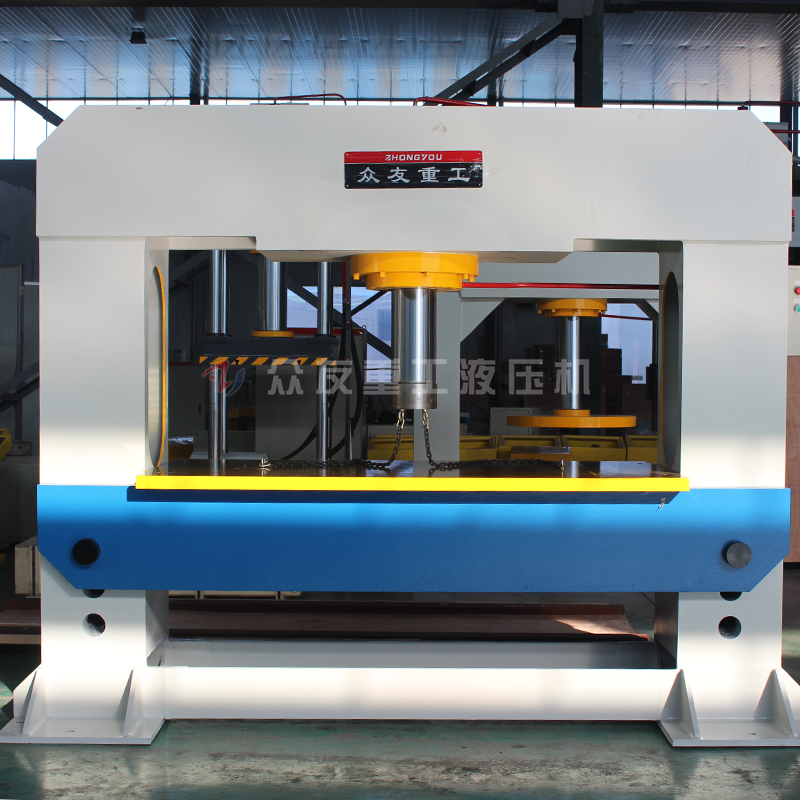

1. inframe type hydraulic pressAs we all know, the main cause of hydraulic machine vibration is the liquid stored in the working cylinder.A sudden release of greater energy. Therefore, the way to solve this problem is to try to reduce the storage amount of liquid elastic compression energy in the working cylinder.

2., the working cylinder and plunger of the frame hydraulic press using the tandem plunger hydraulic press are divided into upper and lower sections. When the idle stroke is downward, the upper and lower plungers and the moving beamdescend together; after contacting the workpiece,four-column hydraulic pressThe oil inlet and outlet of the upper cylinder are closed, but the upper chamber of the lower cylinder enters pressure oil and the lower chamber discharges oil, pushing the plunger and the moving beam to press down together.

When the material breaks and suddenly loses load, the plunger of the upper cylinder remains stationary, and only the plunger of the lower chamber may produce downward impact. However, since the lower cylinder only needs to meet the requirements of cutting off the materialThe plunger stroke does not need to be large, and the volume of the upper cavity of the lower cylinder can also be relatively small, so the elastic energy of the stored liquid is also relatively small, which correspondingly reduces the impact vibration

+86 13562463338

English

English

-

中文

中文

-

Spanish

Spanish

-

French

French

-

Arabic

Arabic

-

Korean

Korean

-

German

German

-

Russian

Russian

-

English

English