Composite manhole cover is a kind of manhole cover made of composite materials by high temperature processing of mold, which belongs to the hot pressing molding process of composite materials, and the main equipment required is composite materials.forming hydraulic press, mold, heating equipment (mold temperature machine or electric heating, oil heating), kneading machine, etc. The hydraulic machine is the main production equipment, hydraulic machine, including the host, hydraulic station and electric control cabinet three parts.

Composite manhole cover with low price, light weight, anti-theft, reduce urban noise and other advantages; in terms of anti-corrosion, composite resin manhole cover high-performance SMC sheet products, with acid, alkali, salt corrosion, no rust and other characteristics, suitable for use in -50 ℃ to 150 ℃ harsh environmental conditions.

Our equipment is suitable for the production of various types of resin manhole covers, whether it is a round manhole cover, a square manhole cover or other special shape manhole covers, it can easily complete the molding task. At the same time, it can also be customized according to the special requirements of customers to meet the individual needs of different customers.

Choosing our resin manhole cover molding hydraulic press is to choose high quality, high efficiency and high reliability. We will wholeheartedly provide you with high-quality products and services to help your business flourish.

The resin manhole cover forming hydraulic press adopts advanced hydraulic system to provide strong pressure and stable performance to ensure the quality of manhole cover forming. It is equipped with high-precision control system, which can realize automatic operation, improve production efficiency and reduce labor intensity. The body is welded with high-strength steel, which is sturdy and durable, and can withstand high pressure without deformation. The hydraulic components are all selected from well-known brands to ensure the reliability and service life of the equipment.

We provide a variety of specifications of resin manhole cover forming hydraulic presses to meet the needs of different customers. We have a professional after-sales service team to provide customers with timely and thoughtful technical support and maintenance services, and provide equipment installation and commissioning, training operators and other services to ensure Customers can use the equipment smoothly.

The fuselage is carefully welded by high-quality steel, the structure is strong and stable, and can withstand long-term high-strength working pressure without deformation. At the same time, we have carried out strict quality control on the welding process to ensure that each weld is firm and reliable.

The hydraulic components are selected from well-known brands at home and abroad, with reliable quality and stable performance. These high-quality components not only ensure the efficient operation of the equipment, but also greatly extend the service life of the equipment.

The special hydraulic press for resin manhole covers produced by Shandong Zhongyou Heavy Industry adopts a three-beam and four-column structure. The fuselage is welded with high-strength steel. The overall frame is firm and stable, and can withstand huge working pressure without deformation. In the welding process, we strictly follow the advanced welding process standards to ensure that every weld is firm and reliable, and provide a solid foundation for the long-term stable operation of the equipment.

Hydraulic pump: high quality hydraulic pump, high pressure, stable flow.

Hydraulic cylinder: using precision machining hydraulic cylinder, good sealing, hydraulic cylinder piston movement smoothly, can accurately transmit pressure, ensure the accuracy of the manhole cover molding.

Hydraulic valve: equipped with advanced hydraulic valve group, which can accurately control the flow direction, pressure and flow of hydraulic oil. It has the advantages of fast response speed and high control accuracy, and can quickly adjust the working state of the equipment according to different work requirements.

Oil pipes and joints: high-quality oil pipes and joints are used, which are firmly connected and have good sealing performance, and can withstand the impact of high-pressure hydraulic oil without damage or leakage.

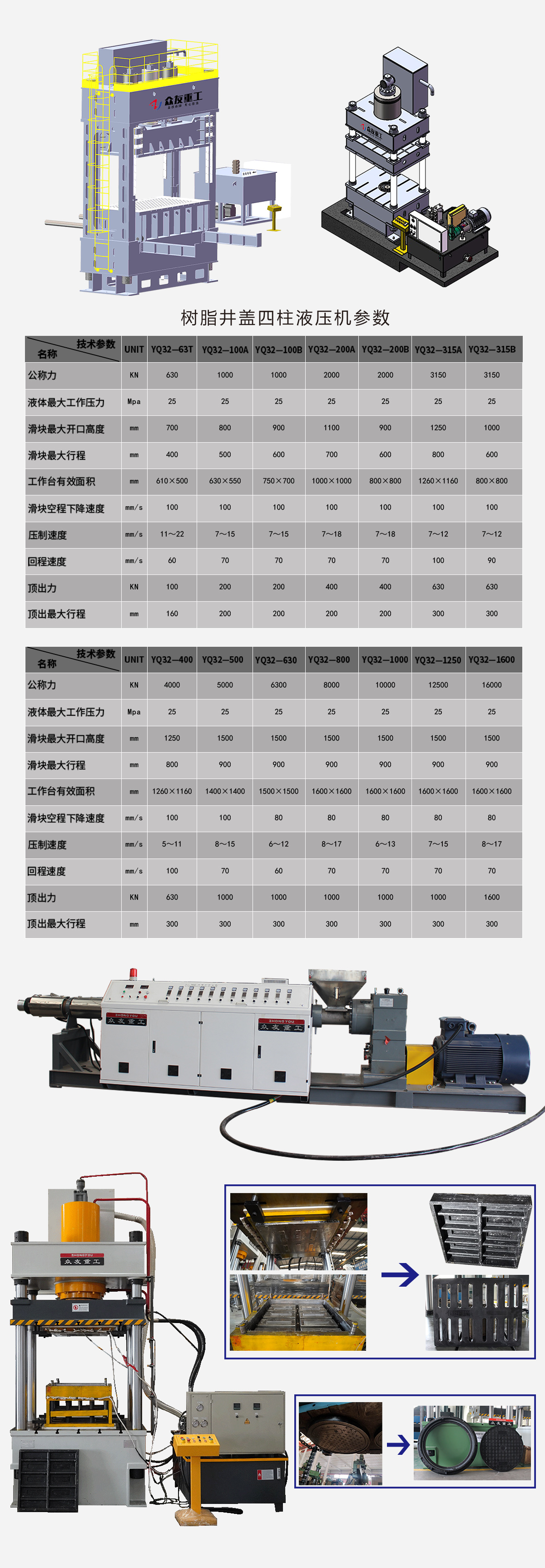

Special hydraulic presses for resin manhole covers are commonly available in five types of models: 315 tons, 400 tons, 500 tons, 630 tons and 1000 tons, which are divided into two types: one module and one module. The mold is electrically heated. The electrical cabinet is equipped with a mold temperature display and can be adjusted. The resin manhole cover forming hydraulic press has a variety of molds, has good guidance and density maintenance, reliable operation and convenient operation. Schneider is selected as the core electrical, which is safe and reliable, and the switchboard circuit is clear. When shipping, the electrical schematic diagram is carried with the random device, making it easier to use.

The hot pressing process of the resin manhole cover forming hydraulic press should adopt a composite hot pressing hydraulic press to meet the requirements of the pressing process. Equipment, curing time, pressure and speed all conform to the process characteristics of SMC/BMC materials. PLC control, convenient operation and adjustable working parameters; The resin manhole cover hydraulic press can be equipped with an in-mold core-pulling control system and a preset in-mold ejection control system, which can realize a series of actions such as rapid descent, sectional compaction, sectional deflation, work, pressure holding, slow mold opening, fast return, slow demoulding, fast ejection, fast ejection, fast return, etc, temperature can be multi-point control.

The company designs and produces two kinds of frame-type composite manhole cover hydraulic presses and four-column composite manhole cover hydraulic presses. According to the experience provided by the company for customers, the three-beam and four-column composite manhole cover hot-pressing hydraulic presses are usually used.

The resin manhole cover production line consists of a resin composite manhole cover molding hydraulic press, a mold, a mass mixer, etc. Shandong Woda Heavy Industry has rich experience in the production and service of resin composite manhole cover molding hydraulic press, and provides a full set of resin composite manhole cover production line plans free of charge. Welcome to inquire, communicate and cooperate ~

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Shandong Zhongyou Heavy Industry has a wealth of composite manhole cover forming hydraulic presses, with economical cost and wide application range. It can be controlled by PLC, delayed pressure holding and one-time forming.