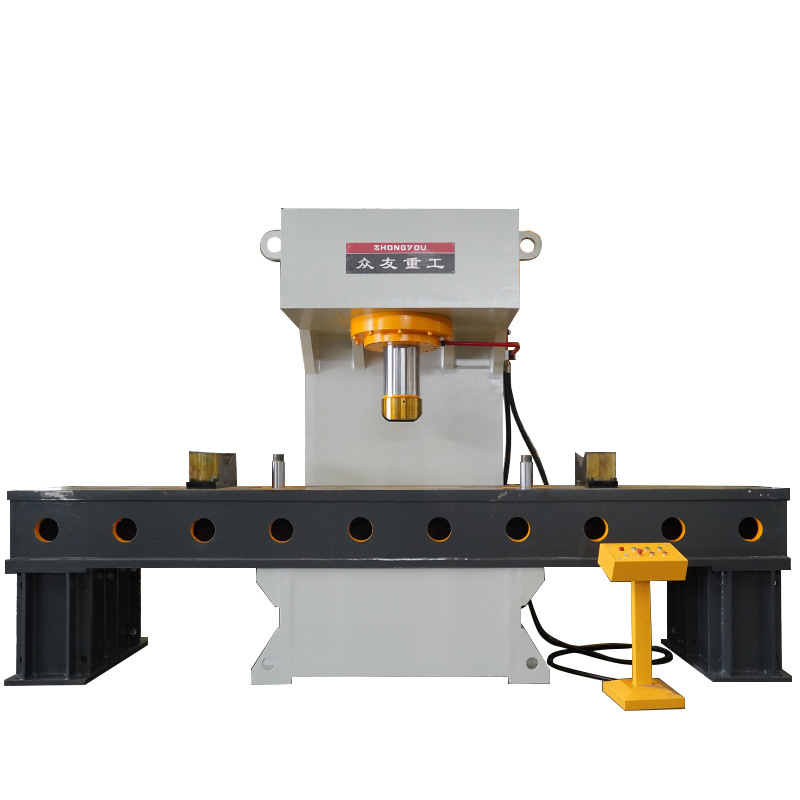

30 tons single-arm hydraulic press 30T single-column hydraulic press_C type blanking press

This model is a 30-ton single-arm hydraulic press. It is of C- type structure and is provided by Guangdong teaching laboratory. It adopts CO welding. The hydraulic series is located inside the fuselage. It has beautiful appearance and convenient operation. It can expand the working range and use the space on three sides to lengthen the stroke of the hydraulic cylinder.

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

Features of hydraulic press:

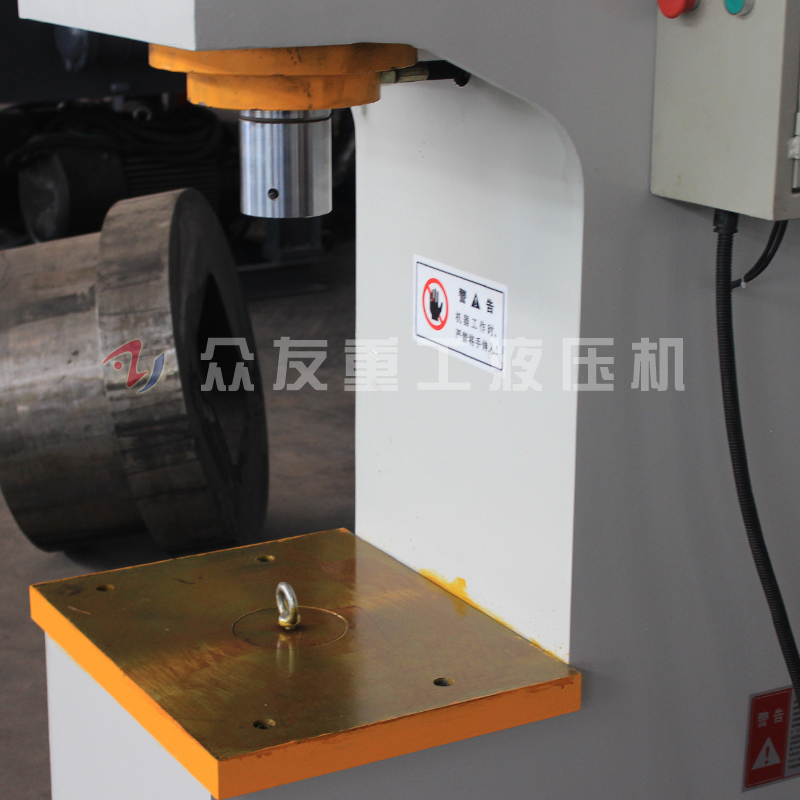

1. Computer optimization vertical machine C type structure design, good rigidity:

2. The slider is equipped with a guide column device, which improves the accuracy of the hydraulic press:

3. Independent hydraulic and electrical system, centralized control button:

4. Can realize constant pressure, fixed range two molding process, with pressure holding delay and automatic return performance:

5. It has two operation modes: adjustment and single circulation of both hands:

6. The working pressure and stroke can be adjusted within the specified range according to the process requirements.

7. The worktable is welded with high-quality steel plates to ensure reliability and durability

The company produced30 ton single column hydraulic pressThe fuselage is a C- shaped single-arm structure, using all-steel CO2 welding, and tempering and aging treatment after welding to ensure that the fuselage will never deform. The hydraulic system is located in the fuselage, beautiful appearance, convenient operation, can widen the working range, the use of three sides of the space to lengthen the hydraulic cylinder stroke (optional). This machine has an independent power mechanism and electrical system, using button centralized control, and is equipped with inching, semi-automatic working system. The working pressure, pressing speed and stroke range of this machine can be adjusted arbitrarily within the specified range as required. And can complete the fixed pressure forming and fixed range forming two process methods, in semi-automatic operation, the two process methods have pressure holding delay and automatic return action after pressing, our company can produce each tonnage according to user requirements.single column hydraulic press

| Parameter Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal force | KN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| effective stroke | mm | 260 | 260 | 280 | 320 | 360 | 400 | 400 | 500 | 500 |

| opening height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat body | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downward speed | mm/s | 16 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| return speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| workbench left and right | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Front and rear of the workbench | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| blanking hole diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

| Parameter Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal force | KN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| effective stroke | mm | 260 | 260 | 280 | 320 | 360 | 400 | 400 | 500 | 500 |

| opening height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat body | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downward speed | mm/s | 16 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| return speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| workbench left and right | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Front and rear of the workbench | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| blanking hole diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |