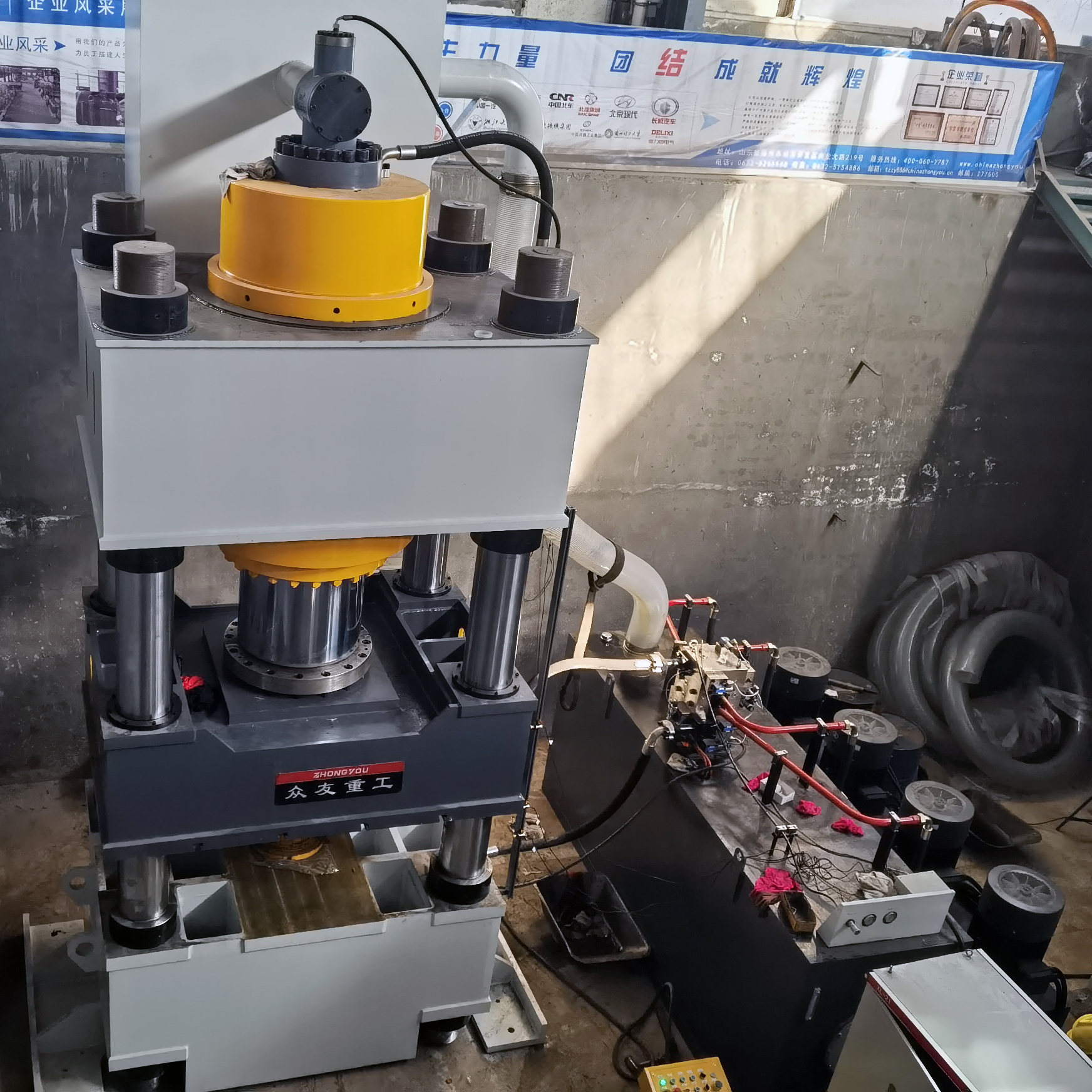

1200 ton hydraulic pressIt can process various high-strength materials, such as metal, plastic, rubber, etc., with high-precision control, good stability and strong adaptability.

The use of advanced hydraulic control systems and sensors can achieve precise control of pressure, stroke, speed and other parameters to ensure processing accuracy. The body structure is firm and welded with high-strength steel. It can withstand huge pressure without deformation. The system is stable and reliable, can work continuously for a long time, equipped with advanced electrical control systems and operation panels, and can change different molds and workbenches according to different processing requirements, realize a variety of processing processes, such as stamping, stretching, bending, extrusion, etc.

Metal processing industry can be used for sheet metal stamping, drawing, forging and other processes. For example, the manufacture of auto body parts, hardware tools, mechanical parts, etc., plastic products industry for plastic products compression molding, injection molding after demoulding, such as the production of plastic containers, plastic pipe fittings, plastic plates. Rubber products industry, rubber products can be vulcanized, molding and other processing. Such as the manufacture of tires, rubber seals, etc., can also be used in powder metallurgy, composite molding and other fields.

The 1200-ton hydraulic press transfers pressure in a closed pipeline through hydraulic oil to realize the processing and molding of workpieces. The working principle is based on Pascal's law. The pressure on the closed liquid can be transferred from the liquid to all directions with the same size. The pressure on the closed liquid can be transferred from the liquid to all directions with the same size.

The performance characteristics of the 1200-ton hydraulic press include high pressure, high precision, flexible action, strong reliability, and high degree of automation. It is used for forging various metal materials, such as steel, aluminum, copper, etc., and can manufacture shafts, discs, and special-shaped parts. Parts, blanking, stretching, bending and other processing of plates, production of auto parts, home appliance shells, and hardware products, used for molding of composite materials, such as SMC, BMC and other materials production, can also be used in refractory materials, rubber products processing and other fields.

As an important processing equipment, 1200-ton hydraulic press has broad market prospects in aerospace, automobile manufacturing, mechanical processing, building materials and other fields.

The hydraulic press is divided into single-column hydraulic press, double-column hydraulic press, four-column hydraulic press, frame hydraulic press, gantry hydraulic press, etc. It is suitable for different scenes, and our friends make customized technical solutions.

The hydraulic press mainly relies on the Pascal principle to work. The mechanical energy is converted into hydraulic energy through the hydraulic pump to produce high-pressure liquid. The process is as follows:

Prepare to check whether the parts of the hydraulic press are in good condition, including the body, hydraulic cylinder, hydraulic system, electrical control system, etc., install the required mold or tooling, and ensure that it is installed firmly, and adjust the working parameters of the hydraulic press according to the requirements of the processing technology. Such as pressure, stroke, speed, etc.

Feeding, place the workpiece to be processed on the workbench or in the mold to ensure the correct position of the workpiece.

Start the hydraulic press, press the start button, the hydraulic pump starts to work, the hydraulic oil is drawn from the oil tank, through the filter, hydraulic valve and other components, into the hydraulic cylinder.

Processing process, according to different processing technology requirements, the hydraulic press can achieve different action sequences and pressure changes

The material is discharged, the processed workpiece is taken out, and the quality inspection and subsequent treatment are carried out.

With the continuous progress and innovation of technology, the performance and function of hydraulic press will continue to improve, and the application field will continue to expand.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products