Tensile hydraulic pressFour-column structure, frame structure, divided into single-acting hydraulic press and double-acting hydraulic press, mainly used for metal sheet stretching processing, such as automobile panels, home appliance shells, containers, etc. Through drawing processing, the metal plate can be formed into parts of various shapes, and the utilization rate of the material and the strength of the parts can be improved. The stretching hydraulic press adopts advanced hydraulic system and control technology, which can provide stable pressure output. During the stretching process, the pressure fluctuation is small, which can ensure the stability of the processing quality.

Stretching hydraulic press has a wide range of applications in the field of automobile manufacturing, such as automobile panels, body structure parts, chassis parts, such as stretching processing. Home appliance shell, liner, bracket and other parts of the stretching processing is also inseparable from the stretching hydraulic press. In the field of aerospace, drawing hydraulic presses are used for the drawing processing of aircraft parts, spacecraft structural parts, etc. Stretching hydraulic press is also widely used in hardware products, plastic products, rubber products and other industries.

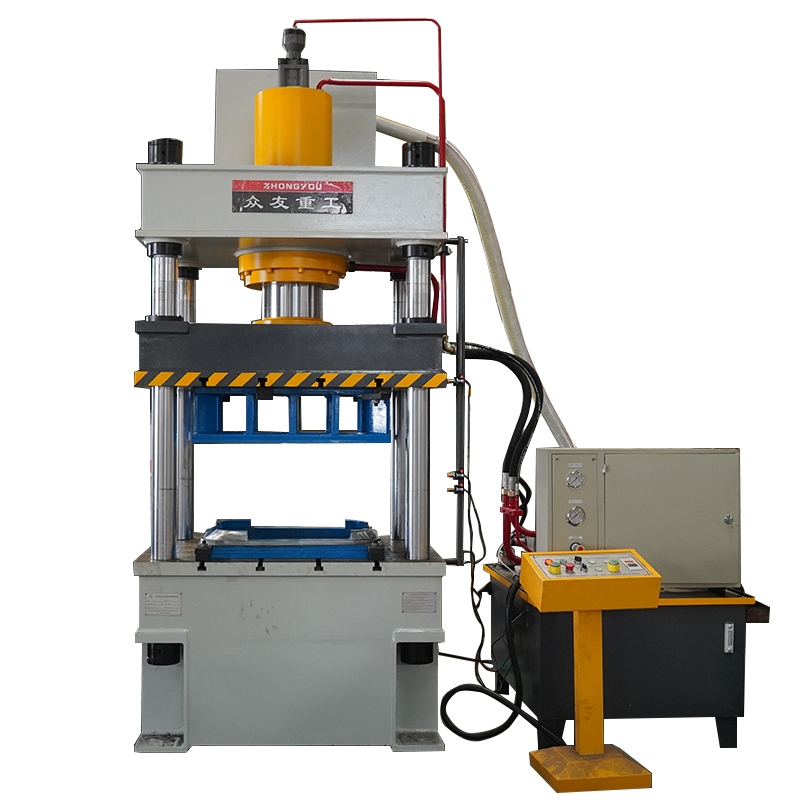

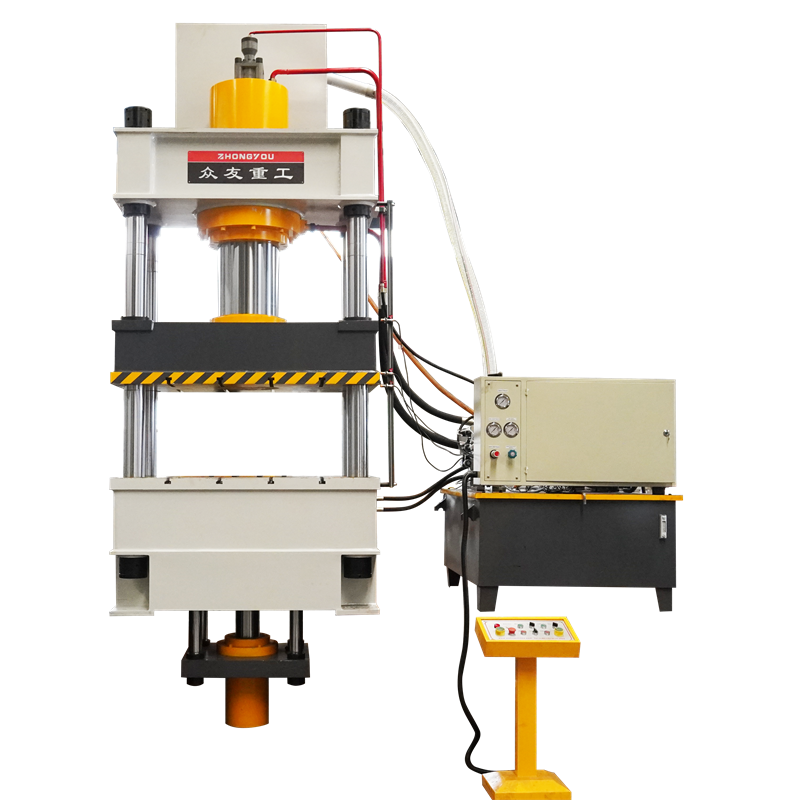

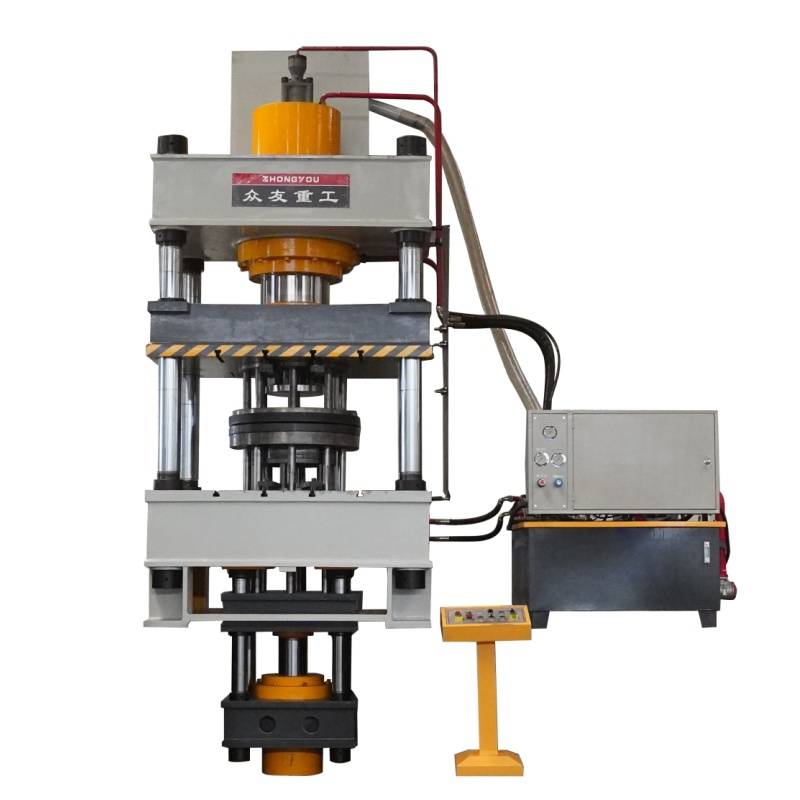

Hydraulic pad stretching hydraulic press is a commonly used stretching machine. It is a three-beam and four-column hydraulic press. The worktable is equipped with multi-rod ejection. The sliding beam is equipped with a feeding cylinder. It is mostly suitable for deep stretching processes, such as automobile sheet metal parts, automobile covering parts, stainless steel water tanks, stainless steel fan shells, stainless steel pots and pans, etc.

Hydraulic cushion device, hydraulic cushion is mainly able to prevent the material flow too fast during sheet metal forming caused by wrinkling or cracking, improve the product quality of drawing parts, reduce the scrap rate., It is especially suitable for various deep and shallow drawing processes to prevent wrinkling or cracking caused by too fast material flow during sheet metal forming and improve the drawing quality of the workpiece. In particular, it has a good auxiliary effect on the drawing of aluminum sheet and the pressing forming of aluminum products and the positive and negative drawing forming of stainless steel products in stainless steel products factory.

The hydraulic pad stretching hydraulic press adopts a three-beam and four-column structure. The fuselage is composed of an upper beam, a sliding beam, a workbench, a hydraulic pad, an ejector rod, an oil cylinder, an upright column, a liquid filling box, and a limiting mechanism. The 800-ton hydraulic cushion stretching hydraulic press is controlled by a servo system, and the stretching pressure, speed and displacement accuracy are well controlled to ensure that the stretched products are highly consistent. Hydraulic machine with PLC programmable controller and touch screen, can be intuitive to view some data and convenient to make timely adjustments. The operating button of the stretching hydraulic press is integrated on a movable button operating table, and its position can be moved at will within a certain distance range, which is convenient for operation.

The four-column stretching hydraulic press mainly adopts steel plate welding parts, which is treated by tempering vibration aging, and the frame design is analyzed by limited elements, which has high rigidity and high precision. It ensures the small deformation of the machine and is more convenient to use. Can also be specially customized before and after the movement of the workbench. According to the different choices of customers, the stroke height of the hydraulic cylinder can be customized according to customer requirements. Independent hydraulic pump station can provide powerful power. The anti-seismic pressure gauge and pressure regulating valve are installed on the pump station, which is convenient for users to observe and adjust the pressure of the machine at any time.

The stretch forming hydraulic press has an independent power mechanism and electrical system, and adopts button centralized control, which can realize three working modes of adjustment, manual and semi-automatic. The working pressure, pressing speed, no-load fast downward and deceleration stroke and range of the machine can be adjusted according to the process requirements, and the ejection process can be completed. There are three process modes of ejection process and stretching process, each of which is constant pressure, there are two kinds of process actions to choose from, and the constant pressure forming process has ejection delay and automatic return after pressing.

According to the material, thickness, shape and other factors of the workpiece, adjust the working parameters of the stretching hydraulic press, such as pressure, speed, stroke, etc. The adjustment of these parameters needs to be carried out according to actual experience and process requirements to ensure the smooth progress of the stretching process while ensuring the quality of the workpiece

After confirming that the equipment and the workpiece are ready, start the stretching hydraulic press. When the slider touches the workpiece downward, it starts to stretch the workpiece. During the stretching process, the operator needs to closely observe the operating state of the equipment and the deformation of the workpiece, Adjust the parameters in time to ensure that the stretching process is stable and uniform.

The stretching hydraulic press is used for stretching, bending and forming processes of metal plates. According to customer requirements, we can design and produce four-column and frame-type stretching hydraulic presses. We have single-acting sheet stretching hydraulic presses (YD27) and double-acting sheet stretching hydraulic presses (YD28).

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

From the selection of raw materials to the processing of parts, to the assembly of the whole machine, every link of the drawing hydraulic press is strictly controlled.