ShandongZhongyou Heavy IndustryAs a professional manufacturer of hydraulic presses, Machinery Equipment Co., Ltd. has advanced production equipment and process equipment, such as large floor boring and milling machines, heavy lathes, milling planers, etc. The company designs and manages all computer networks, adopts CAD and CAPP computer-aided design, and has professional senior engineers and other technical personnel engaged in the research and development of new products and various special planes. The company cooperates with many domestic research institutes and many famous foreign brand companies to maintain the domestic leading technology advantage in line with international standards. The company always adhere to the quality first, service first, integrity first enterprise purpose. Each product of the factory enjoys the "Three Guarantees" service for one year and life-long maintenance. The company takes "sincerity", "letter", "fast" and "excellent" as its tenet, and provides users with high-quality products and services with preferential prices and comprehensive services.

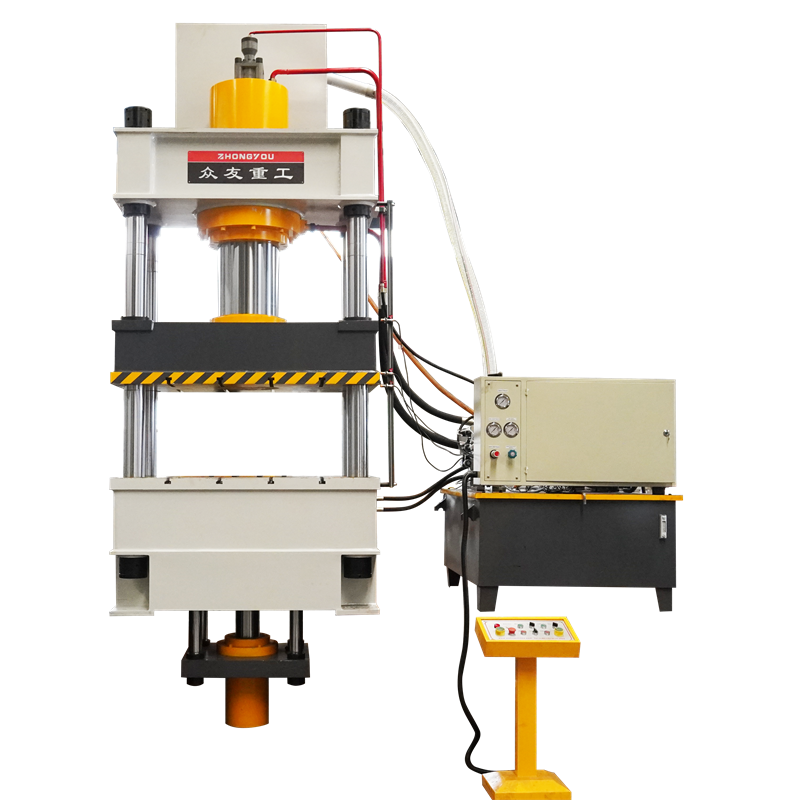

Metalforming hydraulic pressIt is mainly composed of four-column structure and frame structure, which can be customized according to demand. The hydraulic press can efficiently complete the stretching and bending of thin plates, and the stamping and forging of thick plates. It is equipped with an advanced control system, which can flexibly adjust the parameters according to different metal forming process requirements to achieve high-quality forming effects. Materials and advanced manufacturing technology have good rigidity and stability.

The metal forming hydraulic press is a heavy machinery and equipment designed for the pressing, forming, and stretching of metal materials. It uses advanced hydraulic transmission technology to drive working parts for various metal processing operations through the pressure energy of high-pressure liquid. The equipment is widely used in automobile manufacturing, aerospace, hardware tools, architectural decoration and other fields, and is one of the indispensable important equipment in the metal processing industry.

The precise hydraulic system and advanced control technology are used to ensure that the pressure, speed and other parameters in the processing process are accurately controllable, so as to achieve high-precision metal forming processing. Equipment structure design is reasonable, strong power, can quickly complete a variety of complex metal processing tasks, improve production efficiency. The use of high-quality materials and advanced manufacturing technology ensures that the equipment maintains stable performance during long-term operation and reduces the failure rate. Customized design can be carried out according to customer needs to adapt to different metal materials, different shapes and sizes of processing needs. It adopts advanced energy-saving technology and optimized hydraulic system design to reduce energy consumption and noise pollution, which is in line with the green production concept of modern industry.

The four-column structure design has the advantages of high stability, good precision and convenient operation. It is widely used in sheet metal stretching, bending, blanking and other molding processes, as well as plastic products, powder metallurgy and other industries.

Frame structure, strong rigidity, good anti-partial load capacity. The overall frame is welded with high-quality steel, which can withstand greater working pressure and eccentric load, and is suitable for forming large metal parts. Mainly used in automobile manufacturing, aerospace, shipbuilding and other fields of large metal structural parts stamping, forging, stretching and other forming processes.

Single column structure, compact shape, small footprint. Simple operation, suitable for small metal parts molding and assembly operations. Commonly used in hardware products, electronic appliances, instrumentation and other industries of small parts stamping, bending, press-fitting and other forming processes.

Gantry structure, with large working space and carrying capacity. The beams and columns are made of high-quality steel, with good rigidity and high precision, and are suitable for forming processes such as stamping and shearing of large metal plates. Mainly used for steel structure manufacturing, mechanical processing, power equipment manufacturing and other industries of large sheet metal forming processing.

Place the metal material to be formed on the mold, ensuring that the position and orientation of the material are correct.

Start the hydraulic press: press the start button of the hydraulic press to form the metal material. In the molding process, it is necessary to closely observe the operating status and molding conditions of the hydraulic press, and adjust the parameters in time to ensure the molding quality.

Holding pressure: when the pressure head of the hydraulic press reaches the predetermined position, maintain a certain pressure time, so that the metal material is fully formed in the mold. The length of the holding time depends on the nature of the metal material and the requirements of the molding process.

Pressure relief: After the pressure holding time is over, the hydraulic system starts to relieve pressure, and the pressure head of the hydraulic press moves upward and leaves the molded part.

Blanking: Remove the formed metal parts from the mold for quality inspection and subsequent processing. Can use manipulator, sucker and other automated equipment for blanking, improve production efficiency and safety.

According to the customer's metal forming needs, product design and process planning can be carried out to determine the required hydraulic machine model.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products