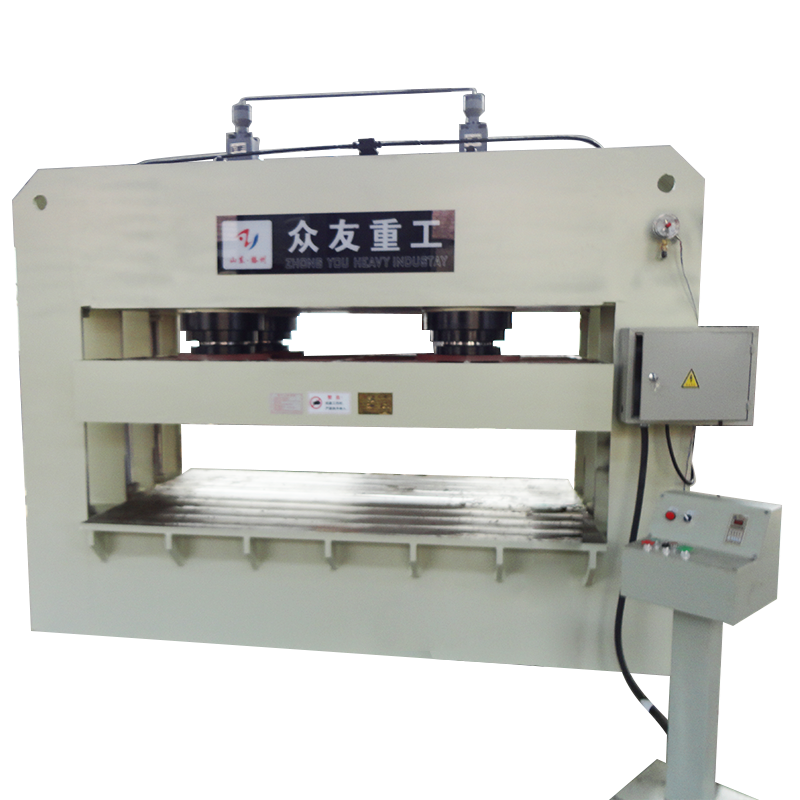

It is composed of the machine, power system and hydraulic control system, and adopts hydraulic transmission.

The whole frame or combined frame structure is adopted, the fuselage is welded with all steel plates, and the four corners and eight sides right-angle guide rail guide structure makes the pressing precision high and the rigidity good. The application of hydraulic pre-tightening technology of the press further enhances the stability of the equipment. The upper and lower beams of the equipment are integrally welded and formed with the column, eliminating the threaded connection of the traditional hydraulic press and avoiding the defect of loosening under long-term load. The column and other key components are made of high-strength materials, the bending resistance and fatigue resistance of the equipment are improved.

The hydraulic system adopts two-way plug-in integrated valve, which has stable work, reliable processing, long service life, less leakage and less failure points. The electrical system is controlled by numerical control PLC, which can be configured according to user requirements to add pressure, adjustable stroke, photoelectric protection device and mobile worktable.

The working principle of the 5000-ton frame hydraulic press is based on Pascal's law, and the pressure is amplified and transmitted through the transmission of hydraulic oil. In the working process, the hydraulic pump presses the hydraulic oil into the hydraulic cylinder and pushes the movable beam to move up and down, thereby pressing the workpiece. By adjusting the pressure and flow of the hydraulic system, the precise control of the pressing speed, pressing force and other parameters can be realized.

The overall frame structure makes the equipment have high rigidity and strong bearing capacity. The movement of the movable beam is guided by the plane adjustable guide device installed on the frame. The guiding accuracy is high. The high-strength materials and advanced welding technology are used to make the equipment. It can still maintain good performance during use and has strong fatigue resistance. The equipment adopts button centralized control, which is easy to operate and easy to operate and maintain.

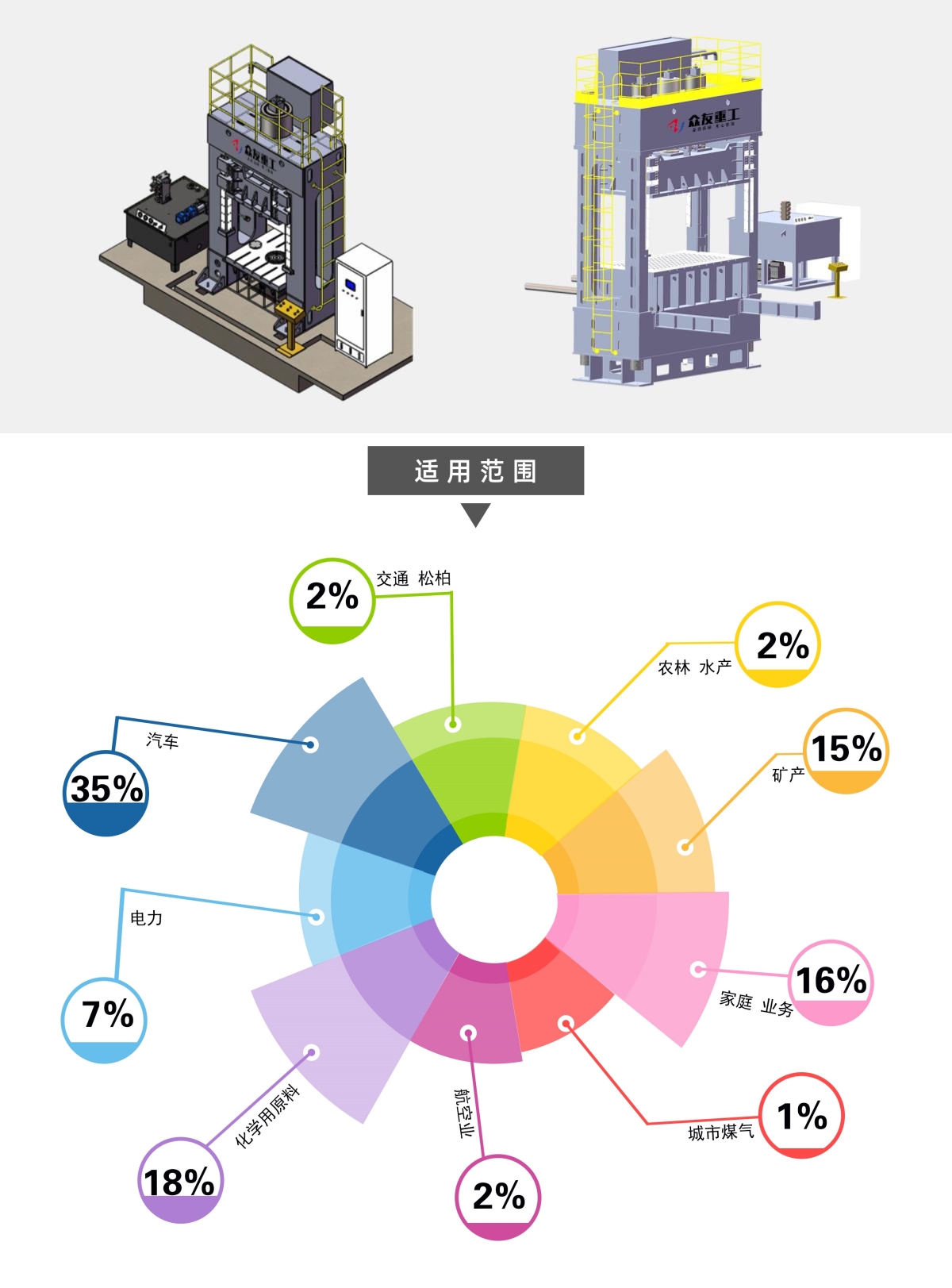

Widely used in metal processing, such as metal bending, stretching, flanging, extrusion forming, etc.; used for forging various metal parts, such as excavator bucket teeth, etc.; used for stamping automobile longitudinal and transverse beams, bridge corrugated steel webs, etc.

The 5000-ton frame hydraulic press adopts an integral frame or a combined frame structure. The body is welded with all steel plates. The four-angle eight-sided right-angle guide rail guide structure ensures high-precision and high-strength pressing capacity, and is suitable for large-scale and high-precision metal processing And forging tasks.

The upper and lower beams are directly welded with the column to avoid the loosening problem that may be caused by the threaded connection of the traditional hydraulic press. The column and other key components are made of high-strength materials, which improves the bending resistance and fatigue resistance of the equipment and can withstand long-term high Load work.

The hydraulic system is stable and reliable in processing. The electrical system adopts numerical control PLC control. It can be configured according to user requirements to add pressure, adjustable stroke, photoelectric protection device and mobile workbench, etc., which improves the automation degree and operation convenience of the equipment. The control system supports a variety of operation modes, such as inching, semi-automatic, automatic, etc., to meet different processing needs.

The pressing operation starts the hydraulic press, so that the movable beam moves downward under the push of the hydraulic cylinder. Under the action of the movable beam, the die presses the workpiece. According to the material, shape and size of the workpiece, adjust the pressure, speed and stroke parameters in the pressing process. Ensure that the workpiece is fully deformed and shaped during the pressing process. Holding and cooling: After the workpiece reaches the required shape and size, maintain a certain holding time to ensure that the stress inside the workpiece is released and stable. If necessary, the pressed workpiece is subjected to a cooling treatment to improve its hardness and strength. The cooling method may include natural cooling, air cooling or water cooling. Demoulding and cleaning: After the pressing is completed, the workpiece is released from the mold. Care was taken to maintain the integrity and surface finish of the workpiece. Clean up residues and impurities on equipment parts such as molds and workbenches to prepare for the next pressing operation.

Precision suppression, shaping extraordinary

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Every hydraulic press is our commitment to excellence!