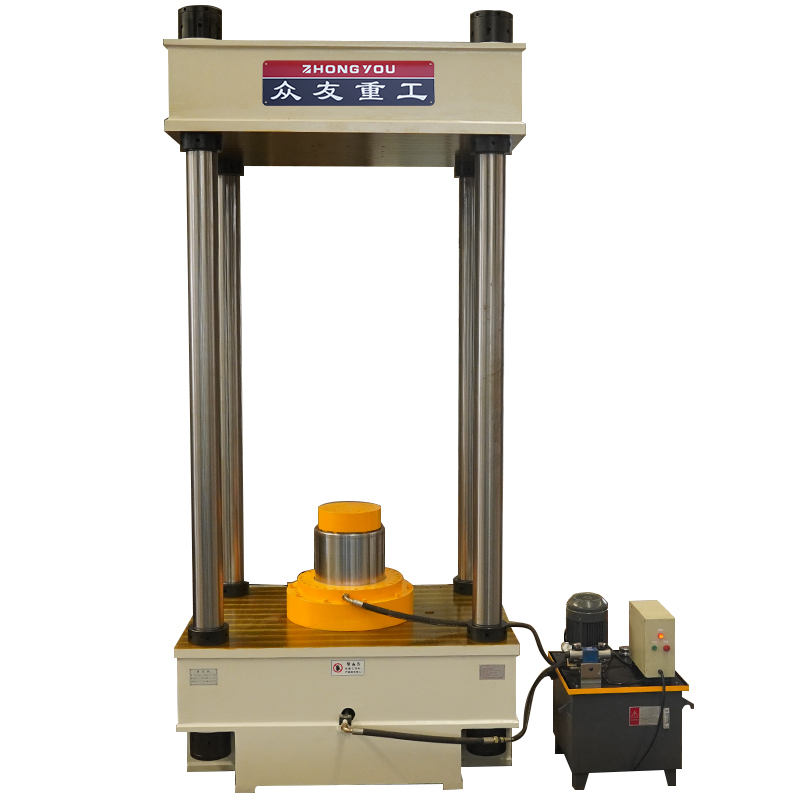

Full-automatic rubber block hydraulic press 120T multifunctional hydraulic press two-beam four-column press servo press

The working process of the rubber briquette hydraulic press usually includes the following steps: 1. blanking: put the rubber material to be processed into the briquette box. 2. Extrusion molding and long-term pressure holding: start the hydraulic press, push the pressure plate to squeeze the material through the expansion and contraction of the hydraulic cylinder, and keep it for a period of time to make it gradually fixed and formed. 3. The rubber block out of the cavity: after the rubber block is formed, the press block box is lifted out of the processing table by the lifting assembly, and the processed material is taken out through the blanking plate. The rubber briquette hydraulic press is mainly composed of the following parts: Processing table: a platform for placing materials and briquette processing. Block box: set in the groove on the processing table, used to hold the rubber material to be processed. Press plate: can be extended into the briquette box to squeeze the material. Hydraulic press

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

The working process of the rubber press usually includes the following steps:

1. Balling: Put the rubber material to be processed into the briquette box.

2. Extrusion molding and long time holding pressure: Start the hydraulic press, push the pressure plate to squeeze the material through the expansion and contraction of the hydraulic cylinder, and keep it for a period of time to make it gradually fixed and formed.

3. The rubber block is out of the cavity: After the rubber block is formed, the press block box is lifted out of the processing table by the lifting component, and the processed material is taken out through the blanking plate.

The rubber block hydraulic press is mainly composed of the following parts:

Processing table: A platform for placing materials and briquette processing.

briquette box: Set in the groove on the processing table to hold the rubber material to be processed.

Pressure plate: It can be extended into the briquette box to squeeze the material.

Hydraulic press: The key component that provides power to drive the pressure plate to move through the expansion and contraction of the hydraulic cylinder.

Bracket: Fixed on the top of the processing table, used to install the hydraulic press.

LIFT ASSEMBLY: Set on the bracket, used to lift the briquette box out of the processing table after the rubber is pressed, so as to facilitate the removal of processed materials.

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Suppression case

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Suppression case