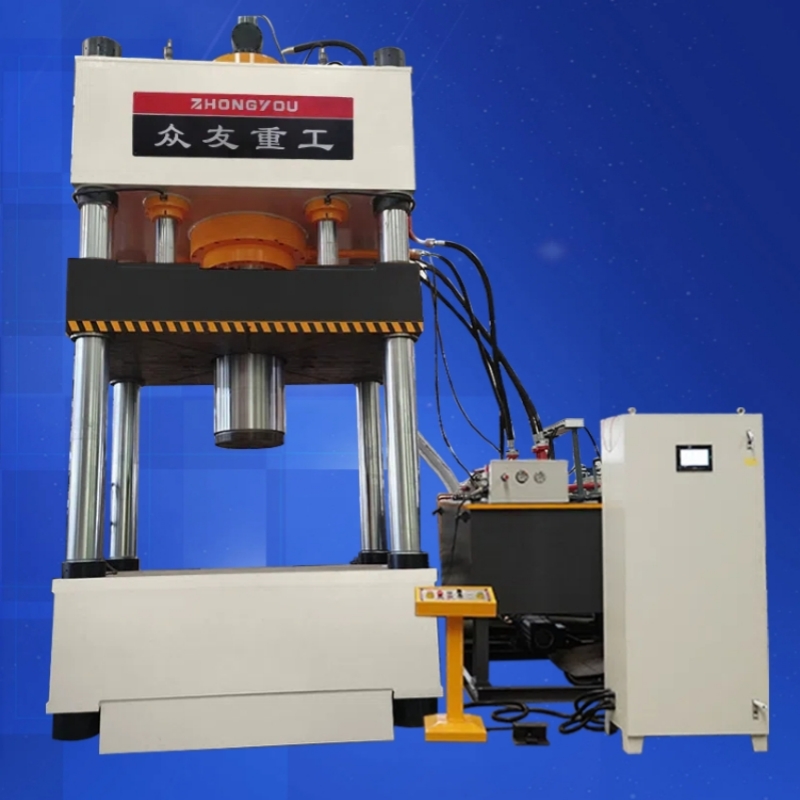

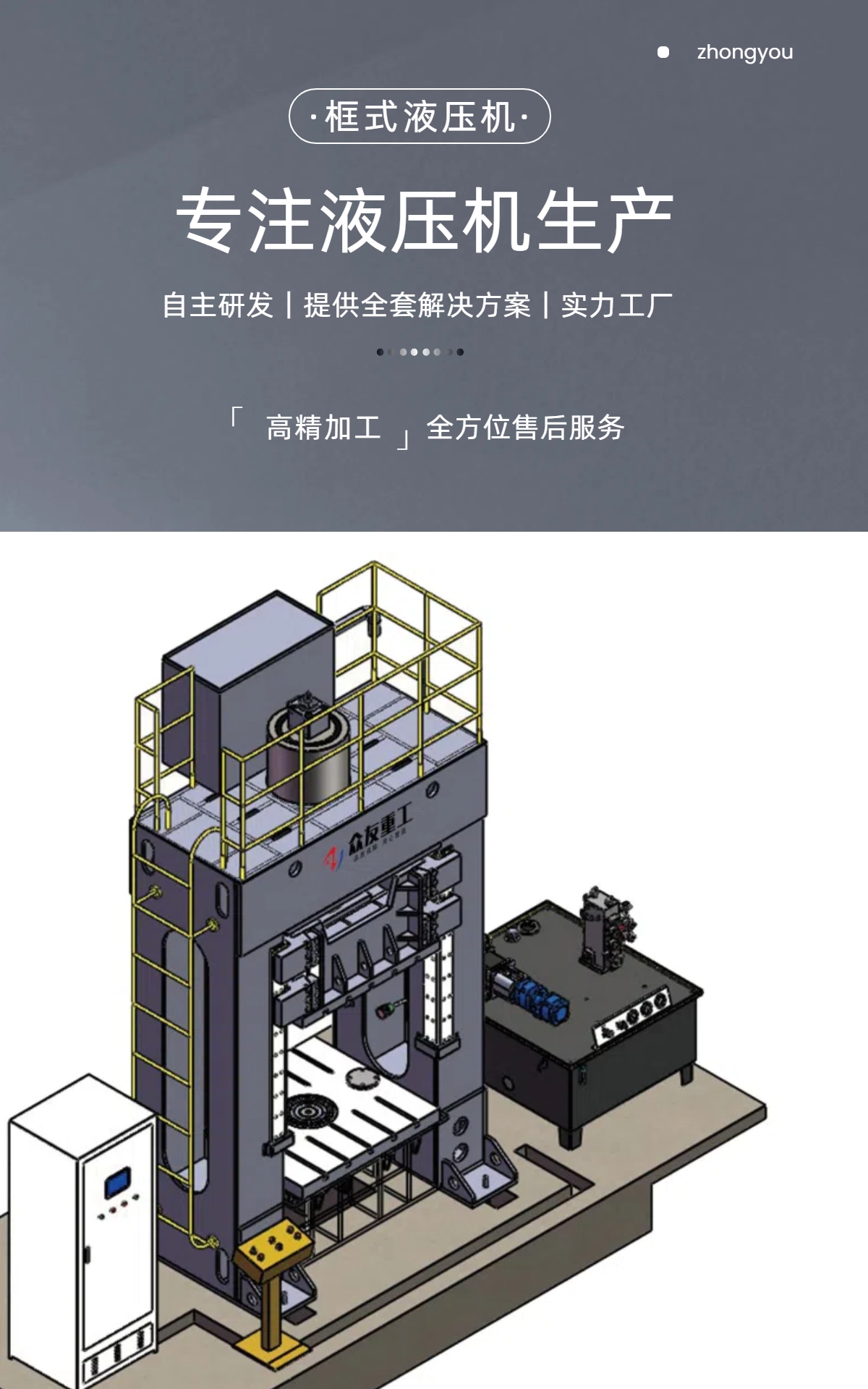

The 2000-ton hydraulic press is also called the 2000-ton hydraulic press and the 2000-ton press. Its body structure is diverse, and the most used is 2000-ton hydraulic press.four-column hydraulic pressand 2000 ton frame type hydraulic press. Among them, the 2000-ton four-column hydraulic press is divided into three beams and four columns, four beams and four columns, five beams and four columns and other structures. These hydraulic equipment required for the work table, opening, stroke, etc. can be customized according to process requirements design.

The 2000-ton hydraulic press is a general-purpose pressing equipment, which is suitable for the pressing process of plastic materials, such as powder product forming, plastic product forming, cold (hot) extrusion metal forming, sheet stretching, stamping, bending, flanging, correction, etc. Using advanced control system and hydraulic technology, it can realize high-precision positioning and pressing to ensure the quality of the workpiece. The hydraulic transmission system has the characteristics of fast response speed and low power loss, which makes the 2000-ton hydraulic press have high efficiency in the production process.

The 2000-ton hydraulic machine has a stable structure and can withstand large tonnage pressure without deformation or damage. It adopts button centralized control, has a variety of operation modes such as adjustment, manual and semi-automatic, and is widely used in various industrial fields, such as automobile manufacturing, aerospace, machinery manufacturing, metal processing, plastic products, powder metallurgy, etc.

After precision machining and optimized design, the equipment can ensure high precision when working. It has a variety of operation modes, rigid body structure and high-quality parts, which makes the hydraulic press have good stability in the working process. The forging industry can be used for the forging production of piston rods, bucket teeth, gears, auto parts, various special forgings, shafts, discs, and special-shaped parts, such as bearing inner ring, automobile casing, flange, half shaft, joint, crosshead, wheel hub, train wheel, etc., FRP fiber reinforced plastic/composite products such as thermosetting and thermoplastic DMC/SMC/BMC/GMT/LFT-D are molded. The metal powder compact industry directly presses various metal powder metallurgy, powder, alloy powder, stainless steel powder, ceramic powder, hard alloy, etc. into cylindrical blocks, auto parts manufacturing is suitable for the manufacture of large auto parts such as car doors and fenders. It has the characteristics of stable work, fast pressing speed and high production efficiency

2000 tons hydraulic press, the fuselage is generally composed of upper beam, lower beam, slider, column and nut. The upper and lower beams are firmly connected with four columns and nuts to form a rigid frame to ensure the stability of the equipment during work. Large parts are generally used large CNC floor boring and milling machine and high-precision CNC gantry milling machine for precision machining, and after computer optimization and finite element analysis, it has high strength and beautiful appearance.

The main cylinder mostly adopts a piston-cylinder structure, which is fixed in the center hole of the upper beam by bolts. The cylinder body is rolled, the piston rod is tempered, and the surface is polished with hard chrome plating, which has the characteristics of wear resistance, beauty and corrosion resistance.

Hydraulic system is the core part of the hydraulic machine, using two-way cartridge valve integrated system, can achieve precise control of pressure and flow. The system also includes a pump head control circuit, a master cylinder pressure circuit, a pressure setting circuit, etc., to meet the needs of different working statuses 3.

The process flow of the 2000-ton hydraulic press can vary according to its application field. The key steps are as follows:

Before operation, it is necessary to conduct a comprehensive inspection of the hydraulic press, including checking the integrity and normal function of the hydraulic system, electrical control system, mold and other components, and preparing an appropriate amount of raw materials according to production requirements.

In the powder molding process, the powder particles are evenly and quantitatively filled into the mold frame. For the molding process, such as the production of glass fiber reinforced plastic automobile deflector, the material needs to be added into the mold according to the specified amount, the hydraulic press is started, and the pressure molding is performed to compact the compact body or product. The size of the applied pressure, the pressing time, the pressing method and other factors need to be strictly controlled to ensure the quality of the product.

For the molding process requires timely exhaust operation, for materials that need to be cured, such as thermosetting plastics, need to be kept at the molding temperature for a period of time, so that the polycondensation reaction of the resin reaches the required degree of crosslinking.

After the article has achieved the desired shape and properties, a demolding operation is performed. This is usually done by means of an ejector rod or a special tool.

The 2000-ton hydraulic press has a stable structure and is easy to operate, with a wide range of applications and market needs.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products