5000 tons hydraulic press according to its fuselage structure, common 5000 tonsfour-column hydraulic press, 5000-ton frame hydraulic press, 5000-ton multi-cylinder multi-column hydraulic press, 5000-ton combined hydraulic press, etc. 5000-ton hydraulic press is widely used, such as 5000-tonHead stretching hydraulic press, 5000 tons of multi-directional forging hydraulic press, 5000 tons of metal powder hydraulic press are commonly used types. It is mainly used in the pressing process of metal materials, such as bending, flanging, extrusion, forming, correction, press-fitting, etc. It can also be used in the production of excavator forged bucket teeth, bulletproof armor plates, PE bulletproof insert plates, auto parts, train door container plates and other products.

Hydraulic presses work using the incompressibility of liquids and the nature of fluid transfer forces. The motor-driven oil pump sucks hydraulic oil from the oil tank and pressurizes it to the hydraulic cylinder. The hydraulic oil generates high pressure in the hydraulic cylinder and pushes the piston to move. The piston transmits the pressure to the working parts through contact with the working parts (such as molds, workpieces, etc.), so as to realize the processing, forming, stamping, bending, pressing and other processes of the workpiece. When the work is completed, the hydraulic oil returns to the oil tank through the hydraulic valve and waits for the next working cycle.

The common fuselage structure of 5000-ton hydraulic press includes four-column type, frame type, vertical and horizontal dual-use type, etc. The four-column hydraulic press is composed of three parts: the machine, the power system and the hydraulic control system. The fuselage is composed of an upper beam, a movable beam, a workbench and four columns, forming a closed rigid frame structure.

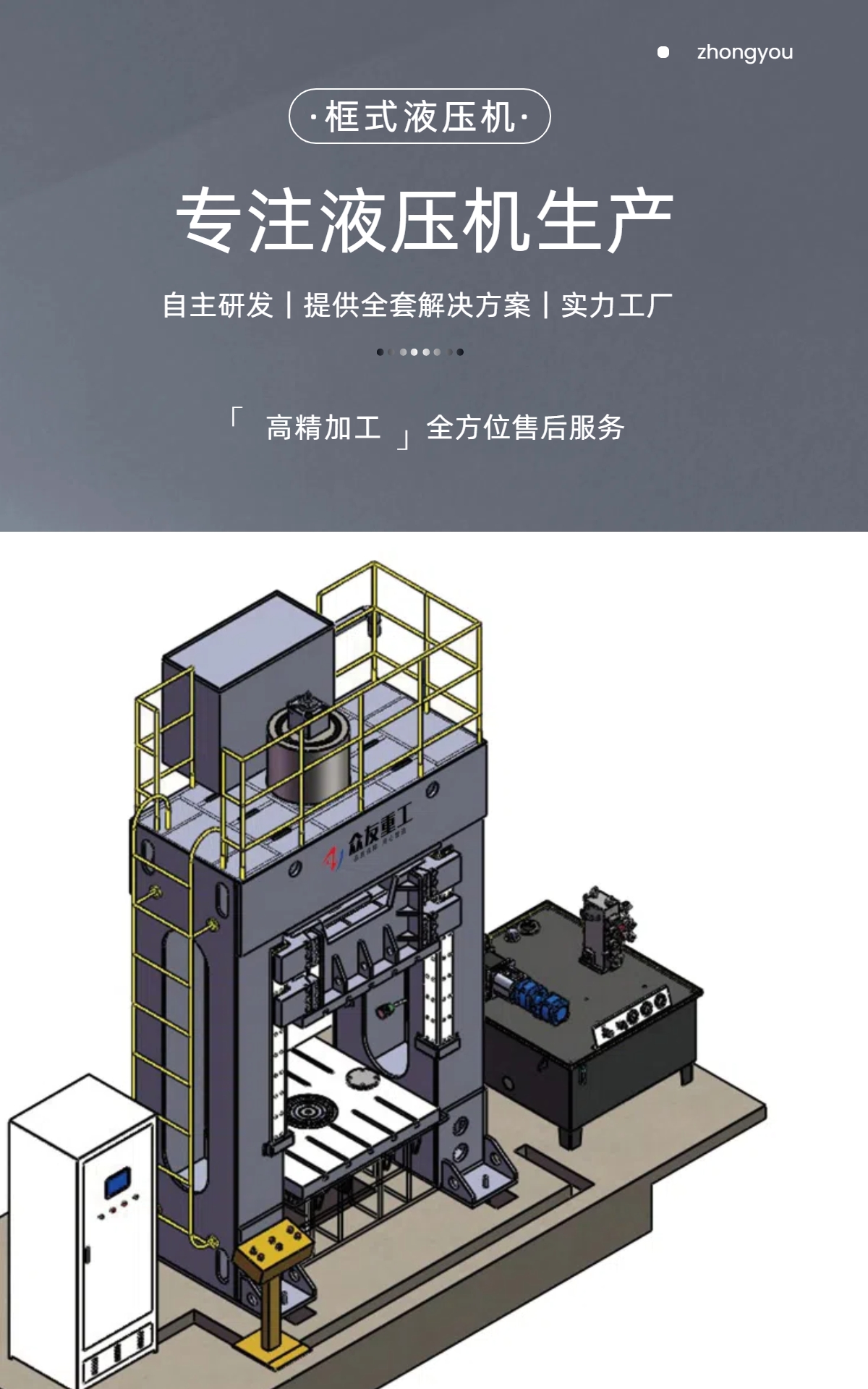

The frame type hydraulic press adopts the whole frame or the combination frame structure, which is welded with all steel plates. The four corners and eight sides right angle guide rail has high guiding precision and good rigidity.

The vertical and horizontal dual-purpose hydraulic press combines the characteristics of vertical hydraulic press and horizontal hydraulic press, and has higher flexibility and applicability. The working principle of the 5000-ton hydraulic press is based on Pascal's law, that is, the pressure on the closed liquid can be transmitted in all directions with the same size. When an external force is applied in a closed container, the force is uniformly transmitted by the liquid to all parts of the container. The hydraulic press uses this principle to convert mechanical energy into liquid pressure energy through a hydraulic pump, and then convert the liquid pressure energy into mechanical energy through a hydraulic cylinder, so as to realize the transmission and amplification of power.

The four-column fuselage is a three-beam and four-column vertical structure, which is composed of upper beam, slider, workbench, column, pipe hoop, guide column, etc. The upper beam, the slider and the worktable are usually forged by integral cast steel, which has good rigidity and strength, and the column plays a supporting and guiding role.

The frame type adopts the frame type rack welded by the whole steel plate, which has good overall rigidity and high compressive strength. The upper and lower beams and columns are directly welded together, eliminating the need for traditional threaded connections and avoiding the shortcomings of nuts loosening under long-term load. The frame structure deforms little when it bears the working load. When the movable beam is subjected to eccentric load, the lateral thrust is supported by the column, and the tie rod is not bent.

The multi-cylinder and multi-column fuselage adopts a three-beam, multi-column and multi-nut structure. The main components are steel plate welded structure, and the internal stress is eliminated by tempering after welding. The slider adopts multi-column guidance, which provides good guidance for the slider through the column to ensure the accuracy and stability of the movement.

The main process of the 5000-ton hydraulic press includes the preparation of raw materials. The parts of the hydraulic press mainly include the frame, oil cylinder, hydraulic pump, etc. These raw materials must undergo strict inspection and testing.

In the process of manufacturing, the various parts of the hydraulic press need to be fine processing and heat treatment, processing technology including turning, milling, grinding, forging and so on. In the process of processing, it is necessary to strictly control the processing technology and technology,. It is also necessary to carry out non-destructive testing of key components, such as ultrasonic testing, magnetic particle testing, etc., to find potential defects and deal with them in time.

In the assembly and debugging process, the overall structure of the hydraulic press is assembled according to the design requirements. In the assembly process, strict alignment, centering and angle detection are required,. After the assembly is completed, test run and debug the hydraulic press, including no-load operation, load operation and continuous operation, to ensure its normal operation and meet the design requirements.

Quality inspection is the last step of the entire production process. Only through quality inspection can the hydraulic press be put into use.

Our products cover four-column hydraulic press, frame hydraulic press, gantry hydraulic press, single arm hydraulic press and other types.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

We have established a perfect after-sales service system to provide customers with a full range of after-sales service. Including equipment installation and commissioning, technical training, maintenance, spare parts supply, etc., to ensure that customers have no worries in the process of using our hydraulic press.