3000 tons facade embossing hydraulic press 300T steel plate press

The 3000-ton facade embossing hydraulic press is a large-scale hydraulic equipment customized for foreign customers and used for facade embossing. It has many characteristics and advantages and can meet the high requirements of different customers for facade decoration. The 3000-ton facade embossing hydraulic press, also known as the door panel embossing machine or the anti-theft door embossing machine, is a hydraulic model specially designed for embossing and beautifying the facade of modern anti-theft doors, steel and wooden doors, interior doors, etc. It can efficiently and accurately complete the embossing, embossing and other processes of the facade, making the facade pattern clear and beautiful, and enhancing the added value of the product. High pressure output: The equipment uses a hydraulic system to provide high pressure output, which can effectively process the texture to the surface of the material to ensure the depth and clarity of the texture. Precise control ability: equipped with hydraulic control system, can

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

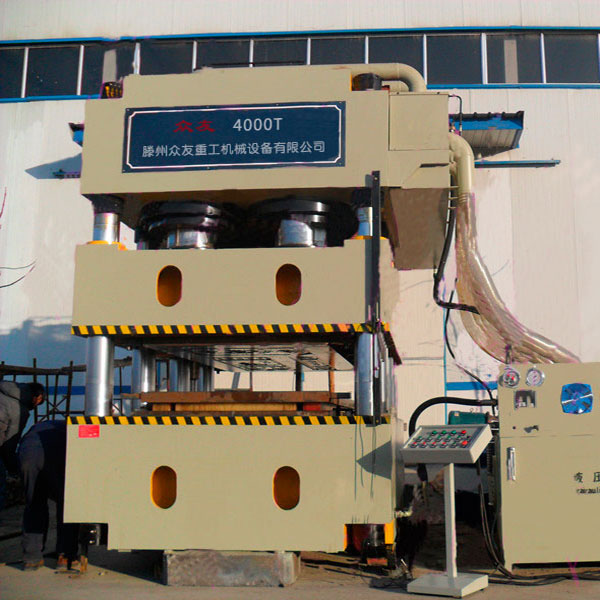

3000 tonsFacade embossing hydraulic pressIt is a large-scale hydraulic equipment customized for foreign customers and used for facade embossing process. It has many characteristics and advantages and can meet the high requirements of different customers for facade decoration.

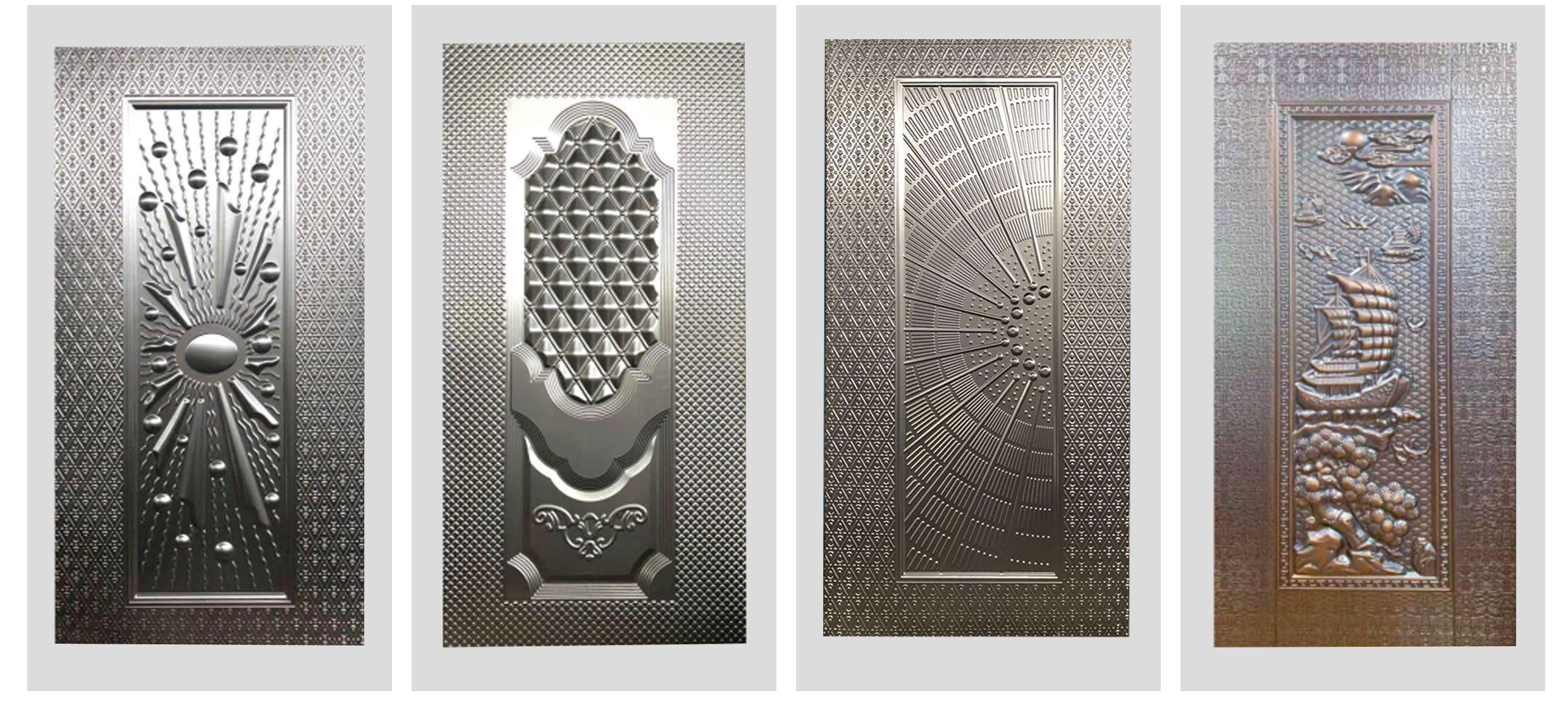

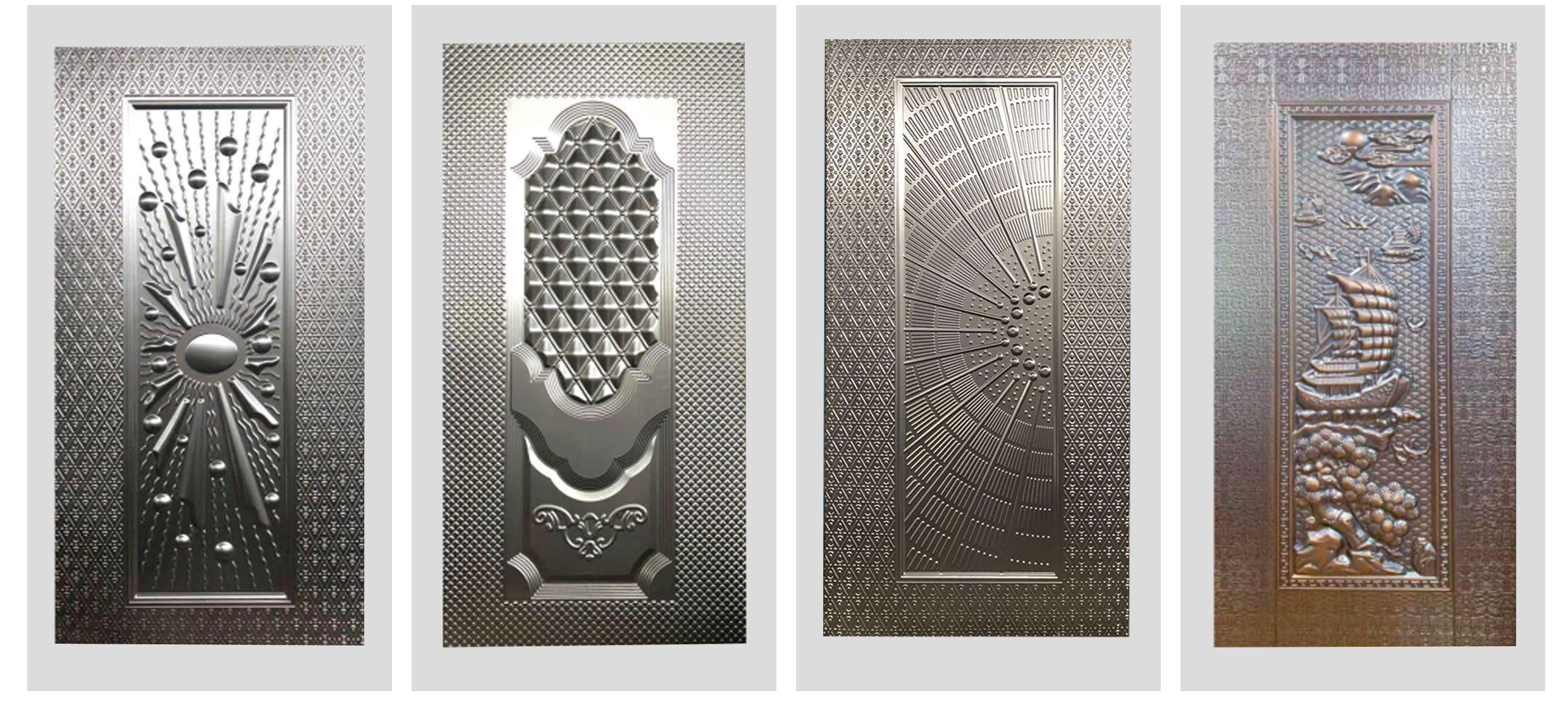

The 3000-ton facade embossing hydraulic press, also known as the door panel embossing machine or the anti-theft door embossing machine, is a hydraulic model specially designed for embossing and beautifying the facade of modern anti-theft doors, steel and wooden doors, interior doors, etc. It can efficiently and accurately complete the embossing, embossing and other processes of the facade, making the facade pattern clear and beautiful, and enhancing the added value of the product.

High pressure output: The equipment uses a hydraulic system to provide high pressure output, which can effectively process the texture to the surface of the material to ensure the depth and clarity of the texture.

Precise control ability: Equipped with hydraulic control system, it can accurately control pressure and speed to meet different material and texture requirements. The operator can adjust the parameters as needed to achieve precise control of the texture processing process.

Diversification: Suitable for different types of materials, such as metal plates, plastic plates, etc., and can process textures of various shapes, such as concave patterns, convex patterns, and complex patterns.

High efficiency processing: with high processing efficiency, can achieve rapid and continuous texture processing, greatly improve production efficiency, save labor costs.

Consistency and repeatability: it can ensure the consistency and repeatability of texture processing, ensure that each product has the same texture effect, and enhance the market competitiveness of products.

Safety and stability: Safety and stability are considered in the design and manufacturing process of the equipment, and it is equipped with multi-layer safety protection devices, such as emergency stop buttons, protective covers, etc., to ensure the safety of operators and equipment.

Pressure: 3000 tons

Pressing range: The thickness range of the pressed stainless steel plate is 0.4mm 2.0mm, the thickness of the aluminum plate is 0.8mm 5mm, and the maximum pressed product size is 2500mm × 1000mm.

Control system: classic PLC servo configuration, equipped with touch screen, can touch screen control and set the parameters.

Structure: On the basis of the continuation of the classic six-cylinder eight-column structure design, it is possible to integrate innovative design elements to enhance aesthetics and stability.

The 3000-ton facade embossing hydraulic press is widely used in the embossing of security doors, steel and wooden doors, interior doors, large iron doors, fire doors and other facade. With the continuous improvement of the market requirements for facade decoration, the equipment plays an increasingly important role in the fields of door and window manufacturing, architectural decoration and so on.

We ShandongZhongyou Heavy IndustryMachinery Co., Ltd. has rich production experience and professional technical team, can provide customized products and services according to customer needs. Customers can choose the right manufacturers to cooperate according to their own needs, and jointly create high-quality facade embossing products.

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process