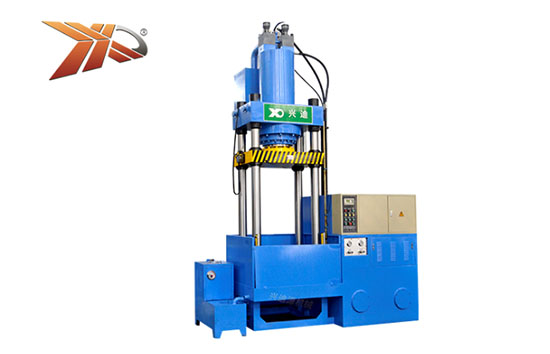

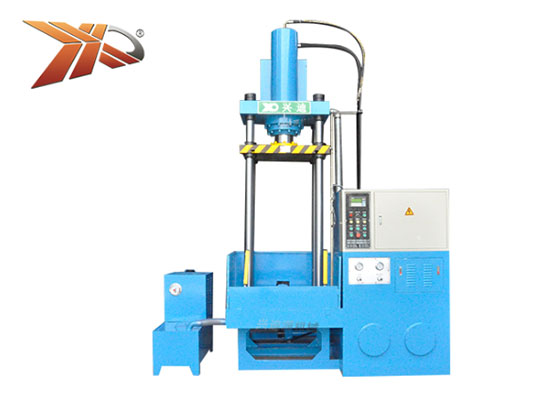

Shutdown is every machine building owner's nightmare, one of the main reasons why hydraulic systems start to fail and eventually fail is overheating, the good news is that you can avoid most of the causes of hydraulic oil overheating and take steps to keep it stable. Not sure why your hydraulic press is overheating?Zhongyou Heavy IndustryWhat is the correct temperature to bring the hydraulic oil? What is the cause of the overheating of the hydraulic press and the solution.

1. why is my hydraulic press overheating?

The root cause of overheating is that your hydraulic press generates heat faster than it dissipates. This hydraulic press cannot work effectively. The most common reason is a series of defects in the basic design of the hydraulic press.

The easiest way to prevent this from happening is to choose a press designed with heat protection and manufactured with high-quality parts. This press will last for several years. With correct maintenance, it can operate at a stable temperature.

What is the correct temperature of the hydraulic oil in the 2. press?

Whenever the hydraulic oil temperature exceeds 180 °F, your press is at risk. Temperatures within this range and above may damage the key compounds in the seal. Once damaged, it will cause leakage.

The higher the temperature and the longer the duration, the greater the damage that occurs in expensive presses. Its efficiency gradually decreases, thereby increasing the chance of overheating. At the same time, other parts of the equipment will also fail. In the end, the press was not available.

With continued overheating, the viscosity of the fluid decreases and it no longer has the ability to provide a barrier against heat and friction, which exacerbates the problems caused by overheating.

3. how to protect the hydraulic machine from overheating?

To prevent overheating, you need to keep the temperature of the hydraulic oil stable, which means that the heat of the fluid is dissipated faster during the heat generation of the hydraulic machine.

According to experts, you need a hydraulic system that can generate an input power of at least 100 kw of input power with an efficiency of 80%, which is enough to dissipate at least 20 kW of the thermal load.

Take a press with a 25 kw cooling system as an example. If the heating rate exceeds 25 kw or the cooling capacity drops below 25 kw, damage will begin.

Preventing overheating comes down to regular maintenance, and the most reliable way to ensure that the hydraulic oil in the press does not overheat is to keep the press in good repair, which means having competent employees to schedule scheduled maintenance, allowing time for workers to do thorough work, never delaying maintenance, and keeping an up-to-date record of all work done.

Make sure to change the oil according to the manufacturer's recommendations and your own experience. When the hydraulic oil is in good condition, your entire system will maintain higher efficiency and will not easily overheat.

As a result, the hydraulic press has a longer service life and can produce stable high-quality work. Due to hydraulic press damage and system failure, your downtime will be greatly reduced.