If you use hydraulic equipment, you may have realized that preventive maintenance is required. Equipment that cannot operate at optimal performance will cause waste and downtime risks, which in turn will cause loss of money and valuable time. Equipment will suffer from failures and loss of efficiency, but the practice of preventive maintenance will reduce or even eliminate such problems, which keeps your business running smoothly without interruption. Regular maintenance of equipment includes tasks such as lubrication, adjustment, repair and diagnosis. These tasks should be performed by professional licensed technicians with many years of experience serving customers in your industry. This articleZhongyou Heavy IndustryBring common preventive maintenance measures for hydraulic equipment.

1. Preventive and Passive Maintenance:

They say that an ounce of prevention is worth a pound of treatment, that preventive maintenance can catch subtle or advanced problems with a system before causing further damage or system failure, and that passive maintenance methods, on the other hand, defer maintenance until a potentially serious problem arises, leaving fewer options and a more expensive repair process. Most people know that preventive maintenance is more effective than reactive maintenance. Unfortunately, this does not mean that they integrate this beneficial maintenance plan into their business, which may expose them to extended downtime and expensive repairs.

According to the equipment manufacturer's instructions, preventive maintenance follows a predetermined schedule. An important advantage of planned maintenance is that it can be prepared in advance for offline equipment. Advancing the maintenance schedule a few months or even just a few weeks allows the staff to work within a few days of maintenance, which is much better than shutting down the intermediate production of a malfunctioning device. Preventive maintenance also reduces the number of potential accidents and violations of safety regulations that occur during normal use of the equipment.

The consequences of unexpected equipment failures can interrupt production and ultimately affect profits, so passive maintenance can be expensive and time-consuming, and sudden downtime often results in replacement parts, loss of revenue, and increased costs for idle employees.

Preventive maintenance of 2. hydraulic components-cylinders, pumps, motors and valves:

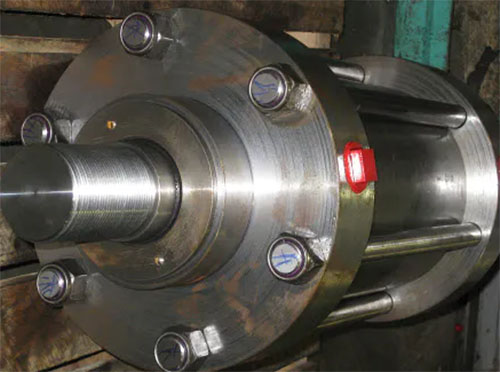

Preventive maintenance of hydraulic components usually includes equipment such as cylinders, pumps, motors, and valves. These components all have one thing in common: contaminants can seriously affect their performance and damage them. This is why hydraulic oil and filters must be maintained to achieve optimal efficiency and minimum wear.

Contamination is the main source of damage to hydraulic cylinders, so pollution control becomes an important issue in preventive maintenance. Preventing contamination involves tasks such as checking and replacing critical components (such as seals, vents, and filters). It also involves checking fluid cleanliness using the bottle sampling method or a portable particle counter.

Another important task of maintaining hydraulic components is regular inspection and replacement of oil. The oil is usually checked after about 50 hours of use and changed after about 500 hours, but it depends on the oil and system. Always refer to the manufacturer's recommendations. The oil temperature should be checked regularly during operation to find any overheating problems.

For pumps, maintenance includes visual inspection for external damage or wear, and more importantly, inspection for cavitation approximately every 50 hours (cavitation occurs when the pump does not receive enough liquid from the reservoir).

For motors, it is important to verify that they have started and operated at the appropriate RPM. In addition, the drive shaft of the motor should be checked regularly for signs of leakage.

The valve housing needs to be cleaned at least once a year (if the environment is dusty, it should be cleaned once more). The valve hardware should be checked regularly and confirmed that they can still be opened and closed. Visual inspection can reveal corrosion or mineral buildup on the casing, which may be a sign of a leak that needs to be addressed. Use the factory shutdown to pull the valve for inspection, cleaning and replacement as needed.

3. preventive maintenance should be carried out by professionals:

It seems easier and cheaper to hand over preventive maintenance responsibilities to an already on-the-job mechanic, but in the long run, choosing to use existing employees may become more expensive and time-consuming, just as existing employees know your equipment very well. In the same way, preventive maintenance is a professional field that requires experienced and hands-on experience.

Diagnosing hydraulic equipment problems can be a complex task for people who do not repair equipment on a daily basis. Our professional technicians are trained to use special equipment to diagnose problems before they occur.