If you rely on the power of the hydraulic system in an industrial facility, you need to keep up with the maintenance of the hydraulic cylinder and prevent failures that cause downtime. This articleZhongyou Heavy IndustryBring six annual maintenance tasks to keep the hydraulic cylinders in good condition.

The best action you can take to keep up with maintenance is to establish a regular plan so that all your employees know and can help. Sometimes, it is difficult to remember to comply with annual maintenance tasks instead of regular maintenance tasks, because daily maintenance tasks are already completed in daily operations.

This article lists the six maintenance tasks you need to remember to perform each year to ensure its continuous operation and maximize the life of the hydraulic cylinder.

1. ensure bar quality:

One of the most important considerations in hydraulic cylinder operation is the condition of the cylinder rod. If the rod is bent, the load transfer may affect the operation of the cylinder and eventually cause failure. Other important considerations are rod diameter and rod strength.

Periodic inspections should include checking the finish of the rod and ensuring that excessive finish will not cause seal leakage problems.

2. check seals and valves:

Various seals and valves constitute the most important part of the hydraulic cylinder.

Checking the piston and piston rod seals ensures that leakage does not cause cylinder drift to reduce cylinder efficiency or cause failure. The holding valve is another important component. If it fails to operate properly, it may cause pollution problems.

3. to keep the liquid properly conditioned:

The hydraulic oil must be kept free of any contaminants and foreign matter. Do not introduce aerated fluid into the hydraulic cylinder system, as it may cause sound level problems.

As part of the adjustment of the hydraulic cylinder fluid, the filter system should be checked to ensure that it successfully prevents contamination and there is no danger of blockage.

It is conventional to replace the filters of hydraulic cylinders to prevent fluid contamination and clogging problems.

4. check the cylinder:

Over time, the hydraulic cylinder tube will begin to expand. This usually occurs when the cylinder wall is too thin or the pressure generated by the cylinder is higher than the pressure that the cylinder material can withstand. When the cylinder tube balloon is inflated, fluid may be allowed to pass through the seal and create various problems, including hydraulic fluid contamination.

5. rotary cylinder:

Regular rotation of the cylinder can prevent downtime. The facility shall have cylinder spares available for the rotation schedule. This will keep the cylinder fresh.

After removing the cylinder for rotation and inspection, the seal can be replaced as needed, and the hydraulic circuit can be inspected.

Any varnish found during the inspection indicates that the oil temperature is too high. This may be due to the quality or quantity of oil used. Hot oil can also be a symptom of another mechanical problem or oil leak.

6. inspection accessories:

The accessories of the hydraulic cylinder assembly need to be maintained to ensure that the hydraulic cylinder itself is working properly. These accessories include clevis, ball joint, bracket and rod eye.

Accessories will wear out over time and need to be repaired or replaced. If you need to use a clevis or pivot pin, you will notice the tilt and play between the joint and the cylinder and may cause misalignment. If this problem cannot be resolved as soon as possible, the entire hydraulic cylinder assembly may fail catastrophically.

Not only should the accessories be checked once a year, but also every time the cylinder is removed for maintenance, inspection or rotation.

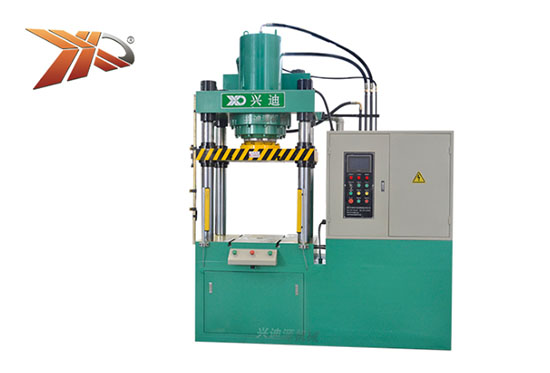

[Introduction to Zhongyou Heavy Industry]]

Zhongyou Heavy Industry (Xingdi Machinery) is a forging equipment manufacturer focusing on fluid pressure forming technology. Since its establishment in 2007, Zhongyou Heavy Industry has been committed to the technological innovation and product development of internal high pressure forming. The main products range from the production of ordinary hydraulic equipment, now developed to the production, research and development of domestic top fluid pressure forming technology forging equipment.

Zhongyou Heavy Industry is a provider of advanced lightweight forming technology. From product research and development, equipment production, mold development, program customization, to final delivery and value-added services, we provide customers with not only a hydraulic equipment, but a Complete set of intelligent manufacturing and forming solutions.