Anchor tray stamping hydraulic press is stamping anchor tray forming equipment, in coal mines, mining, tunnel construction, groundwater engineering and other fields are widely used, anchor tray stamping hydraulic press usually adopts four-column or frame structure.

The fuselage is made of high-strength materials with high stability. The four columns ensure the precise guidance of the mold during the stamping process and improve the processing accuracy. The hydraulic transmission system includes hydraulic pump station, power system, valve block, valve parts, etc., through the hydraulic transmission to achieve the mold up and down movement and stamping action, electrical control system, the use of PLC programmable controller, to achieve automatic control of equipment. The hydraulic press has strong adaptability, and the anchor tray stamping hydraulic press can adapt to the processing requirements of anchor trays of different sizes, shapes and materials, and has high pressing accuracy.

By adjusting the parameters and working mode of the hydraulic system, the processing requirements of different workpieces can be realized, and one machine can be used for multiple purposes. The anchor pallet stamping hydraulic press is widely used in coal mines, mining, tunnel construction, groundwater engineering and other fields. It is mainly used for processing and producing mine bolt anchor cable trays for rock operations and underground operations.

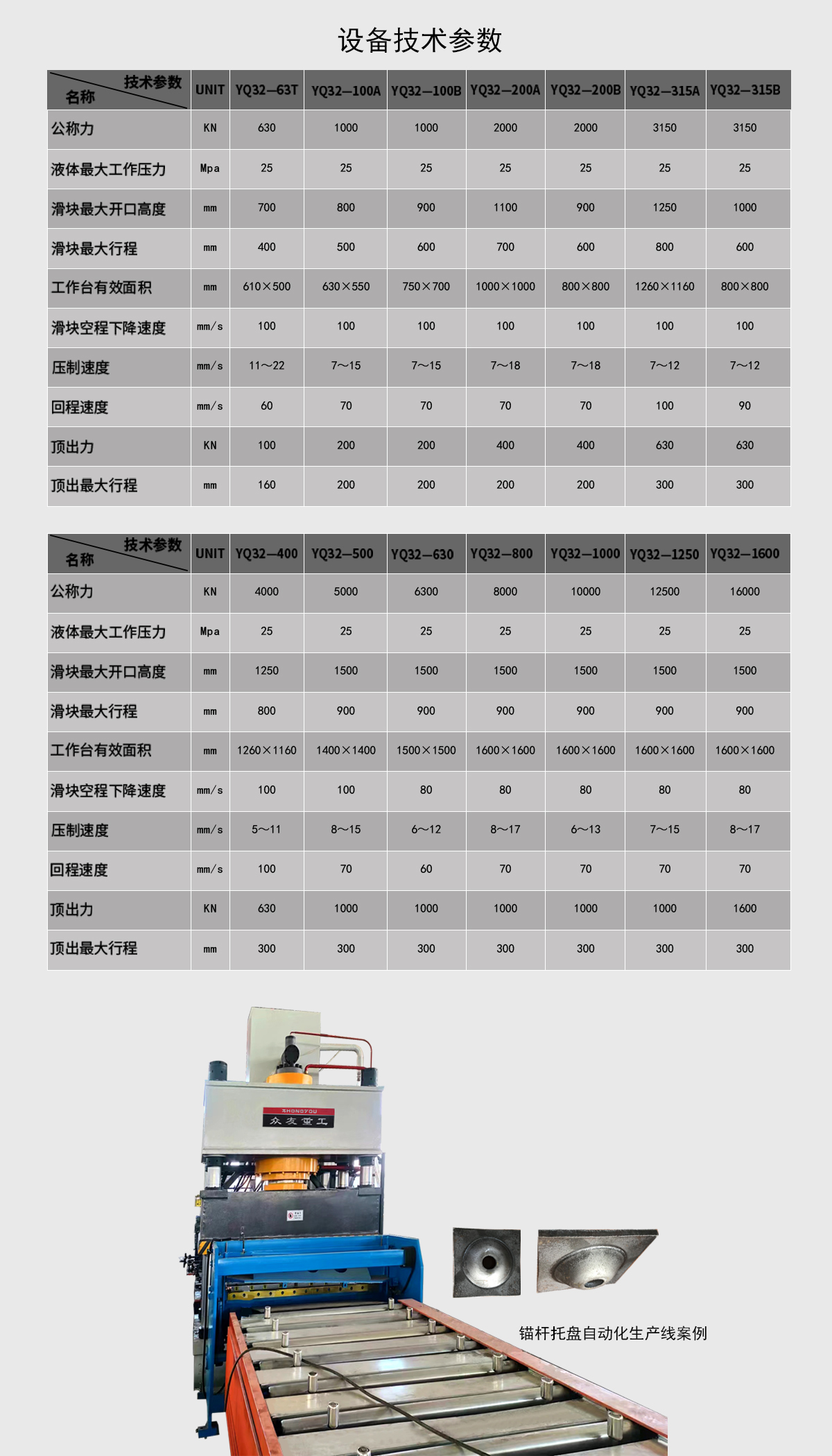

The bolt pallet stamping hydraulic press adopts an advanced hydraulic system, which can provide strong and stable pressure to ensure the efficient completion of the stamping of the bolt pallet. Whether it is a small pallet or a large pallet, it can easily deal with it. It is equipped with a precise control system. It can accurately control the pressure, stroke and speed parameters in the stamping process.

The bolt pallet produced has high dimensional accuracy, stable and reliable quality, fast stamping speed and short working cycle, which can greatly improve production efficiency and meet the needs of large-scale production. The fuselage is welded with high-strength steel, with firm structure and good stability, can withstand huge pressure without deformation, and ensure the long-term stable operation of the equipment. Hydraulic components of well-known brands are selected, such as hydraulic pumps, hydraulic cylinders, hydraulic valves, etc, ensure the reliability and stability of the hydraulic system.

Shandong Zhongyou Heavy Industry Anchor Pallet Stamping Hydraulic Press is suitable for the production of various types of anchor pallets, including round, square, rectangular and other pallets of different shapes. It is widely used in mines, tunnels, construction and other fields, providing reliable pallet products for bolt support in these industries.

The body of the bolt tray stamping hydraulic press is welded with high-quality steel, and the structure is firm and stable. After precision processing and strict quality testing, to ensure that the fuselage in the long-term use of the process will not be deformed. This high-strength fuselage can withstand huge pressure and provides a solid foundation for the stable operation of the equipment.

The high-performance hydraulic pump can provide stable and powerful pressure output.

The hydraulic cylinder has good sealing performance and can effectively prevent hydraulic oil leakage.

The electrical control system has the characteristics of high stability and strong reliability, which can ensure that the equipment will not fail during long-term operation. The equipment is equipped with a humanized operation panel, which is simple and convenient to operate.

Our molds are made of high-strength alloy steel, which has good wear resistance and corrosion resistance. The design of the mold has been carefully optimized to meet the stamping requirements of different specifications of anchor trays and ensure the stable quality of the stamped products. The installation of the mold adopts a quick mold change device, which is convenient and quick.

First of all, select the appropriate steel as the raw material according to the production needs. The steel should have good strength and plasticity to ensure the reliable quality of the stamped anchor tray.

1. The steel is blanking according to the predetermined size.

2. Install the mold: install the appropriate stamping mold on the hydraulic press. The installation of the mold should be firm and reliable to ensure that there will be no displacement or loosening during the stamping process.

3. Feeding: Place the prepared steel on the mold to ensure accurate position.

4. Start the hydraulic press: start the hydraulic press through the operation control system. The hydraulic cylinder of the hydraulic press starts to work, generating strong pressure, causing plastic deformation of the steel in the mold, and gradually forming into the shape of the anchor tray.

5. Return: After the pressure holding is completed, the hydraulic cylinder of the hydraulic press returns, and the molded anchor rod tray is taken out of the mold.

The automatic production line of anchor rod tray is a stamping processing equipment integrating automatic pushing, stretching, blanking and discharging. It can realize a forming process from steel plate to finished product, improve production efficiency, save labor cost and realize automatic production.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Anchor tray hydraulic press is a common equipment for automatic production of manufacturing enterprises. The automatic production line of anchor tray is designed to solve the problems of large production volume, many specifications and models, high labor intensity, low production efficiency and the like of anchor tray. It has high automation degree, many merging processes and flexible configuration schemes to meet actual needs. It can automatically complete all production processes of automatic feeding of raw materials, accurate sizing, truncation, punching and automatic stacking of anchor tray.