Fan housingforming hydraulic pressCommon tonnages are 630T, 800T, 1000T, 1200T, 1500T, etc. The conventional size of the worktable is 800mm × 800mm, which is suitable for processing small fan shells. Medium 1200mm × 1500mm, meeting the requirements of conventional sizes; Large 2000mm × 3000mm and above can be used for the production of large industrial fan shells.

The opening height is typically between 800-2000mm. The larger opening height is convenient for the installation and disassembly of the mold and the taking and placing of large workpieces. The stroke range varies from 500mm-1500mm. The smaller stroke is suitable for the shallow shell type fan shell, while the larger stroke can meet the molding requirements of the deep cavity complex structure.

The precise hydraulic control system and guiding device can ensure that the dimensional tolerance of the fan housing is controlled within the range of ± 0.5 - ± 1mm, so that the housing and the internal fan components are perfectly matched.

The uniform pressure of the hydraulic press makes the FRP material evenly distributed in the mold, and the surface of the fan shell is smooth, free of bubbles and wrinkles, which improves the aesthetics and durability of the product.

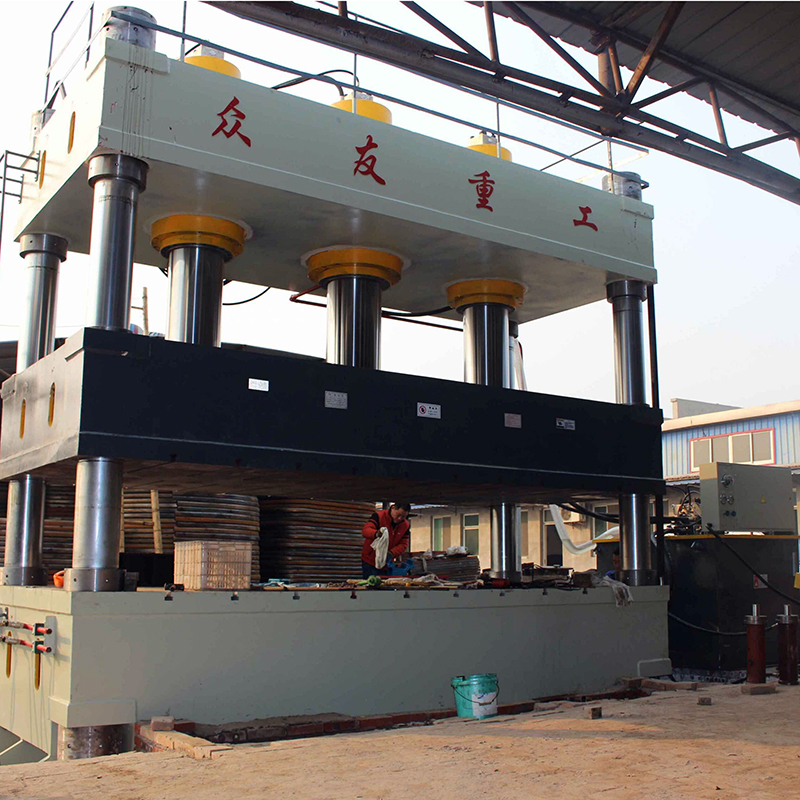

The uniform pressure of the hydraulic press makes the FRP material evenly distributed in the mold. The surface of the fan shell after molding is smooth, free of bubbles and wrinkles, which improves the aesthetics and durability of the product. Due to the uniform and sufficient pressure during the molding process, the FRP The fibers of the material are fully impregnated and compacted, thereby improving the overall strength of the fan shell and being able to withstand various stresses during fan operation. The four-column structure is stable and the guiding precision is high. It is suitable for high-precision forming of small and medium-sized fan shells, especially for fans with ventilation systems that require high dimensional accuracy. The frame structure has strong rigidity and large carrying capacity, and is suitable for large and heavy fan shells. Production, such as industrial large fans, cooling tower fans, etc.

In the field of industrial ventilation, it is used to manufacture fan shells for various industrial plants to ensure the ventilation effect while improving the reliability of the equipment; in the manufacture of air-conditioning equipment, it produces shells for the fans of outdoor and indoor units of air-conditioning equipment to meet different environments and Power air-conditioning equipment needs; in the field of cooling towers, special fan shells for cooling towers are manufactured to ensure the efficient operation and long-term stability of cooling towers.

The fuselage is made of high-strength steel plate welding or steel casting, such as Q345 steel. After tempering or vibration aging treatment, internal stress is eliminated to ensure that the fuselage does not deform under long-term high-load operation. The hydraulic cylinder tube is made of high-quality alloy steel pipe. For example, the inner wall of No.45 steel is chrome-plated after quenching and tempering treatment to improve wear resistance. The piston is made of high-strength aluminum alloy or alloy steel to ensure the sealing and reliability of the hydraulic cylinder. The mold is made of high-strength and high-hardness die steel, such as Cr12MoV steel. After quenching, tempering and other heat treatment processes, the hardness of the mold reaches the HRC55-60, ensuring that the mold does not deform or wear during frequent pressing.

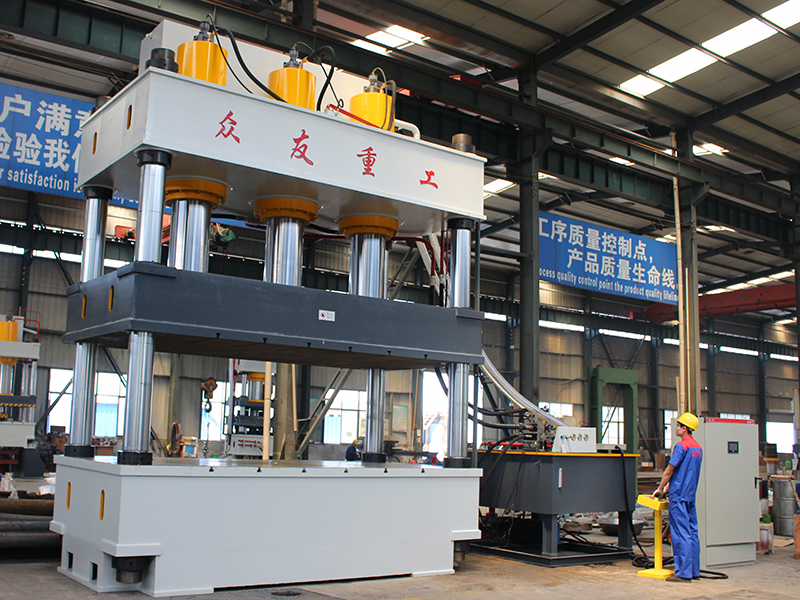

We provide customers with comprehensive equipment operation and maintenance training services. Customers are welcome to visit the manufacturer for on-site inspections. Customers can visit the production workshop to understand the production process of the fan shell forming hydraulic press, and can have face-to-face communication with production technicians to gain in-depth understanding The performance, characteristics and advantages of the equipment.

The hydraulic press process of fan shell molding usually covers many links from raw material preparation, mold design and manufacturing, equipment debugging, pressing molding, post-processing and quality inspection.

According to the design requirements of the fan shell, select the appropriate FRP (fiber reinforced plastic) materials, including resin, reinforced fibers (such as glass fiber, carbon fiber, etc.) and possible fillers and additives; surface treatment of reinforced fibers to improve its adhesion with the resin; to ensure that the resin is in a suitable temperature and viscosity state, easy to mix and pour.

In the process of pressing molding, first, the pre-prepared FRP material, including a mixture of resin and reinforcing fibers, is laid in the mold, the hydraulic press is started, the mold is closed, and a certain pressure and time are maintained for pressure curing to ensure that the FRP shell Strength and stability.

After the fan shell is cured, open the mold and take out the finished product. The removed FRP shell is trimmed and polished as necessary to remove burrs and uneven parts, and perform post-processing operations such as drilling and cutting.

The precision servo control system is adopted to ensure that the position accuracy of the mold in the closing process reaches micron level, which effectively avoids material deformation and dimensional deviation, and provides a solid guarantee for the accurate molding of the fan shell.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Shandong Zhongyou Heavy Industry Fan (FRP) shell forming hydraulic press combines the latest hydraulic transmission and control technology to achieve high precision and high stability of FRP materials.