The plastic pallet hydraulic press makes the plastic material uniformly compressed in the mold through precise hydraulic control, and the density of the plastic pallet produced is uniform. This ensures that the strength of each part of the tray is consistent during use, and it is not easy to cause local damage. The advanced guide system and the precise mold match make the dimensional accuracy of the plastic tray very high. For example, the tolerance of the length, width and height of the pallet can be controlled within ± 1mm, ensuring that the pallet can be used stably and efficiently in the logistics and warehousing system.

Hydraulic presses of 500 - 800 tons are suitable for processing plastic pallets with medium bearing capacity. Such pallets are widely used in the industrial field. The material thickness is about 5-8mm. Hydraulic presses of 1000 tons and above are mainly used for manufacturing large and heavy plastic pallets, which can bear large cargo weight and the material thickness can exceed 8mm.

Due to the uniform and sufficient pressure during the pressing process, the plastic molecules are tightly combined, and the produced plastic pallets have good wear resistance, corrosion resistance and impact resistance, and have a long service life.

Plastic pallet hydraulic press commonly used four-column and frame hydraulic press, four-column structure is stable, high-precision guidance, suitable for the production of high-precision, small and medium-sized plastic pallets. For example, in the electronics, pharmaceutical and other industries, the dimensional accuracy and stability of the pallet are required to be higher; the frame structure has higher rigidity and carrying capacity, and is suitable for the production of large and heavy plastic pallets. Commonly used in chemical, machinery manufacturing and other industries.

Mold usually uses high hardness, high toughness die steel, such as Cr12MoV, H13 and so on. These die steel after quenching, tempering and other heat treatment processes, the hardness can reach HRC58-62, can withstand the plastic pallet pressing process of high temperature, high pressure and friction, prolong the service life of the mold.

In the logistics industry, pallets produced by plastic pallet hydraulic presses are used for loading, unloading, transportation and storage of goods to improve logistics efficiency; in the field of storage, plastic pallets of different specifications can be selected according to the characteristics and storage methods of the goods to facilitate the stacking and management of the goods; In industrial production, plastic pallets are used as turnover tools on the production line to carry raw materials, semi-finished products and finished products to ensure the continuity of the production process.

The body of the plastic pallet hydraulic press adopts high-strength alloy steel. After precision processing and heat treatment, it ensures that the structure is sturdy and durable, has a high degree of automation, reduces manual intervention, greatly improves production efficiency, adopts energy-saving motors and hydraulic systems, reduces energy consumption, meets green production standards, supports customized molds, and meets the production of pallets of various shapes, sizes and special needs.

The fuselage is made of high-strength alloy steel, through precision machining and heat treatment to ensure that the structure is strong and durable. The core components of the hydraulic system are selected from internationally renowned brands to ensure stable and reliable performance. Each process has undergone strict quality testing to ensure that the products meet the highest industry standards.

Shandong Zhongyou Heavy Industry invites you to visit our company and experience the excellent performance of plastic pallet hydraulic press. We will arrange professional engineers to introduce the product features to you in detail, and provide on-site test service, so that you can witness the efficient and accurate production process.

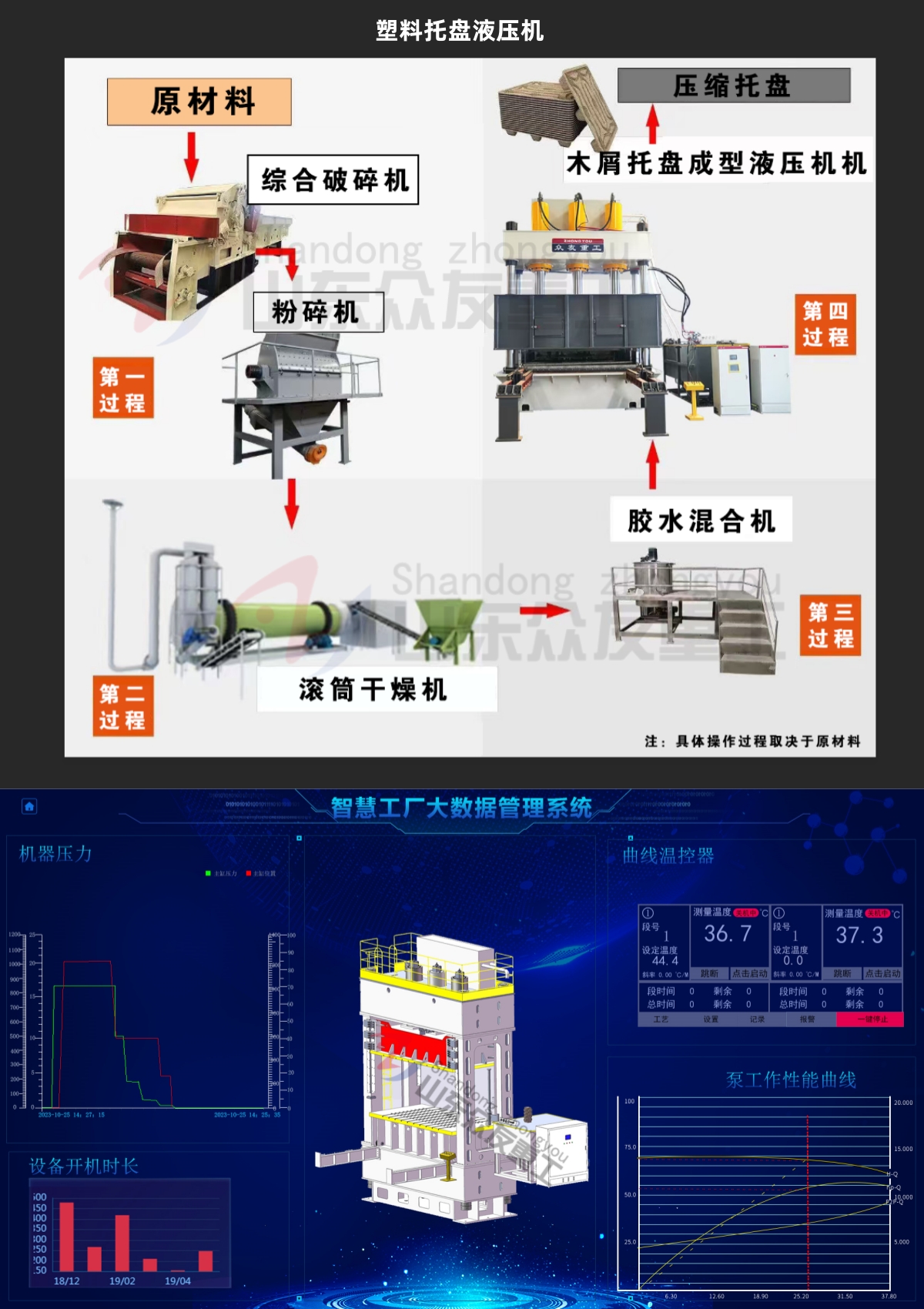

The process flow of the plastic tray hydraulic press mainly includes raw material preparation, extrusion molding, mold pressing, demoulding and post-processing.

The plastic powder, particles, fibers and other raw materials are preheated to shorten the molding cycle and dry the moisture in the plastic. According to the product requirements, the waste plastic is evenly mixed with other formula raw materials to form dough-like or suitable materials for extruder processing. The pretreated raw materials are put into the extruder, and the materials required for the upper and lower sheets are plasticized and quantitatively extruded through the screw, the upper and lower sheet materials are respectively laid on the upper and lower brackets with thermal insulation, and are ready to enter the mold for pressing.

Under the action of the hydraulic press, the plastic material is gradually solidified in the mold through the dual action of temperature and pressure. This process may include stages such as boosting and holding pressure to ensure the molding quality of the tray. During the pressing process, timely pressure relief and exhaust are carried out to eliminate air and excess gas in the mold and avoid defects such as bubbles. After the plastic parts are hardened and formed, the mold is opened, the tray is taken out, demoulding-cooling-trimming and de-stabbing-adding anti-skid pads and other steps.

Efficient, accurate and durable pallet production solutions

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

We sincerely invite you to visit our company and experience the excellent performance of plastic pallet hydraulic press. We will arrange professional engineers to introduce the product features to you in detail, and provide on-site test service, so that you can witness the efficient and accurate production process.