carbon fiberforming hydraulic pressHigh-precision equipment for carbon fiber composite molding is suitable for the production of carbon fiber components in high-tech fields such as aerospace, automobiles, and sports equipment. Equipped with advanced hydraulic control system to ensure accurate molding under high temperature and high pressure. With fine-tuning function, it can realize fine pressure and temperature adjustment. The hydraulic press can provide uniform and stable pressure to ensure the high quality and consistency of carbon fiber parts.

The use of high-performance hydraulic system design, reduce energy consumption and improve production efficiency, with rapid heating and cooling function, shorten the production cycle, improve production capacity, accurate temperature control system can maintain a stable mold temperature, to ensure that carbon fiber composite materials in the molding process to achieve the best state, hydraulic design to ensure uniform distribution of pressure in the mold, effectively avoid the formation of bubbles or defects.

Equipped with touch screen control panel, easy and intuitive operation. Users can monitor and adjust the parameters in real time to improve the convenience of operation, with the function of automatic recording of production data, easy to track the production process and quality analysis.

Carbon fiber forming hydraulic press Carbon fiber composite hot pressing machine or carbon fiber board hot pressing machine is a device that uses hydraulic principle to press carbon fiber prepreg at high temperature and high pressure, so as to cure and form it. This kind of equipment is widely used in aerospace, automobile, sports equipment and other fields, and can produce carbon fiber products with high strength, high precision and light weight.

With fast movement speed and response ability, compared with the traditional mechanical molding equipment, higher production efficiency, through the hydraulic cylinder to provide uniform pressure, to ensure that the carbon fiber in the molding process by uniform pressure distribution, improve the quality of products.

Carbon fiber molding hydraulic press is widely used in aerospace, automobile, sports equipment and many other fields. In the field of aerospace, carbon fiber composite materials are widely used in aircraft wings, fuselage and other parts because of their light weight and high strength. In the automotive field, carbon fiber composite materials are more and more widely used, and the auto parts produced by carbon fiber forming hydraulic press have excellent mechanical properties and lightweight effect.

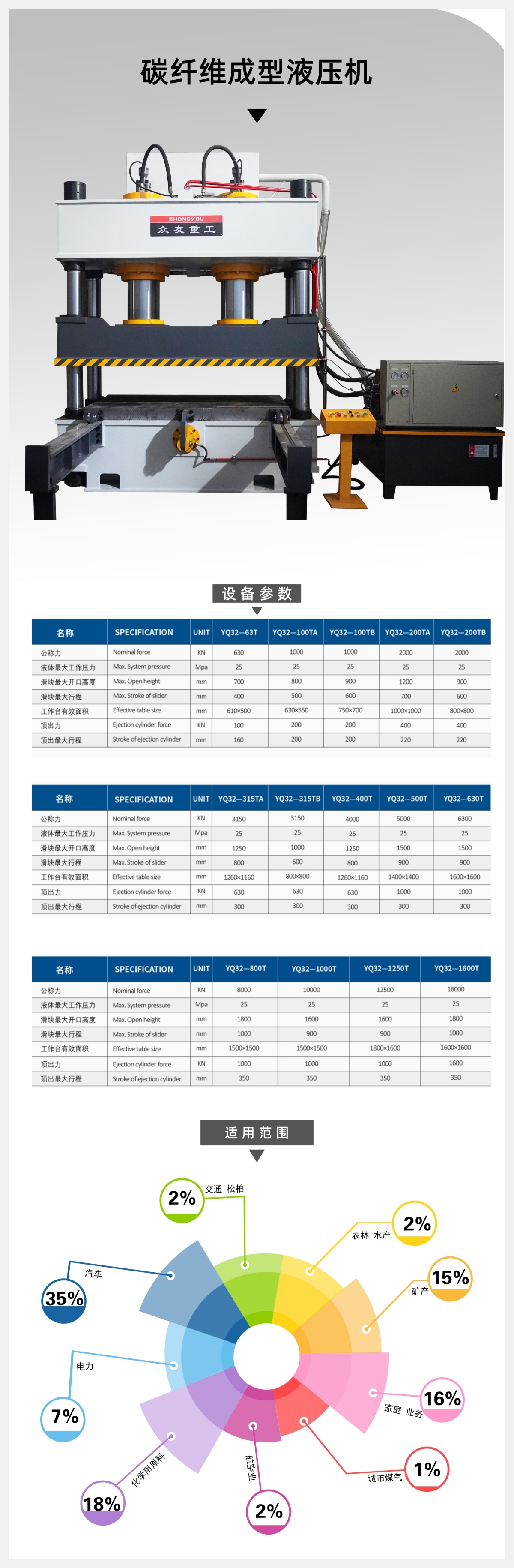

The carbon fiber forming hydraulic press is mainly composed of three parts: the fuselage, the hydraulic pump station and the electrical control system. The fuselage part is welded with high-quality steel plates, which has good rigidity and strength. The hydraulic pump station is responsible for providing hydraulic power and accurately controlling various actions of the hydraulic press through the electrical control system. The electrical control system adopts advanced numerical control technology, which can realize the setting and display of pressure, speed, stroke and other related parameters to ensure the stability and reliability of the molding process.

The carbon fiber molding hydraulic press can accurately control the parameters of the hydraulic system to achieve high-precision molding to meet the production of carbon fiber products with complex shapes and strict performance requirements. The heating element is generally installed inside or around the mold to be used for the mold and carbon fiber prepreg. Heating to promote the curing and molding of the resin. The heating element can be an electric heating wire, a heating tube or a heat radiation plate; the temperature control device is used to monitor and control the temperature of the mold to ensure that the temperature distribution is uniform and meets the process requirements. The temperature control device usually includes a temperature sensor, a temperature controller and an alarm system.

In the carbon fiber molding process, the carbon fiber prepreg is first laid flat between the upper and lower molds, and the mold is sealed. Then, the mold is placed on a hydraulic molding table, and high temperature and high pressure are applied by a hydraulic press to cure the resin and the prepreg in the mold. After a certain period of time, remove the carbon fiber products from the hot press, you can get a smooth surface, flat, high strength retention rate of the finished product.

The temperature control device mainly realizes the control of the mold temperature through temperature monitoring, signal processing, execution control, etc., using temperature sensors (such as thermocouples or thermal resistors) to monitor the temperature changes of the mold in real time, receiving electrical signals from the sensors, and processing and Analysis, preset the temperature curve or temperature range required by the molding process, and calculate the control signal by comparing the difference between the actual temperature and the set temperature. According to the control signal, the temperature control device will adjust the power output of the heating element (such as heating wire, heating tube), or start the cooling system (such as air cooling or water cooling device) to achieve the purpose of controlling the temperature of the mold. The temperature controller continuously monitors the temperature and adjusts the control signal, Forming a closed loop control system. This can ensure that the mold temperature is always kept within the set range, thereby improving the stability of the molding process and product quality.

The carbon fiber molding hydraulic press has high-precision pressure control, wide adjustable heating temperature, efficient automatic control system and flexible mold configuration to meet the requirements of different specifications and requirements of carbon fiber composite molding.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products