3000 tonsframe type hydraulic pressThe use of advanced control systems and precision mechanical structure, to achieve high-precision processing requirements, for a variety of processing methods, including cold pressing, hot pressing, die forging, forging, etc., to meet the needs of different industries and processes, improve production efficiency and flexibility.

The overall frame structure of the equipment and the application of high-strength materials make it have high rigidity and stability. The advanced hydraulic system and electrical control system also ensure the reliability and service life of the equipment. Modern hydraulic presses are usually equipped with Intelligent control systems, such as PLC control systems. These systems can achieve a key operation, remote monitoring and fault diagnosis and other functions to improve production efficiency and ease of operation.

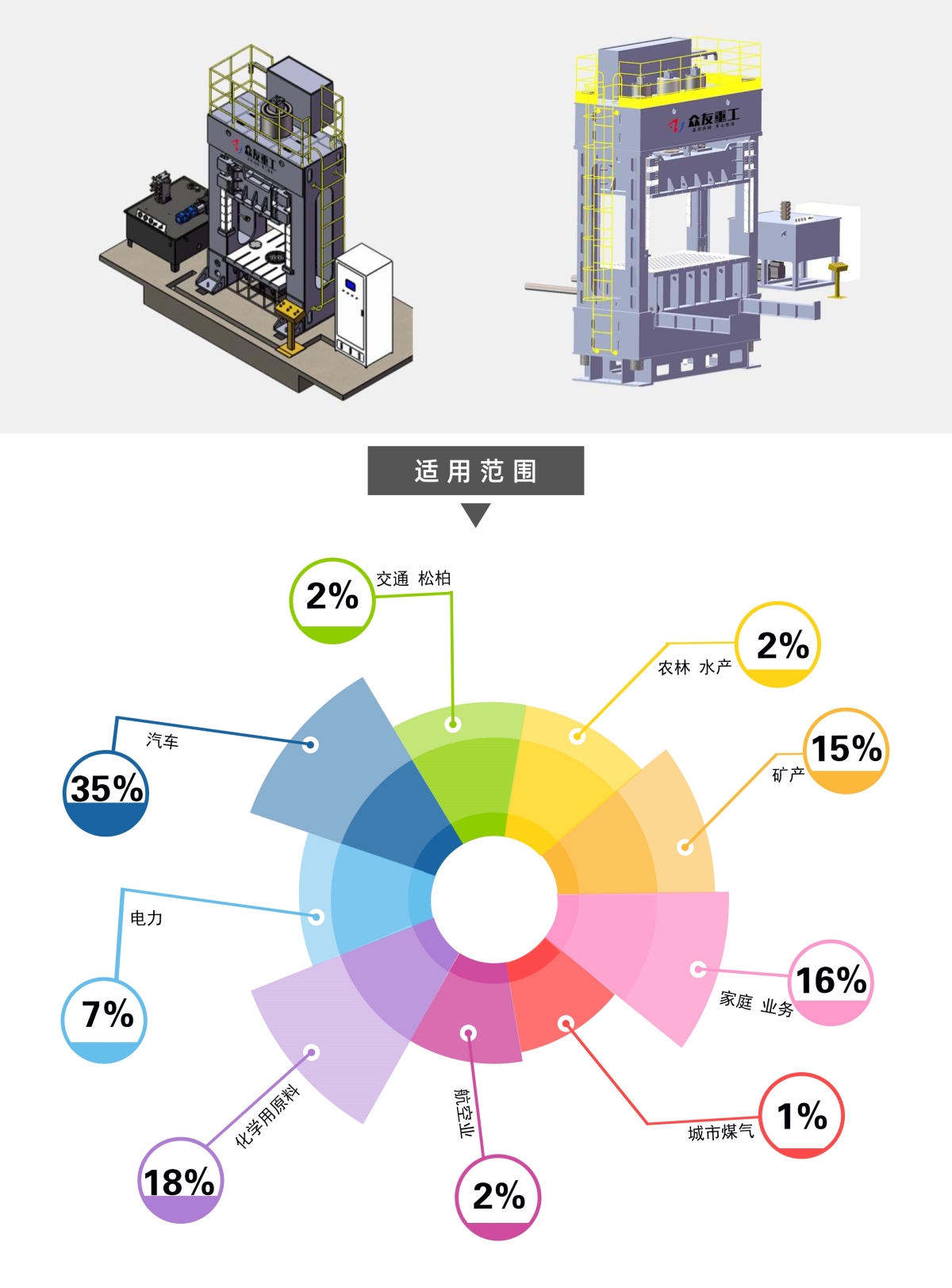

The 3000-ton frame hydraulic press is widely used in the metal processing industry and can be used to produce metal products such as auto parts, mechanical equipment parts, hardware tools, etc.

In the field of composite materials, the 3000-ton frame hydraulic press can be used for the molding of composite materials to produce composite products with excellent performance, such as building materials processing, environmental protection equipment manufacturing, etc. Heavy metal plates, large castings and composite materials can be pressed into shape, which can meet the demand for high-precision processing of large parts in heavy machinery manufacturing, aerospace and other fields.

The sturdy frame structure design ensures the stability of the equipment during operation. The advanced hydraulic system and high-precision parts make the equipment run reliably and reduce the probability of failure. It is equipped with multiple safety protection devices, such as overload protection, Limit protection, etc., equipped with high-precision guiding system, the movable beam has extremely high straightness and verticality during movement, to ensure that the processed parts have high dimensional accuracy and good surface quality, the intelligent control system can accurately control the pressure, stroke, speed and other parameters to achieve precise control of the processing process. The operator can adjust the parameters according to different processing requirements to meet the processing needs of various complex parts.

The equipment structure of the 3000-ton frame hydraulic press is the main structure of the whole equipment, which is welded by high-strength steel. The design of the frame is generally four-column or gantry type. The four-column frame is composed of four columns and upper and lower beams, while the gantry frame is similar to a large door frame structure. The strength and stability of the frame directly affect the processing accuracy and safety of the equipment.

The hydraulic pump is the power source of the hydraulic system. The control valve is used to control the pressure, flow and direction of the hydraulic system. The oil tank is used to store hydraulic oil. It also plays the role of heat dissipation and precipitation of impurities. The control system adopts advanced PLC control system or Industrial computer control system, sensors are used to detect various parameters of equipment, such as pressure, stroke, speed, etc. Safety protection devices include emergency stop buttons, limit switches, overload protection devices, etc.

The worktable is a platform for placing the workpiece. It is made of high-strength steel plate with sufficient bearing capacity and flatness. The slider is a movable part connected with the hydraulic cylinder. It moves up and down under the drive of the hydraulic system to press the workpiece.

The process flow of a 3000 ton frame hydraulic press usually involves multiple precise and orderly steps to ensure that the workpiece can be accurately pressed according to the design requirements.

According to the specific requirements of the workpiece, select the appropriate metal material, pretreat the selected material, and design the corresponding pressing mold according to the shape, size and accuracy requirements of the workpiece. Before starting the pressing, conduct a comprehensive inspection and debugging of the 3000-ton frame hydraulic press, place the pretreated material on the worktable of the mold, and perform precise positioning, start the hydraulic press, and make the movable beam under the push of the hydraulic cylinder Move downward, according to the material, shape and size of the workpiece, adjust the pressure, speed, stroke and other parameters during the pressing process, after the workpiece reaches the required shape and size, maintain a certain holding time to ensure that the stress inside the workpiece is released and stable. For processes that require hot pressing, cooling treatment is also required to reduce the temperature of the workpiece and increase its hardness and strength. After the pressing is completed, the workpiece is removed from the mold. Quality inspection of the pressed workpiece, including appearance inspection, size measurement, hardness test, etc., and subsequent processing of the workpiece as required, such as cutting, drilling, tapping, surface treatment, etc.

Zhongyou Heavy Industry adopts advanced hydraulic system and precision machining technology to ensure that the equipment can still maintain high precision and stability under high-speed operation

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

The frame structure of the hydraulic press is usually made of high-strength materials. After strict quality control and testing, the equipment can maintain stable performance and life when subjected to large tonnage pressure.