The train door shaping hydraulic press often has a three-beam and four-column structure, equipped with automatic devices such as multi-rod ejection devices and manipulators to achieve efficient shaping and repair operations. It is widely used in the field of repair and maintenance of train trucks and can repair various Types and sizes of truck door panels, including side doors, tailgates, etc.

The train door shaping hydraulic press adopts high-precision hydraulic control system and mechanical structure, which can ensure the accuracy and stability in the shaping and repair process. The equipment has fast movement speed and response ability, and can complete the shaping of multiple door panels in a short time Repair operations to improve production efficiency.

The hydraulic press adopts a closed hydraulic system, which has the characteristics of good stability, fast response speed, energy saving and environmental protection, reduces energy consumption and emissions, and has a reasonable equipment structure design, easy maintenance and maintenance, and reduces maintenance costs and downtime.

The train door shaping hydraulic press works through electrical and hydraulic transmission systems. It uses hydraulic oil as a medium to apply pressure to the train door panel through the interaction of the cylinder body and the cylinder rod, thereby restoring it to its original shape and size. The equipment is equipped with advanced hydraulic control system and electrical control system, which can realize precise pressure control and automatic operation.

The train door plastic hydraulic press is mainly used in the field of repair and maintenance of train trucks. It is suitable for the plastic repair of various types and sizes of truck door panels. Through plastic repair, the function and appearance of the door panel can be restored, the service life can be prolonged, and the train can be improved. Safety and operating efficiency.

With the continuous development of the railway transportation industry, the market demand for train door plastic hydraulic presses is also increasing. At present, there are many manufacturers in the market that produce and sell train door plastic hydraulic presses, and the product performance and quality are different.

When customers choose products, they need to consider comprehensively according to their own needs and budget, and choose products with high cost performance.

The train door reshaping hydraulic press usually adopts a three-beam and four-column structure. The upper, middle and lower three beams and four columns form a rigid frame. This structure not only has high stability, but also can resist large eccentric load. The lower beam is usually used as a workbench to carry the reshaped train door panel. The middle beam (also called sliding beam) is the main source of pressure and moves up and down through the push of hydraulic cylinders; the upper beam plays a supporting and fixing role.

The system uses hydraulic oil as the transmission medium. The hydraulic transmission system has the advantages of fast response speed, large load stiffness and high control accuracy. The equipment is equipped with advanced electrical control system to realize the precise control of the hydraulic transmission system. The electrical control system usually includes PLC control unit, touch screen operation interface, etc., which can realize one-key operation, automatic control and other functions.

It can be equipped with safety protection devices, infrared safety gratings, hydraulic safety bolts, safety shields, etc. The three-beam four-column structure has high stability and adaptability. It can be customized according to actual needs to meet the special needs of different customers.

The working principle is as follows;

1. Preparation: Prepare the train door panel to be repaired, check the damage and determine the repair method that needs to be carried out. 2. Mold preparation: According to the shape of the door panel and repair requirements, select the appropriate mold or fixture and install it on the hydraulic press. 3. Door panel positioning: Place the door panel between the mold or fixture to ensure the correct position and alignment. 4. Shaping repair: start the hydraulic press and apply pressure to the door panel for shaping repair. During the repair process, parameters such as pressure and speed can be adjusted as needed. 5. Inspection and evaluation: After the repair is completed, check and evaluate the door panel to ensure that the repair effect meets the requirements. 6. Follow-up treatment: surface treatment, cleaning and painting of the repaired door panel as needed to protect and beautify the door panel.

The train door shaping hydraulic press is mainly used in railway vehicle manufacturing and maintenance enterprises to reshape and repair the deformed train door. Hydraulic press can also be used for other large metal components shaping processing, has a wide range of applications.

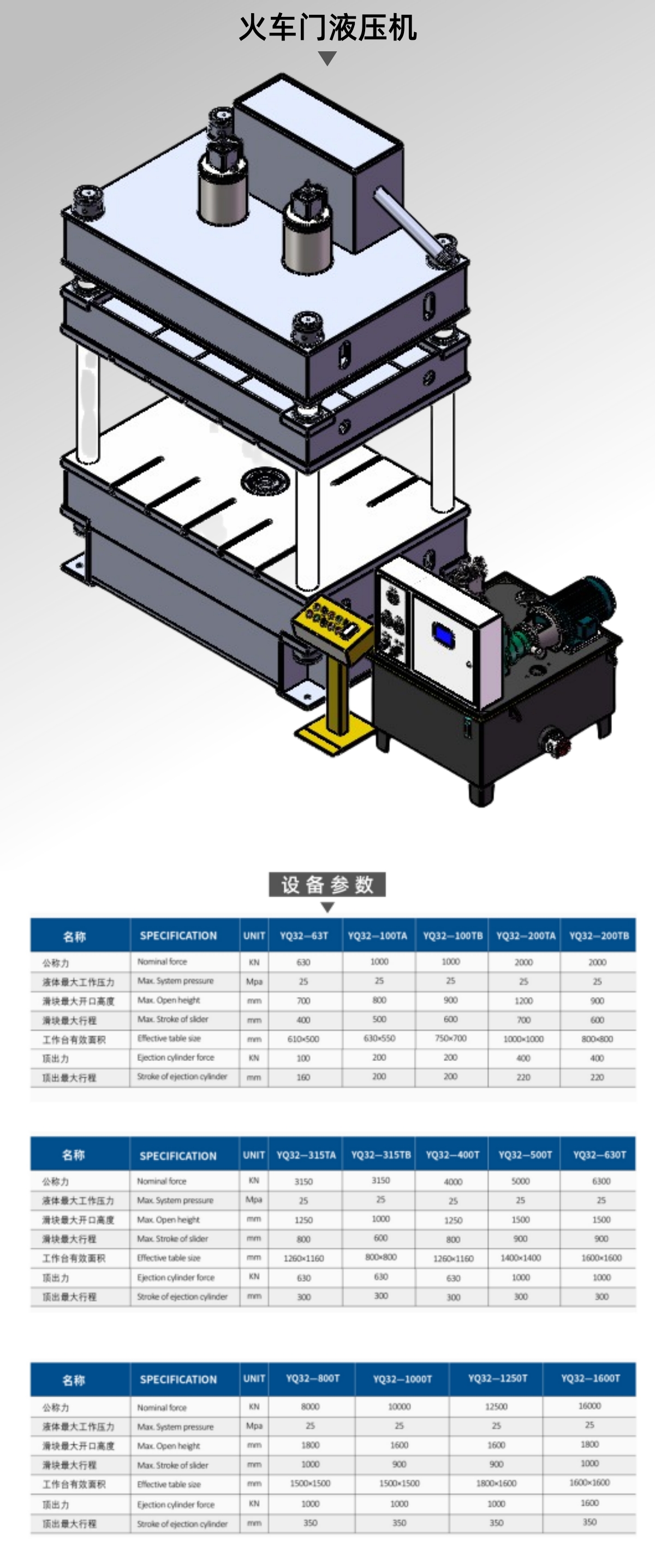

The train door hydraulic press has high pressure, large workbench area, high precision control, high automation level and flexible adjustable process parameters, which can efficiently and accurately complete the shaping and repair of train door panels.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

The pressing process of the train door plastic hydraulic press vividly shows the efficient plastic process and visually verifies the repair effect.