Head stampingforming hydraulic pressAdvanced structural design, four-column structure or prestressed frame structure has high rigidity and high strength, which can effectively ensure the stability and reliability of the equipment in work. Through accurate manufacturing process and high-quality parts, it can ensure that the dimensional accuracy of stamping parts reaches a higher standard, meet the requirements of head accuracy, and have strong anti-offset load capacity. The four-angle and eight-sided plane guide rail can effectively resist offset load and make the equipment run more smoothly, can quickly complete the head of the stamping forming, centralized control button or PLC control system, with adjustment, manual and semi-automatic and other operations.

It is mainly used for the production of cold-pressed heads of various tankers, which can realize the forming, stretching and correcting processes of medium and thin plates, and is suitable for the pressing and molding of simple powder products and plastic products, etc;Head stamping hydraulic press adopts advanced hydraulic system drive, through the hydraulic cylinder to apply uniform and adjustable pressure, the mold can be replaced according to different needs, to adapt to different shapes and sizes of head production, high flexibility, head stamping hydraulic press can efficiently use energy, reduce energy waste. Compared with traditional machining equipment, its energy consumption is lower.

Head stamping hydraulic press is suitable for pressure vessel industry, such as the manufacture of all kinds of pressure vessel head, chemical equipment field, used in the production of chemical container head, automobile manufacturing, can process large automobile covering parts, such as ships, aviation, aerospace and rail and other fields of related parts processing.

Machinable materials include carbon steel, low alloy steel, stainless steel, stainless composite steel plate, etc., which are mainly used for cold and hot forming and pressing of various pressure vessel heads, as well as pressing drum, hemming and leveling processes of various thick and thin steel plates. Support rapid mold replacement, equipped with advanced electrical control system, realize fixed process and fixed pressure two molding processes, working pressure and stroke can be adjusted according to process requirements, automatic feeding, workpiece transfer, forging unloading, etc. can be customized to improve the automation and efficiency of the production line.

Commonly used are 315 tons, 400 tons, 500 tons, 630 tons, 800 tons, 1000 tons, 1250 tons, 1500 tons, 1800 tons, 2000 tons, 2500 tons, 3000 tons, 3500 tons, 4000 tons, 4500 tons, 5000 tons, 5500 tons, etc., through the sliding beam to drive the annular edge pressing die to generate edge pressing force. Therefore, it is also known in the industry as a non-offset head stretching machine.

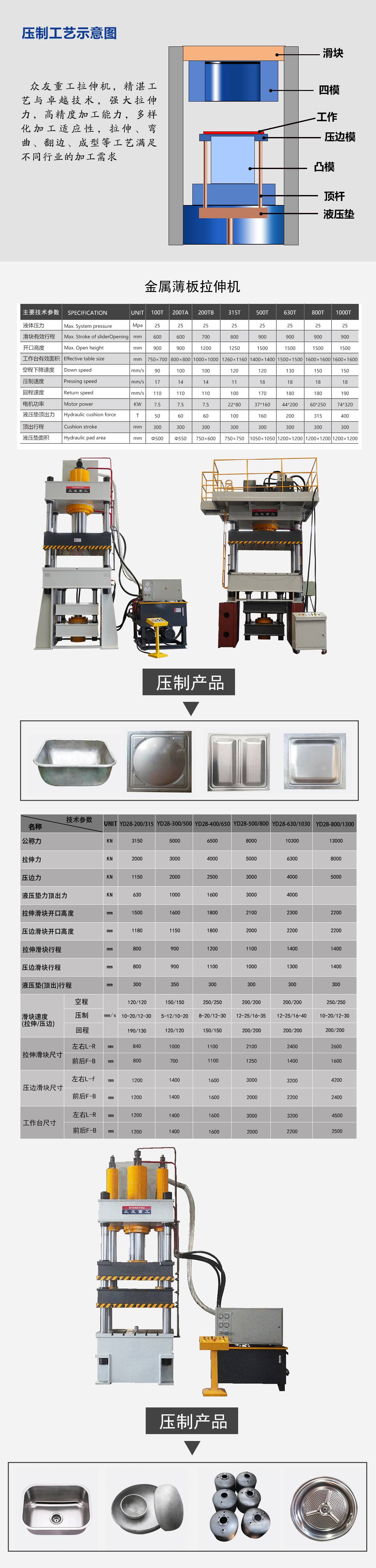

The equipment structure generally adopts a multi-rod ejection hydraulic press with a hydraulic pad, which has significant advantages in the field of head stamping forming, improving forming accuracy, improving production efficiency, and reducing production costs. It is widely used in the stamping, bending, flanging, and stretching of metal materials. In other processes, it is especially suitable for the manufacture of heads, containers, auto parts and other products.

The multi-rod ejection system can simultaneously ejector the workpiece through multiple ejector rods after the stamping forming is completed, ensuring that the workpiece is taken out smoothly and without deformation; compared with single-rod ejection, the multi-rod ejection system is more evenly stressed, which can effectively prevent the workpiece from being twisted or deformed during the ejection process, and improve the yield and quality of the product.

The hydraulic cushion system is located under the workbench, and the hydraulic cylinder provides a stable supporting force to ensure the stability of the workbench and the mold during the stamping process; the size of the supporting force can be adjusted as needed to adapt to different materials, thicknesses and shapes of the workpiece Processing requirements. At the same time, it can also play a buffering role in the stamping process, reduce shock and vibration, and protect the mold and equipment.

The process flow of the head stamping hydraulic press is mainly divided into the following pieces: mold installation-material preparation-positioning plate-slider down-stamping forming-pressure holding-slider return-head removal.

According to the size and shape requirements of the head, a suitable mold is customized, and the upper mold and the lower mold are installed on the slider and workbench of the hydraulic press respectively. During the installation process, ensure that the mold is firmly fixed and accurately positioned to ensure the stamping accuracy, select appropriate plate materials, and carry out blanking according to the specifications and material requirements of the head to ensure that the plate size meets the requirements. Place the prepared plate on the lower mold on the workbench, and position the plate through the positioning device to ensure the accurate position of the plate during the stamping process. Start the hydraulic press, and the slider quickly descends under the drive of the hydraulic system, when the slider is close to the plate, it is switched to the slow working mode to control the stamping speed and avoid excessive impact on the plate. After the head is stamped and formed, a certain pressure is maintained to ensure the shape stability and dimensional accuracy of the head.

Head hydraulic press is widely used in petrochemical, pressure vessel, aerospace, nuclear power, shipbuilding and other fields. It is committed to the technical research and development and innovation of head hydraulic press to meet the market demand.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Select high-quality materials and parts to ensure the durability and stability of the equipment, strict quality control system, strict control of each process, to ensure that product quality meets the relevant standards and requirements.