There are certain indicators that may be the right time to replace the hydraulic press, such as failure to reach the appropriate pressure level in time or abnormal sound, even if the press has been maintained at a very high level, will eventually suffer from failure due to simple natural wear. It is essential to be able to determine when the hydraulic press needs to be replaced so that your workshop does not suffer unnecessary downtime.

1. relief valve and pump:

A common problem with hydraulic presses is the presence of leaks. In many cases, small leaks may remain undetected until they become larger, causing greater damage to the press. Press efforts to reach the appropriate pressure level indicate that there may be leaks in or around the pump. The key to quickly identifying this problem is that if the problem is discovered early, replacing the pump can save the machine; however, if you wait too late, the damage that will be done to the machine is irreparable.

Pressure problems can also be caused by a faulty pressure relief valve. The valve that continuously releases the pressure too early will make it difficult for the press to reach the correct operating pressure. If the problem is found in time, it can be as simple as replacing the valve, but if it is not in time, it means that you must replace the entire machine. Most press technicians recommend that press operators be familiar with the sound and performance of the press under optimal operating conditions. In this way, they will be able to determine when the machine cannot run at full capacity, and then can immediately solve any minor problems.

the importance of 2. clean oil:

The importance of regular replacement of hydraulic oil cannot be underestimated. Hydraulic oil will lose its viscosity over time, and as the viscosity drops, the moving parts in the machine are more likely to wear. Once these parts are worn, they will affect the performance of the machine. This means that it needs to be replaced, otherwise it will eventually permanently damage the entire machine.

The oil dripping from the plunger clearly indicates that there is also an urgent problem. Regular inspection of oil is of great help in finding and repairing these types of problems, which can extend the service life of the hydraulic press.

3. electrical fault:

One aspect of the hydraulic machine maintenance process that is often overlooked is the maintenance of the electrical parts of the machine. The valve coil may wear, which means that it needs to be replaced. If it is not replaced in time, it may cause the machine to shut down during operation. The average life of the valve coil is about 3 million times.

The proper functioning of the electrical components of the machine is essential for the task of generating the proper pressure. When electrical components are not operating properly, it may cause performance degradation or machine shutdown. It is important to ensure that all electrical components are properly maintained to ensure the best performance of the machine and to ensure that there is no downtime.

4. crimping and hoses:

It is very important to ensure that all hydraulic hoses are properly maintained, otherwise the hydraulic press will encounter problems when maintaining proper pressure. Hydraulic oil leakage due to hose failure will also cause safety hazards. The hose should be checked regularly to ensure that the hose is not Ruptured or curled, the crimping of the hose will also have a negative impact on the pressure of the machine. It is important that the maintenance of the hydraulic hose is carried out by trained professionals.

5. to deal with the framework of the rupture:

The stability of the press frame is critical to the machine's ability to absorb process forces, creating precise and smooth operation. Even the smallest cracks in the frame can cause performance problems. Stress and fatigue cracks are usually small, but Will gradually deteriorate until the machine cannot operate normally. If you find a crack, you should immediately contact an expert who will know how to handle the situation, and you should probably also consider contacting a well-known manufacturer to buy a new hydraulic press at this time.

6. Replacement:

Knowing when it's time to replace your existing hydraulic press is critical, the longer the press you should replace is used, the lower the performance of the press and the worse the proficiency. These machines are responsible for creating many machines and mechanisms. Many important parts, this is why you cannot afford the failure of the hydraulic press. If your hydraulic press is not working properly, it may be time to change to a new hydraulic press.

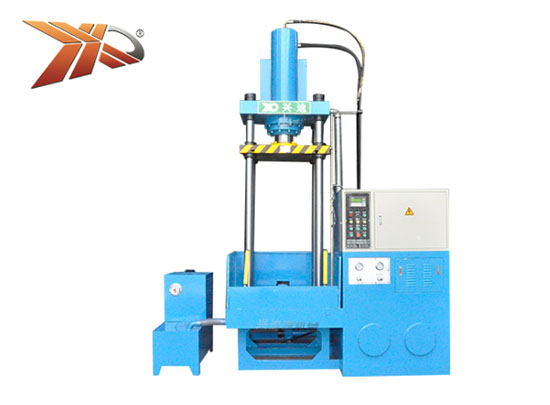

【Zhongyou Heavy Industrycharacteristics of rapid water expansion hydraulic press]]

Zhongyou Heavy Industry XD-Y63 Series Rapid Water Expansion Forming Hydraulic Equipment uses high-pressure liquid to form hollow parts or tube blanks outward, and gradually fits the mold cavity to form parts of specified shape and size. Liquid is injected into the vertical tube blank through the worktable, excess air is removed from the upper side, and the axial feed supplement is completed by the main cylinder. The structure is simple, the opening height is large, and the forming of parts with large axis length can be realized. Due to the large flow rate of the supercharger, the liquid is filled quickly, the forming speed is fast, and the forming efficiency is high.

This equipment is the implementation of fluid pressure forming process equipment, through the use of liquid (water, emulsion or oil) as the force transmission medium, with the fastest speed to make the hollow piece or tube expansion from the inside to the outside and fit the mold.