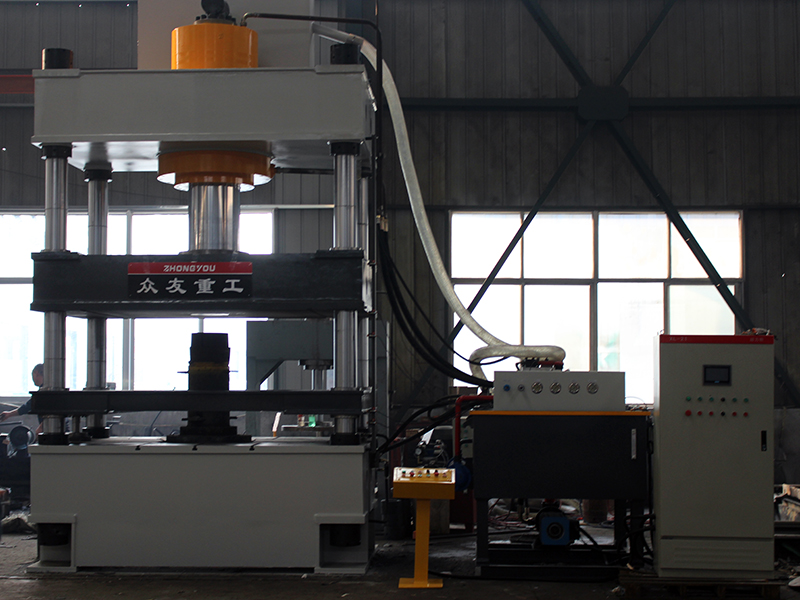

sawdust trayforming hydraulic pressThere are two types of four-column type and frame type. According to the production needs of different scales, we provide small hydraulic presses from entry-level to large industrial hydraulic presses with a wide range of tonnage coverage. The high tonnage design ensures that the pressed pallet is compact in structure and strong in carrying capacity, and is suitable for a variety of transportation and storage environments.

The use of advanced hydraulic technology to ensure the close combination of wood particles, high density and strength of finished pallets, the use of renewable wood resources, reduce wood consumption, in line with the concept of green production, automatic control system, to ensure that each pallet size is accurate, stable quality, efficient production, reduce unit cost, enhance market competitiveness.

It is suitable for wood processing, logistics warehousing, agricultural packaging and other fields. It provides 24-hour online customer service, quickly responds to customer needs, free installation and debugging, ensures the smooth production of equipment, provides customers with comprehensive operation training, and helps customers quickly master equipment use skills.

We provide customers with free test machine service. Customers can bring their own sawdust materials and molds to the manufacturer, and use the sawdust pallet forming hydraulic press for test machine operation under the guidance of professional and technical personnel.

The worktable size of the sawdust pallet forming hydraulic press provides a variety of specifications, the four-column structure is stable, and the guiding accuracy is high. It is suitable for producing high-precision, small and medium-sized sawdust pallets. For example, in the electronics, pharmaceutical and other industries, the dimensional accuracy and stability of the pallet are required to be higher, and the frame structure has higher rigidity and carrying capacity, which is suitable for the production of large and heavy sawdust pallets. Commonly used in chemical, machinery manufacturing and other industries.

Sawdust pallet forming hydraulic machine body is made of high strength steel plate welding, such as Q345 steel. After a special heat treatment process, the fuselage has good strength and toughness, can withstand the huge stress generated during the pressing process, and ensure the stability and reliability of the equipment; the hydraulic cylinder is generally made of high-quality alloy steel pipe, such as 42CrMo, and the inner wall is precision Machining and chrome plating treatment, with good wear resistance and sealing. The piston usually uses high-strength aluminum alloy or alloy steel to ensure that the hydraulic cylinder can operate efficiently and stably in a high-pressure environment.

Mold usually uses high hardness, high toughness die steel, such as Cr12MoV, H13 and so on. These die steel after quenching, tempering and other heat treatment processes, the hardness can reach HRC58-62, can withstand the high pressure and friction in the process of sawdust pallet pressing, and prolong the service life of the mold.

The hydraulic press can provide strong pressure to make the bonding between the sawdust closer, so that the sawdust pallet produced has higher strength. Compared with traditional pallets, its carrying capacity can be increased by 20% - 30% under the same size and weight.

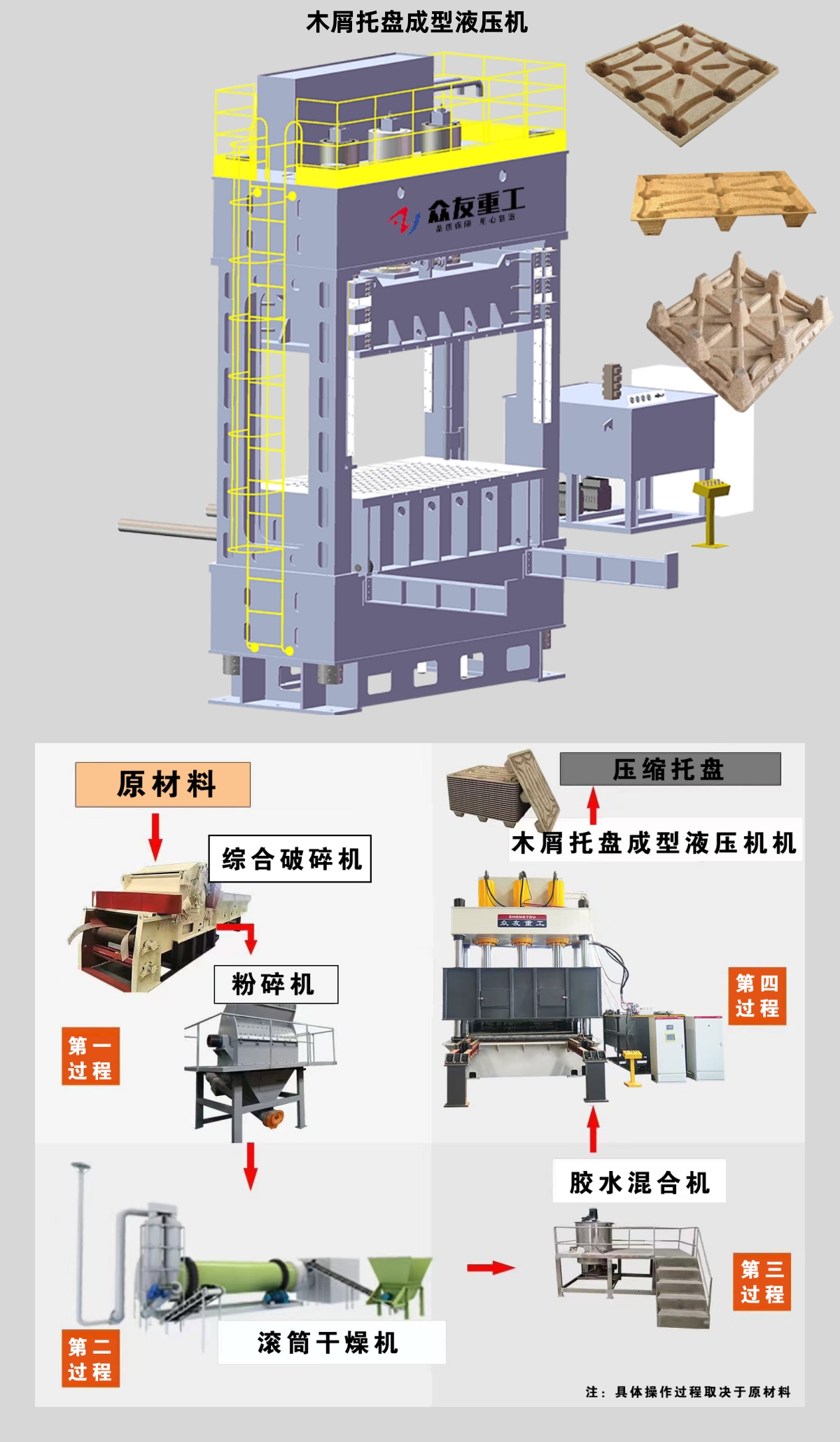

The process flow of sawdust pallet forming hydraulic press is as follows:

Choose the right raw materials: according to the production needs to choose the right wood chips, plastics or other composite materials as raw materials,

Pretreatment: preliminary cutting, chipping and crushing of raw materials to make them reach the size suitable for molding. Our company can match the crusher.

Drying: The broken raw materials are dried at high temperature to remove moisture and improve the plasticity of the material.

Mixing glue (for sawdust tray): The dried sawdust is evenly mixed with the adhesive in proportion to enhance the binding force of the material.

Paving: transport the mixed rubber to the paving machine according to the set quantity and lay it evenly in the mold.

Molding: Through the high temperature and high pressure treatment of the hydraulic press, the raw materials are molded in the mold at one time.

Post-processing: Take the molded tray out of the mold, and polish the corners to improve the appearance quality of the product.

Shandong Zhongyou heavy high-efficiency sawdust pallet molding hydraulic press, designed for modern, large-scale production design.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products