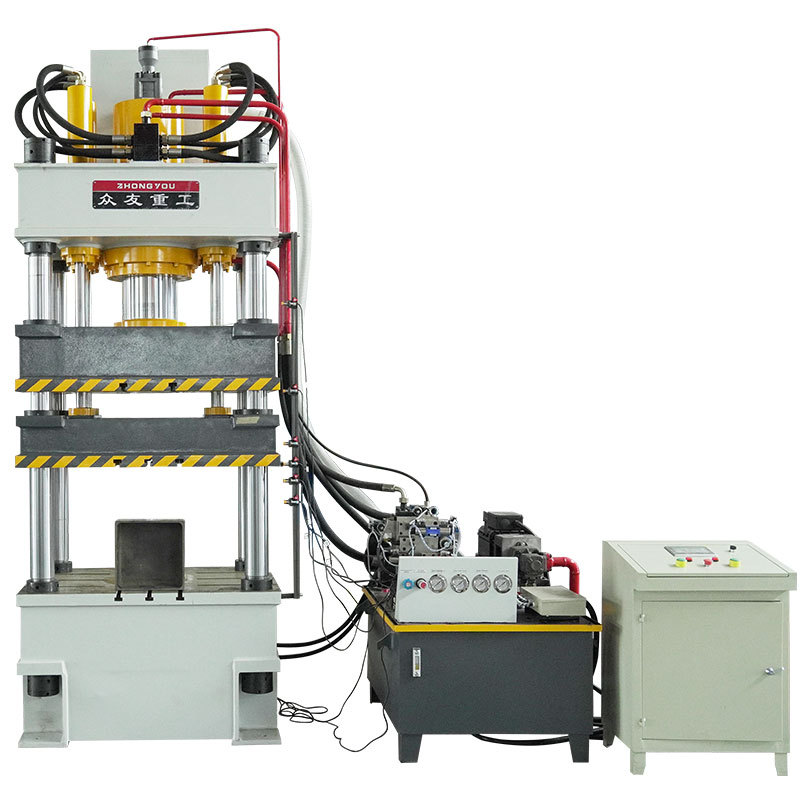

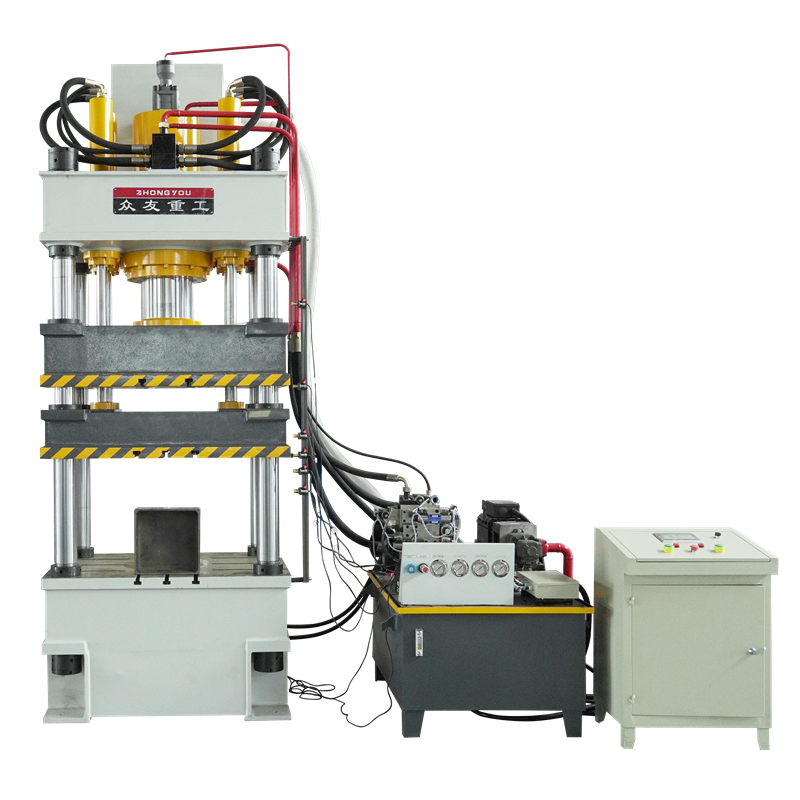

Crucibleforming hydraulic pressThe use of advanced hydraulic system and precision mechanical structure to ensure that the equipment can provide stable and accurate pressure during operation, to ensure the dimensional accuracy and quality stability of the crucible molding, equipped with high-precision displacement sensors and pressure sensors, real-time monitoring and feedback The operating status of the equipment realizes accurate pressure control and displacement control.

Optimized hydraulic system design, reduce energy loss, improve energy efficiency, reduce equipment operating costs, fast working cycle and efficient molding speed, can significantly improve production efficiency, meet the needs of large-scale production, with high tonnage pressing capacity, according to the requirements of different specifications and materials of the crucible, to provide sufficient pressure to ensure the density and strength of the crucible molding.

It can be equipped with an automatic control system to realize the automatic operation of the equipment, including automatic feeding, automatic pressing, automatic demoulding and other functions, reducing manual operations, and improving production efficiency and product quality consistency.

The crucible forming hydraulic press adopts advanced hydraulic system and precise mechanical structure to ensure the dimensional accuracy and quality stability of crucible forming. It is equipped with high-precision displacement sensors and pressure sensors to monitor and feedback the operating status of the equipment in real time to achieve accurate pressure control And displacement control, equipped with an automatic control system to realize the automatic operation of the equipment, including automatic feeding, automatic pressing, automatic demoulding and other functions.

Widely used in refractory industry, ceramic industry, scientific research fields, etc., can produce graphite crucible, silicon carbide crucible, alumina crucible, etc., used in metallurgy, chemical industry, glass and other high temperature industries; can be used to manufacture ceramic crucible, used in ceramic materials firing and experiments; in scientific research experiments, commonly used in the preparation of various special materials crucible, to meet the needs of different experimental conditions.

Support refractory powder, such as graphite powder, silicon carbide powder, high bauxite powder ceramic powder, such as alumina powder, zirconia powder pressing molding

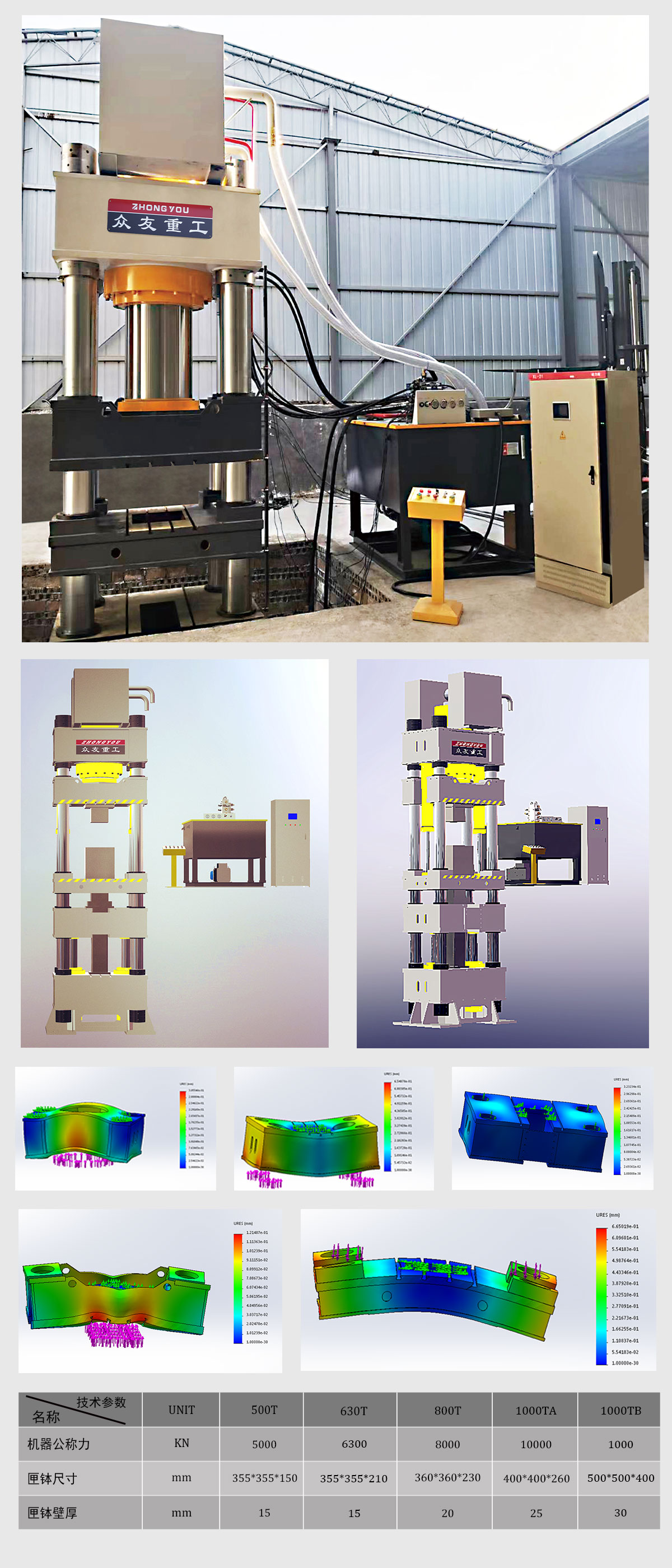

The crucible forming hydraulic press is mainly a four-beam four-column structure with stable structure and can withstand greater vertical pressure. It is suitable for metal crucibles of different shapes and specifications, such as round and square forming. The four-column structure can ensure the parallelism and verticality of the mold during the up and down movement, thereby improving the forming quality of the crucible.

The advanced PLC control system and man-machine interface are adopted to realize the full automation of the crucible forming process. It is suitable for the forming of crucibles made of various materials, such as ceramic crucibles, graphite crucibles, metal crucibles, etc. For graphite crucibles, hydraulic press can provide sufficient pressure to press graphite powder to produce graphite crucibles with good thermal conductivity and high temperature resistance, which are widely used in non-ferrous metal smelting and other fields.

We provide professional installation and commissioning services, and operate in strict accordance with the equipment installation manual and related standards to ensure that the equipment is firmly installed and stable. In the process of debugging, the parameters of the equipment are optimized and adjusted to make the equipment reach the best working state.

Graphite crucible forming hydraulic press is a hydraulic equipment used for graphite crucible forming. The manufacturing process of graphite crucible forming hydraulic press involves many links, including material selection, processing, assembly, debugging, etc. In the manufacturing process, it is necessary to strictly control the quality of each process to ensure the overall performance and reliability of the equipment. Specific manufacturing processes include:

The hydraulic press uses high-strength, high-wear-resistant, and corrosion-resistant materials to make structural parts such as the fuselage, columns, beams, brand hydraulic components and electrical components to ensure the performance of the hydraulic system and electrical control system, and adopts advanced machining equipment and technology., The structural parts are finished to ensure the dimensional accuracy and surface quality of each part.

Assemble the processed components, debug the hydraulic system and electrical control system to ensure the normal operation of the equipment, operate in strict accordance with the assembly process, and ensure the matching accuracy and sealing performance between the components. We will debug and test the assembled equipment to check whether the performance indicators meet the design requirements and ensure the stable operation of the machine.

Shandong Zhongyou Heavy Industry Machinery Equipment Co., Ltd. welcomes customers to the manufacturer for on-site inspections. Customers can visit the production workshop to understand the production process of the crucible forming hydraulic press, including processing technology, quality inspection and other links.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

We provide test machine service, which can show the whole process of equipment pressing crucible, including raw material preparation, formula modulation, mold selection, pressing molding, demoulding treatment, etc.