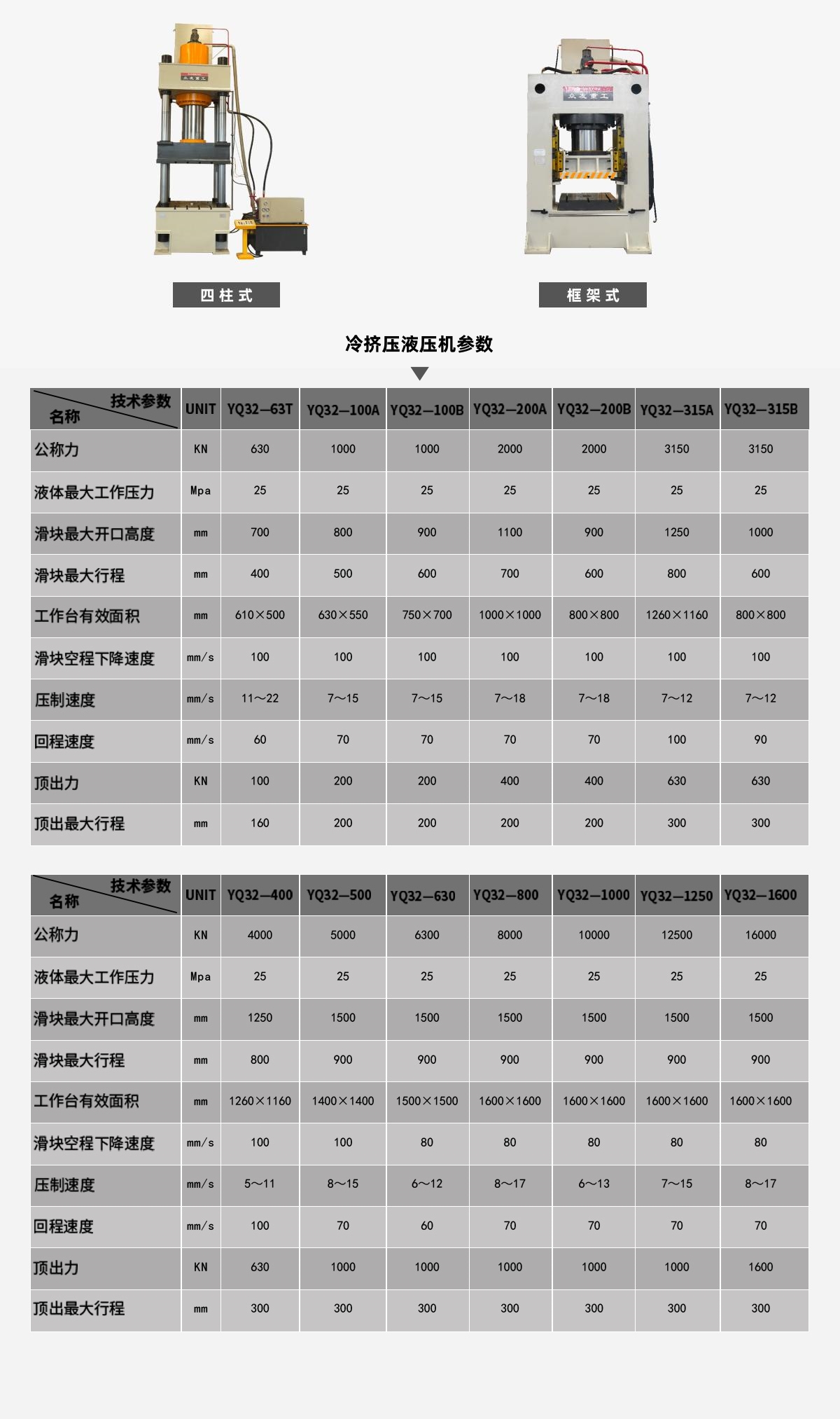

The structure of the cold-pressed hydraulic press can be either a four-column structure or a frame structure. The cold-pressed process is the process of extruding metal materials at room temperature. In the coldExtrusion hydraulic pressIn the working process, the metal material is put into the mold, and through the action of high-pressure oil, the metal material is plastically deformed and forced into the cavity of the mold, and finally forms the required shape and size. This process requires the hydraulic press to have high-precision positioning and movement capabilities to ensure the shape and dimensional accuracy of the product.

The cold extrusion process can realize the plastic deformation of the material at room temperature, reduce the material waste in the hot working process, and improve the utilization rate of the material;cold extrusion hydraulic pressUsually automatic control, can achieve rapid and continuous production, because the cold extrusion process of the material deformation is completed in the mold, so the shape and size of the product is high precision, to meet the needs of precision processing, cold extrusion hydraulic press is suitable for a variety of metal materials processing, including aluminum, copper, steel, and can produce complex shape, precise size of the product.

Cold-pressed hydraulic presses are widely used in many fields, such as the automobile manufacturing industry, which is used to produce engine blocks, gears, bearings and other parts to meet the needs of the automobile industry for high-precision and high-strength parts. In the manufacturing process of mechanical products such as machine tools, tools and molds; In the aerospace field, cold extrusion hydraulic presses are used to produce high-precision and high-strength structural parts and parts; electronic products industry, with the trend of precision and miniaturization of electronic products, the cold extrusion hydraulic press has also been widely used in the manufacture of electronic components.

The four-column structure is simple and has good stability. It is widely used in various processes such as stamping, pressing, straightening, bending, flanging, sheet stretching, etc. The guide structure mainly adopts round guide sleeve on the four columns, which is simple and reliable; the frame structure has the advantages of strong anti-deflection load capacity and high precision, which has become the ideal choice for high-precision pressing and large-scale workpieces. The guide structure is guided by surface bonding on the side column, and the bonding area between the guide block and the side column is larger, and the anti-bias load capacity is stronger. In the event of partial load, the stability of the hydraulic press can be maintained, and it is suitable for high-precision pressing and large-scale workpiece applications.

The four-column equipment structure usually adopts a three-beam four-column structure, that is, the upper, middle and lower three beams and four columns form a rigid frame. This structure makes the overall stability of the equipment high. The columns and beams are the main load-bearing components. After optimized design, the appearance is beautiful and economical. The electrical system is mostly controlled by PLC, which can realize one-key operation. The system also has the function of holding pressure delay, which can be adjusted according to the process requirements. The modulus of the end face of the three beams of the main machine is large, which improves the rigidity of the three beams. Key components such as the main cylinder and the piston rod are manufactured with excellent forgings.

The frame-type equipment structure adopts a frame-type frame welded with integral steel plates, which has extremely high overall rigidity and compressive strength. The upper beam, sliding block, worktable and other components are welded with high-quality steel plates, and the welding stress is eliminated through high-frequency vibration to ensure the stability and durability of the body structure. The high-precision guide structure enables the frame-type hydraulic press to realize high-precision positioning and movement during the pressing process, which is more suitable for high-precision pressing and large workpieces, such as precision processing, mold manufacturing and other fields.

The cold extrusion process uses the principle of metal plastic deformation to apply strong pressure to the metal in the extrusion die cavity at room temperature to extrude it from the die hole or the gap between the convex and concave dies, so as to obtain the required shape and Size of parts. In this process, the metal blank is subjected to three-way compressive stress in the mold, plastic flow occurs, and finally deforms according to the shape of the mold cavity. Technological process: blank making-annealing treatment-cold extrusion forming-subsequent treatment.

Die design is the key to the success of the cold extrusion process. The shape, size and precision of the die cavity directly affect the shape, size and precision of the final part; in the process of cold extrusion, it is necessary to precisely control the pressure applied to the metal blank; good lubrication and cooling conditions are important for reducing the deformation resistance of the material, improving the carrying capacity of the mold and extending the service life of the mold. The cold extrusion process has the advantages of high production efficiency, high material utilization, high precision of parts and the ability to process complex shape parts. Therefore, it is widely used in automobile, machinery, electronics, aerospace and other fields to produce parts of various shapes and sizes, such as gears, bearings, connecting rods, housings, etc.

Shandong Zhongyou Heavy Industry Cold Press is highly efficient, high-precision and multi-functional, which significantly improves production efficiency and product quality and meets diversified processing needs.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Our Shandong Zhongyou Heavy Industry strictly controls the selection of raw materials, and has passed ISO certification and quality inspection standards. The products have been strictly tested and the quality is reliable, and tailor-made solutions for customers.