1500 ton hydraulic pressCommon three-beamfour-column hydraulic pressandframe type hydraulic pressThe hydraulic press is usually composed of a fuselage, a hydraulic system, an electrical control system and auxiliary components. The main technical parameters of the 1500-ton hydraulic press include the maximum system pressure, the maximum nominal pressure, the maximum opening, the slider stroke and the working table. For example, the technical parameters of the 1500-ton three-cylinder composite molded hydraulic press are: the maximum system pressure 25MPa, the maximum nominal pressure 15000kn.

The 500-ton hydraulic press can provide up to 1500 tons of pressing force, and has high accuracy and stability, which can meet the processing requirements of workpieces of different sizes and shapes. The hydraulic press is equipped with an advanced control system, which can control pressure, speed, time, etc. Parameters are adjusted and controlled to realize automated and intelligent production.

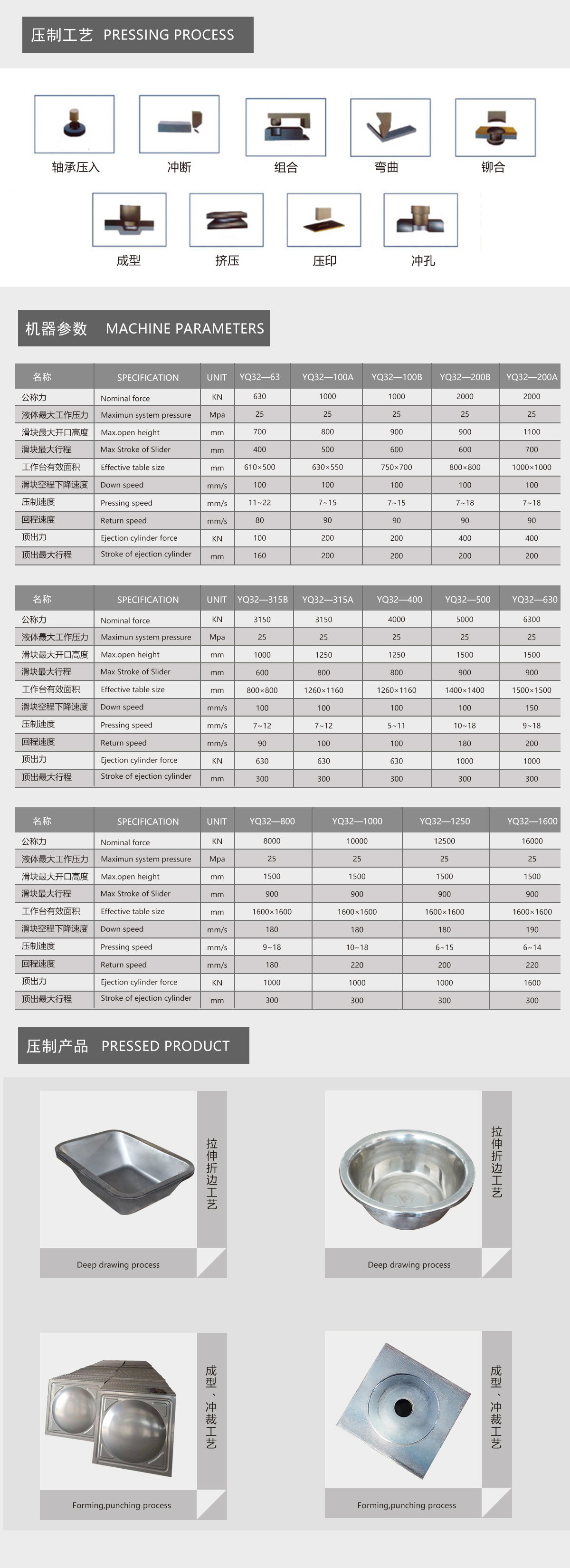

The hydraulic press adopts advanced hydraulic transmission technology and energy-saving design, with high work efficiency and low energy consumption. It is suitable for pressing, forging, stretching, bending and other processes of various metal materials, as well as the molding of non-metal materials.

The 1500-ton three-beam four-column hydraulic press has a stable structure and strong rigidity, which can ensure processing accuracy and quality. It is widely used in metal stamping, forging, stretching, bending and other process fields, such as automobile manufacturing, aerospace, mechanical processing and other industries. It can be used to manufacture various large parts, such as automobile covering parts, engine block, aircraft structural parts, etc.

The 1500-ton frame hydraulic press is composed of an integrally welded frame, which has higher rigidity and stability. The frame is generally made of high-strength steel. After precision processing and heat treatment, its strength and accuracy are ensured. The hydraulic system is installed inside the frame. The structure is compact and occupies a small space; it is mainly used in fields with high precision requirements and complex processing technology, such as electronics, electrical appliances, precision machinery and other industries. It can be used to manufacture high-precision parts, such as auto parts, precision molds, etc.

The hydraulic system adopts integrated cartridge valve control, which is sensitive and reliable, without leakage. It is equipped with a complete hydraulic safety circuit and a sliding block top dead center locking mechanism to ensure safe operation, realize automatic working cycle and automatic overload protection, and extend the components And the overall service life of the hydraulic press.

The 1500-ton three-beam and four-column structure means that the upper beam and the worktable are combined into a fixed frame through four columns, fastening nuts and adjusting nuts. The accuracy of the frame is adjusted by adjusting nuts, which has good strength, rigidity and accuracy retention. The worktable is large, equipped with T-shaped grooves, used for fastening and installing molds. The hydraulic system adopts frequency conversion servo control system, equipped with intelligent PLC control system, friendly operation interface and flexible programmable parameters, the operation is simple, and the slider adopts a four-column guide to ensure the precise positioning of the mold, so that the produced composite products have high dimensional accuracy and consistent shape.

The 1500-ton hydraulic press with frame structure consists of upper beam, sliding block, worktable, master cylinder, hydraulic pad, multi-top rod, hydraulic power system, electrical system and other components. The pressing cylinder tonnage of the hydraulic press is realized by a piston cylinder. The cylinder body is made of high-quality forged steel. The surface of the piston rod is quenched by intermediate frequency and has high hardness. The worktable and sliding block have T-shaped grooves, which are convenient for mold installation.

The process flow varies depending on the specific application scenario and the processing material, which is roughly summarized as the following steps:

Material preparation According to the processing requirements, prepare the right amount of raw materials, such as metal plates, composite plates, etc. The raw materials need to be pretreated, such as cutting, cleaning, drying, etc., to ensure their quality and processing performance.

Mold installation According to the shape and size of the processed product, select the appropriate mold.

In the pressing stage, the pretreated raw materials are put into the mold to ensure that the materials are evenly distributed and fill the mold cavity. For composite materials, attention should also be paid to the level and order of the materials.

Pressurized molding starts the hydraulic press, applies pressure to the mold through the hydraulic system, and maintains the pressure for a period of time after reaching the set pressure.

After the product is cured, start the demolding device of the hydraulic press, take the product out of the mold, perform necessary post-processing on the product, such as trimming, polishing, cleaning, etc., and perform quality inspection on the finished product.

We have advanced production equipment and testing methods, from raw material procurement to finished products, all have undergone strict quality testing and control

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

We are a professional manufacturer with many years of experience in the production of hydraulic presses, and have accumulated rich experience in the design, manufacture, installation and commissioning of 1500-ton hydraulic presses.