There are many types of 315-ton hydraulic presses, such as four-column, gantry, single-column, etc., three-beamfour-column hydraulic pressThe most widely used, the three-beam and four-column structure is optimized by computer, which is simple, economical and applicable. Through the reasonable layout of the overall fuselage and columns, the stability of the equipment in the working process is guaranteed, and it can withstand greater working pressure and load., Provides the basis for high-precision processing.

315 ton hydraulic pressIt can be applied to powder molding, composite material molding, hot forging molding, metal extrusion, metal stretching, stamping anchor rod tray, hot pressing iron powder block, cattle and sheep licking brick block, fishing bait block, stainless steel product stretching, free forging hydraulic press and other applications.

The 315-ton four-column hydraulic press is composed of columns, upper and lower beams, sliders, and cylinders. The use of optimized hydraulic system and control system can improve the guidance accuracy and extend the service life of the equipment. According to different processing techniques, the hydraulic press has the functions of assembly, forming, correction, cutting, stamping and stretching.

315 tons hydraulic press, the type is a multi-functional hydraulic press, the common structure is three beams and four columns, which is widely used in the pressing, stretching, bending, flanging, cold extrusion, blanking and other processes of metal materials, and is also suitable for the pressing and forming of plastic products and powder products. The computer finite element analysis and optimization, to ensure that the equipment high strength, beautiful appearance and economical and practical.

The hydraulic press has a variety of operation modes, supporting manual, semi-automatic and automatic operation modes to meet different production requirements. It is equipped with PLC programming system to realize automatic control and improve work efficiency. It can realize two molding processes of constant pressure and constant process. It has pressure holding delay function. The working pressure, working speed and stroke range can be adjusted according to process requirements. The machine has high precision and the vertical precision of the movable plate is controlled by precision guide sleeve, to ensure the processing accuracy, accurate pressure positioning, can use a variety of positioning methods (such as oil cylinder adjustable mechanical positioning, position ruler electrical positioning, pressure sensor pressure positioning).

Four-column hydraulic press in metal forming, can be used for sheet stretching, bending, punching, hot pressing, bending and other processes;

In terms of powder molding, it can be used for the pressing of powder metallurgy parts, such as powder high-speed steel tools, molds, electrodes, etc;

In hot forging forming, it can be used for free forging, die forging, top forging, press extrusion and other processes, and can also be used to press sintered parts, molds and profiles of various materials;

In stretch forming, it can be used for cold drawing, cold blanking, fine blanking, flat finishing, press fitting and other processes, and can also be used for processing various ring parts, plates and profiles;

In terms of stamping, it can be used for stamping various plates and profiles, such as automobile bodies, railway vehicles, ships, motors, meters and other industries;

The 315-ton hydraulic press can be used for hot pressing, cold pressing, extrusion, shearing, straightening, shaping and other processes. It can also be used to process various ring parts, plates and profiles, etc.; it has different applications in different industries. It can be used for metal forming, powder forming, hot forging forming, metal extrusion, stretch forming, stamping forming and pressure processing.

The metal stamping forming process selects hot-rolled or cold-rolled steel plates, steel strips and other raw materials that meet the requirements. According to the product shape and size requirements, the corresponding stamping dies are installed and debugged to ensure the accuracy and stability of the dies., Start the hydraulic press to apply pressure to the raw material through the mold to plastically deform it to form a workpiece of the required shape and size. This process may include the application of various stamping processes such as blanking, bending, deep drawing, and bulging.

The process of hot-press molding of plastic products The process of hot-press molding of plastic products preheat the plastic material to shorten the molding time and dry the moisture in the material, then prepress the preheated material into a plastic blank of certain quality and shape, put the prepressed plastic blank into the mold of the hydraulic press, close the mold and heat and pressurize, so that the plastic melts and fills the cavity, and the hydraulic press provides stable pressure and temperature control, after the plastic is cooled and solidified in the mold, the mold is opened to take out the molded plastic products, and the products are cut, trimmed and other subsequent processing as required.

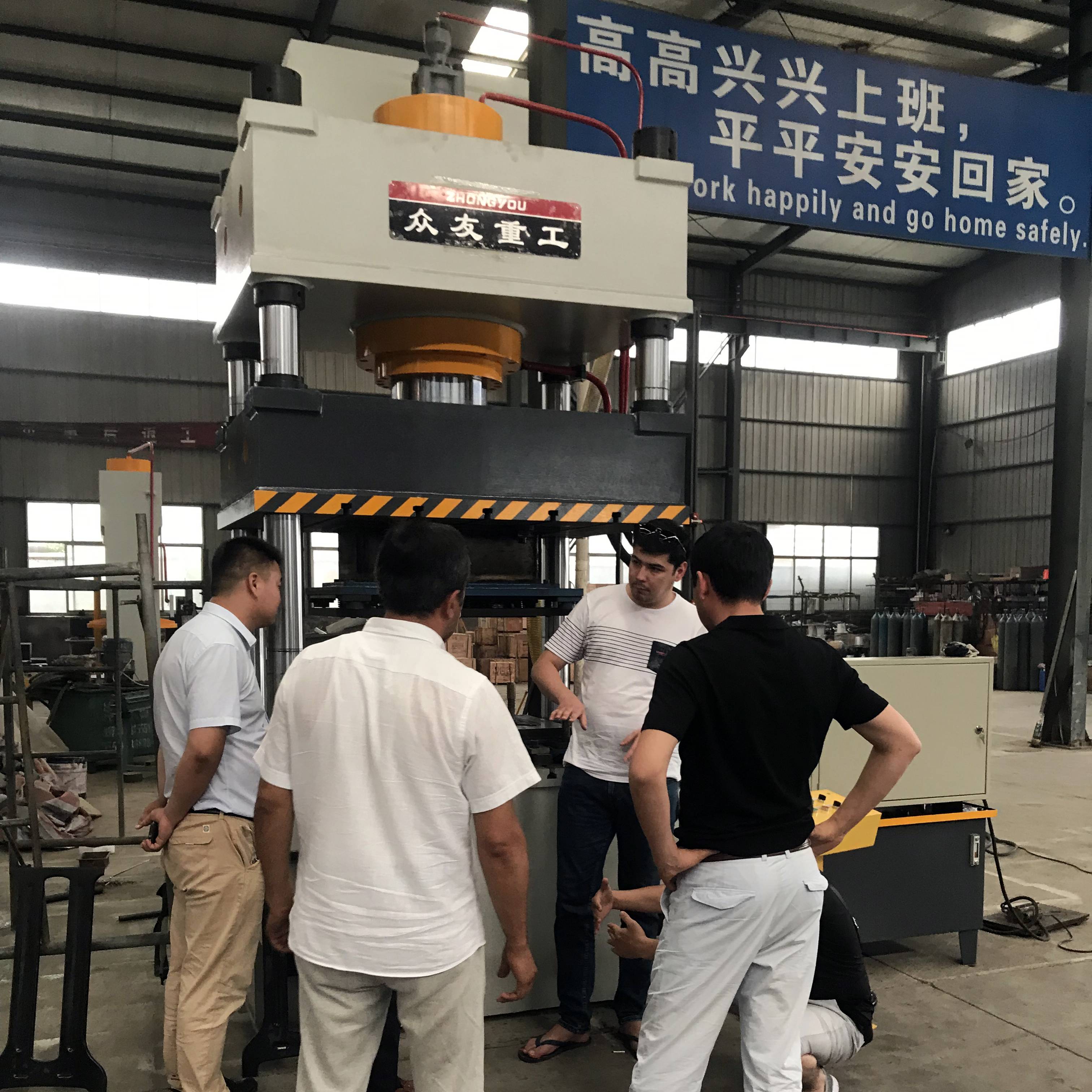

Shandong Zhongyou Heavy Industry is a company specializing in the research and development, production and service of large and medium-sized forging machine tool equipment.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Shandong Zhongyou Heavy Industry Hydraulic Press has strong performance advantages and a wide range of applications. Customers cover more than 300 cities across the country and overseas regions such as Central Asia, Europe, Africa, and South America.