ShandongZhongyou Heavy Industrysheet metalTensile hydraulic pressWith strong stretching ability, can easily cope with all kinds of thickness of sheet metal stretching operation. The output pressure of the equipment is stable and uniform, which can ensure that the metal sheet is under consistent force during the stretching process, thereby effectively avoiding uneven stretching, wrinkling and other problems, greatly improving the quality and yield of the product, and adopting advanced hydraulic control The system has extremely fast response speed and high operation accuracy. According to different sheet metal materials and stretching process requirements, flexible adjustment of pressure, speed and other parameters, to provide you with personalized solutions to meet diversified production needs.

Efficient production enhances the competitiveness of enterprises. The sheet metal stretching hydraulic press has efficient production capacity and can complete a large number of sheet metal stretching tasks in a short time. This can not only save you time and cost, but also improve the production efficiency of enterprises, so that you have an advantage in the fierce market competition.

Widely used to meet the needs of different industries. Our equipment is suitable for the drawing and processing of various metal sheets, such as stainless steel plates, aluminum plates, copper plates, etc. Widely used in automobile manufacturing, home appliance manufacturing, hardware products and other industries, to meet the individual needs of different customers.

Shandong Zhongyou Heavy Industry's sheet metal stretching hydraulic press has strong stretching ability and can easily cope with sheet metal stretching operations of various thicknesses. The output pressure of the equipment is stable and uniform, which can ensure that the metal sheet is under consistent force during the stretching process, thereby effectively avoiding uneven stretching, wrinkling and other problems, greatly improving the quality and yield of the product, and adopting advanced hydraulic control The system has extremely fast response speed and high operation accuracy. According to different sheet metal materials and stretching process requirements, flexible adjustment of pressure, speed and other parameters, to provide you with personalized solutions to meet diversified production needs.

Efficient production enhances the competitiveness of enterprises. The sheet metal stretching hydraulic press has efficient production capacity and can complete a large number of sheet metal stretching tasks in a short time. This can not only save you time and cost, but also improve the production efficiency of enterprises, so that you have an advantage in the fierce market competition.

Widely used to meet the needs of different industries. Our equipment is suitable for the drawing and processing of various metal sheets, such as stainless steel plates, aluminum plates, copper plates, etc. Widely used in automobile manufacturing, home appliance manufacturing, hardware products and other industries, to meet the individual needs of different customers.

The body of the sheet metal stretching hydraulic press is welded with high-strength steel to form a strong and stable frame structure. This design can withstand huge tensile forces to ensure that there will be no deformation or shaking during work.

Stiffener design Stiffeners are arranged in key parts to further enhance the rigidity and stability of the fuselage. The reasonable layout of the reinforcing ribs can effectively disperse the stress and improve the overall strength of the equipment.

High-performance hydraulic pump is selected to provide a powerful power source for the equipment. The hydraulic cylinder made of high-quality steel has good sealing and wear resistance. It is equipped with advanced hydraulic valve group to control the flow direction, pressure and flow of hydraulic oil. High-quality oil pipes and joints ensure the sealing and reliability of the hydraulic system.

The electrical control system includes a programmable controller (PLC), a touch screen, etc. The electrical control system has the characteristics of high stability and convenient operation, which can realize the automatic control of the equipment.

There are a variety of safety protection devices, such as overload protection, limit protection, emergency stop button, etc. These safety protection devices can stop running in time when the equipment is abnormal, and protect the safety of operators and equipment.

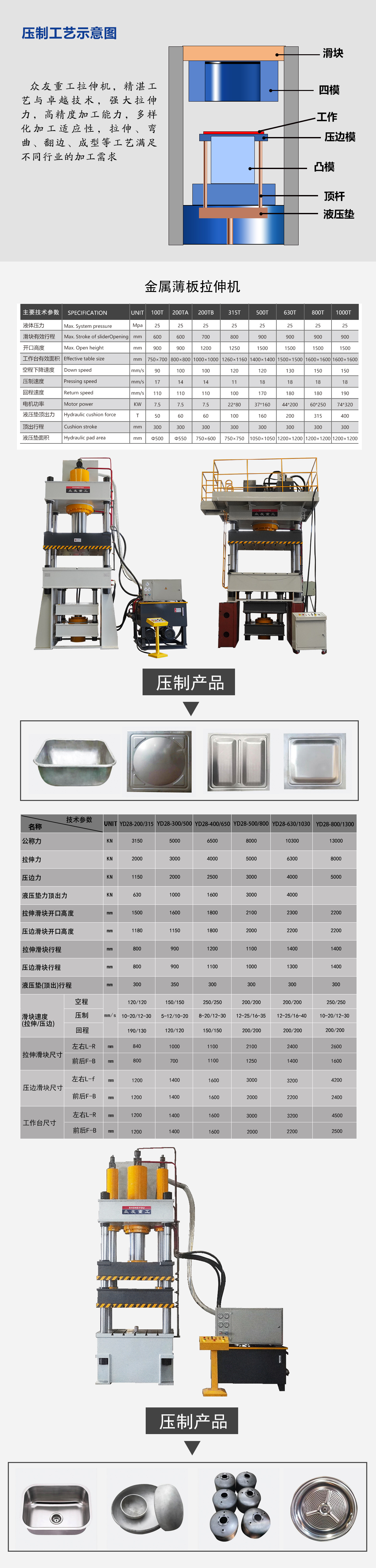

The process flow of the sheet metal drawing hydraulic press is as follows:

1. According to the shape and size of the sheet metal parts to be stretched, select the appropriate sheet metal material and check whether the surface quality and thickness meet the requirements. Necessary cleaning and pre-treatment of materials to remove oil and impurities on the surface.

2. Feeding: Place the metal sheet material on the mold to ensure that the material position is accurate.

Start the equipment: press the start button, the hydraulic press starts to work. The hydraulic system provides a strong tensile force, so that the metal sheet is gradually stretched under the action of the mold.

Process monitoring: During the stretching process, the control system monitors the operating status of the equipment in real time, including pressure, displacement, speed and other parameters, and observes the stretching of the metal sheet, such as whether there are wrinkles, cracks and other problems. If problems are found, the equipment parameters can be adjusted in time according to the actual situation, such as increasing pressure and reducing speed, to ensure the stretching effect.

3. Complete stretching: When the metal sheet is stretched to the required shape and size, the stretched metal sheet part is taken out of the mold by appropriate demoulding method. Care shall be taken to avoid damage to parts during demoulding.

The sheet drawing hydraulic press produced by Shandong Zhongyou Heavy Industry has undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products