ShandongZhongyou Heavy IndustryMechanical Equipment Co., Ltd. Steel wood door embossing hydraulic press, also known as door embossing machine or deep embossing hydraulic press, is one of the main equipment of the door embossing process. It is specially designed for embossing of steel wooden doors, security doors, interior doors and other door panels. It can efficiently and accurately complete the embossing, embossing, embossing, engraving and other decorative processes of the facade, making the facade more delicate and beautiful, and enhancing the added value of the product.

The use of advanced hydraulic system, can achieve high precision pressure control, to ensure that the pressed out of the pattern and texture fine, clear.

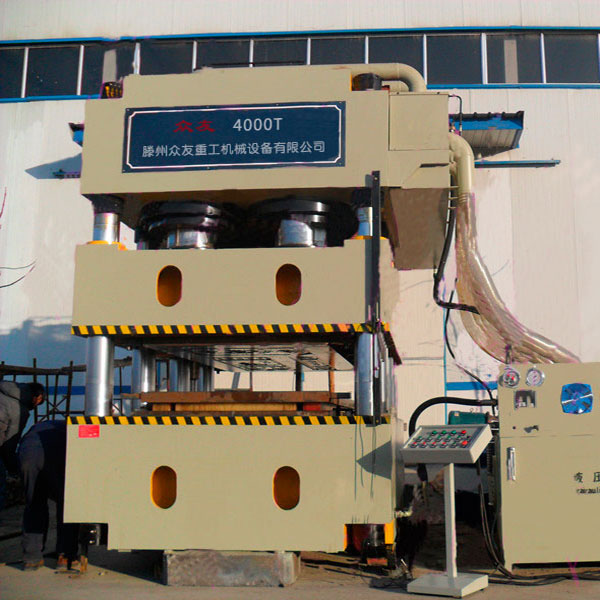

Provide a variety of tonnage specifications, such as 2000T, 2400T, 2500T, 3000T, 3600T, 4000T, 5000T, etc., to meet the production needs of different customers. Steel wooden door embossing hydraulic press is widely used in security doors, steel wooden doors, interior doors, iron doors, fire doors and other door panel embossing molding. Through the high-precision, high-pressure hydraulic system, the oil pressure is applied to the mold on the workbench, so that a variety of exquisite patterns and textures are pressed on the facade to enhance the market competitiveness of the product.

Steel wood door embossing hydraulic press is used for steel wood door surface embossing treatment of mechanical equipment, steel wood door embossing hydraulic press usually eight column or frame structure, with high strength, high rigidity characteristics.

When the machine is started, the hydraulic system will generate high pressure oil pressure through the oil cylinder, which will act on the mold on the workbench. The steel door to be processed in the mold will be squeezed by high pressure, thus forming a pattern corresponding to the mold on the door. And texture; high pressure output ensures the depth and clarity of the texture, so that the product has a better appearance quality.

Advanced hydraulic transmission technology and control system can realize high-precision embossing treatment; high degree of automation can significantly improve production efficiency. By replacing different molds, embossing treatment of various patterns and textures can be realized. The overall structure of the equipment is stable, the anti-partial load capacity is strong, and the stable performance can be maintained during long-term work. Application field Steel wooden door embossing hydraulic press is widely used in the door and window decoration industry, especially the surface decoration treatment of steel wooden doors, security doors and other products. Through embossing, the aesthetics and added value of the product can be significantly improved to meet the market demand for high-quality doors and windows.

The hydraulic system of steel wood door embossing hydraulic press is the core power source of the whole equipment. The hydraulic oil is transported to each hydraulic cylinder through the hydraulic pump to realize pressure transmission and energy conversion. It has the characteristics of high precision and high pressure output, which can meet the strict requirements of pressure and precision of steel wood door embossing process.

The frame and the worktable are the main structure of the equipment, usually made of high-strength steel, with sufficient rigidity and stability to withstand the huge pressure generated by the equipment during operation; the worktable is located at the bottom of the frame to support and fix the workpiece (I. e. the steel wooden door panel to be embossed). A fixture or mold is provided on the workbench to fix the workpiece and transmit hydraulic pressure.

The slider is a component that moves up and down the equipment and is driven by a hydraulic cylinder. A mold is installed on the slider, and the shape and pattern of the mold determine the final embossing effect.

Equipped with advanced PLC control system, used to control the process of pressure, speed and position and other parameters, with a high degree of automation and intelligent level, the equipment is equipped with multiple safety devices, such as emergency stop button, protective cover, safety light curtain, etc., strictly abide by the relevant national safety standards and norms, to ensure that the equipment in operation to achieve the highest safety performance.

Before starting work, check whether the various parts of the steel wooden door embossing hydraulic press are normal, including hydraulic system, electrical system, mold, etc. Ensure that the equipment is in good operating condition.

Prepare raw materials: prepare the steel and wooden door panels that need to be embossed to ensure that the surface is clean and smooth, free of oil, dust and other impurities

Adjust the parameters: set the pressure-adjust the speed-determine the stroke, according to the steel door plate material and thickness, and embossed pattern requirements, set the appropriate parameters.

Embossing operation: Place the prepared steel and wooden door plate on the mold to ensure that the position between the plate and the mold is accurate.

Press the start button, the steel and wood door embossing hydraulic press starts to work, the hydraulic system provides strong pressure, the mold is pressed on the plate, so that the surface of the plate to form the required pattern, need to maintain a certain pressure time to ensure the depth and three-dimensional sense of the pattern.

At the end of the holding time, the hydraulic system unloads the pressure, the mold is separated from the plate, and the steel and wooden door plate is formed.

The company cooperates with many domestic research institutes and many famous foreign brand companies to maintain the domestic technical advantages in line with international standards, and always adheres to the corporate tenet of quality, service and integrity!

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products