Double actionTensile hydraulic pressAdopting advanced hydraulic control system and precise guiding device, during the double-action stretching process, the cooperation of the inner and outer sliders can make the metal material deform evenly, avoiding the local excessive stretching of the material, so that the surface of the stretched product is smooth and flat, without defects such as wrinkles and scratches. The unique design of the inner and outer sliders can realize the stretching of complex shaped workpieces, for example, it can process auto parts with deep cavities and multi-curvature changes to meet the needs of modern industry for diversified product design.

The four-column double-acting stretching hydraulic press is suitable for the stretching of high-precision, small and medium-sized workpieces. For example, in the electronics and electrical industry, it is used for processing precision metal shells.

The frame-type double-action stretching hydraulic press has higher rigidity and bearing capacity, and is suitable for stretching large and heavy workpieces. Commonly used in automotive, aerospace and other fields of large parts production.

The company provides professional equipment installation and commissioning services, installation and commissioning engineers will go to the site in accordance with the relevant standards for equipment installation, installation and commissioning work to ensure the normal operation of the equipment.

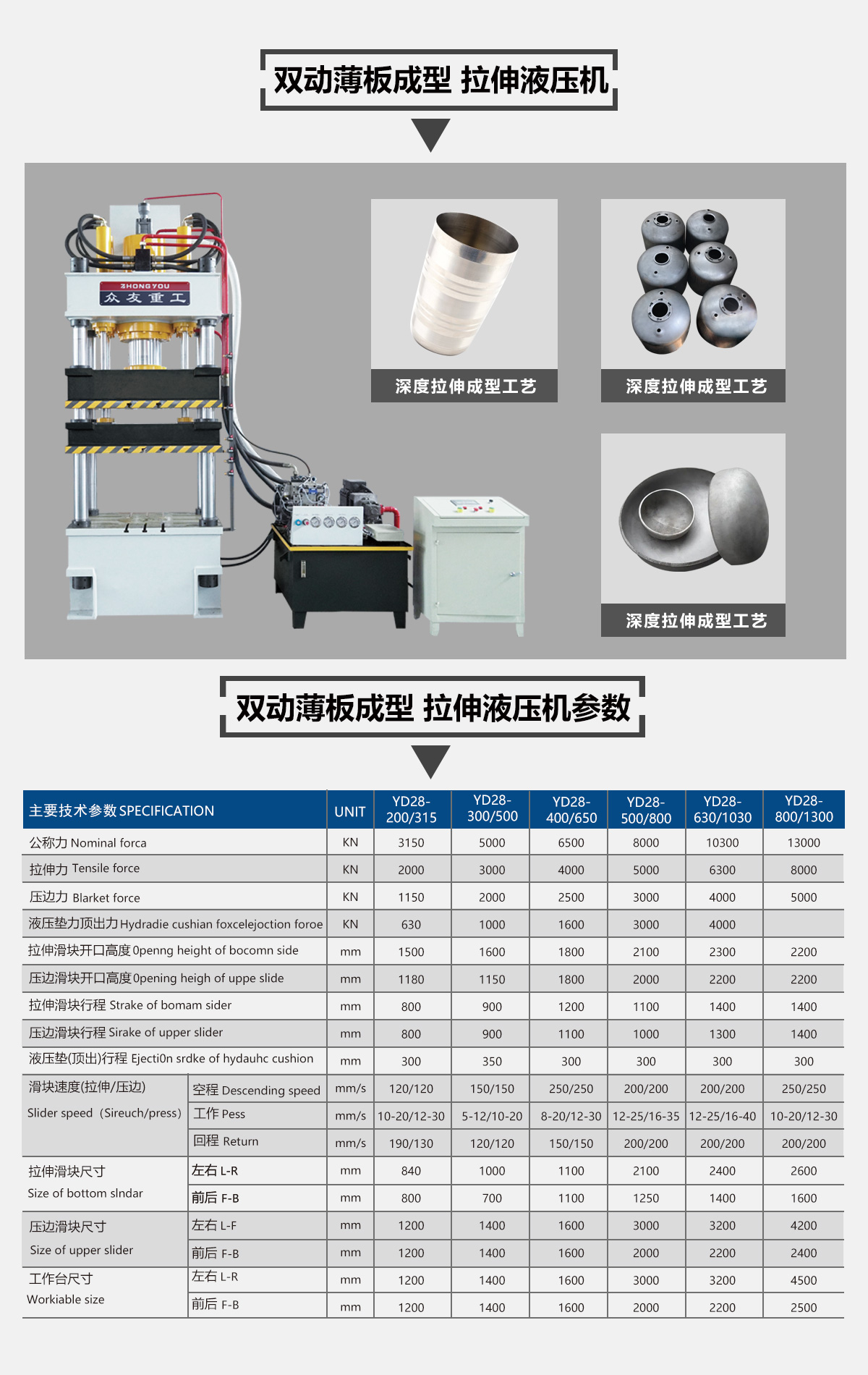

Double-acting stretching hydraulic press adopts advanced design concept and manufacturing technology, for a variety of tonnage selection, small precision parts and large industrial parts can have suitable models, high tonnage design, to ensure deep drawing, complex shape a molding, improve production efficiency and product quality.

Double-acting design, up and down moving beam independent control, to achieve precise positioning and synchronous stretching, reduce material waste, improve product accuracy.

It adopts high-quality hydraulic system and high-strength fuselage structure to ensure long-term stable operation and reduce failure rate. It is suitable for stretch forming of various metal materials such as stainless steel, aluminum, and copper to meet the needs of automobiles, home appliances, aerospace and other fields.

We provide a variety of models of double-acting stretching hydraulic press, including standard type, quick change model, etc., which are widely used in the stretching molding process of automobile covering parts, household appliance panels, building decoration materials, kitchen utensils and bathroom industries.

Body material selection of high quality alloy steel casting, after strict heat treatment, to ensure strength and toughness. The hydraulic system adopts internationally renowned brand hydraulic components to ensure efficient, stable and low-noise operation. The control system integrates PLC intelligent control and touch screen operation interface to realize automatic management such as parameter setting and fault diagnosis.

The hydraulic cylinder is made of high-strength alloy steel pipe, such as 42CrMo, the inner wall is precision machined and special wear-resistant treatment, which has good wear resistance and pressure resistance. The piston is made of high-strength aluminum alloy or high-quality carbon steel to ensure the hydraulic cylinder Efficient operation in high-pressure environment.

The die uses die steel with high hardness and high toughness, such as Cr12MoV, H13, etc. After quenching, tempering and other heat treatment processes, the die steel has a hardness of HRC58-62 and can withstand high pressure and friction in the double-acting stretching process. The automobile manufacturing field can produce automobile body covering parts, doors, engine covers and other parts. The aerospace field is used to process complex-shaped parts such as aircraft fuselage skin and engine covers, and the hardware industry, can make metal containers, tableware, lamps, etc.

The process flow of the double-acting stretching hydraulic press mainly covers the entire production process from material preparation, equipment debugging, stretch forming to product removal.

According to product requirements, select appropriate metal materials, such as stainless steel, aluminum, copper, etc., and use a shearing machine or punch to cut the bulk material into a size and shape suitable for stretch molding;

According to the shape and size of the product, select the appropriate mold and install it on the double-acting stretching hydraulic press, carry out no-load trial operation, and check whether the various functions of the equipment are normal. Before the stretching starts, the blank holder moving beam is lowered first, and the material edge is pressed on the mold to prevent the material edge from wrinkling during the stretching process. After the blank holder is completed, the stretching moving beam quickly approaches the workpiece, and then changes to slow stretching, after the stretching action is completed, the stretching beam shall be kept under a certain pressure for pressure holding delay to ensure that the material is fully shaped. After the pressure holding delay is completed, the stretching beam and the pressing beam shall be released and returned to the initial position respectively.

The company has an advanced R & D team and technical strength, focusing on the R & D and production of double-acting stretching hydraulic press, and has accumulated rich industry experience and technical reserves to provide customers with high-quality products and services.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

We Shandong Zhongyou heavy machinery and equipment adhering to the "quality first, customer first" principle, to provide customers with quality products and services