315 tonsframe type hydraulic pressIt is suitable for the processing of various large and heavy workpieces. It usually adopts an integral frame structure, which is composed of upper beam, lower beam, left and right columns, etc., with sufficient rigidity and strength. The slider guide adopts advanced guide rail design, which is convenient to adjust. High precision, good rigidity, strong anti-deflection load ability, suitable for various stamping processes such as deep drawing, bending, forming, blanking, flanging, etc, widely used in auto parts, household appliances, kitchen appliances and other fields.

Equipped with advanced hydraulic system, including hydraulic pump, hydraulic cylinder, hydraulic valve and other components. The hydraulic system adopts high-performance seals and hydraulic components to ensure the sealing and reliability of the system, and adopts advanced electrical control system, including PLC controller, touch screen, sensors and other components. The electrical control system has the characteristics of high degree of automation, convenient operation and strong reliability. The electrical control system can also realize the remote monitoring and fault diagnosis of the equipment, and improve the maintenance efficiency and safety of the equipment.

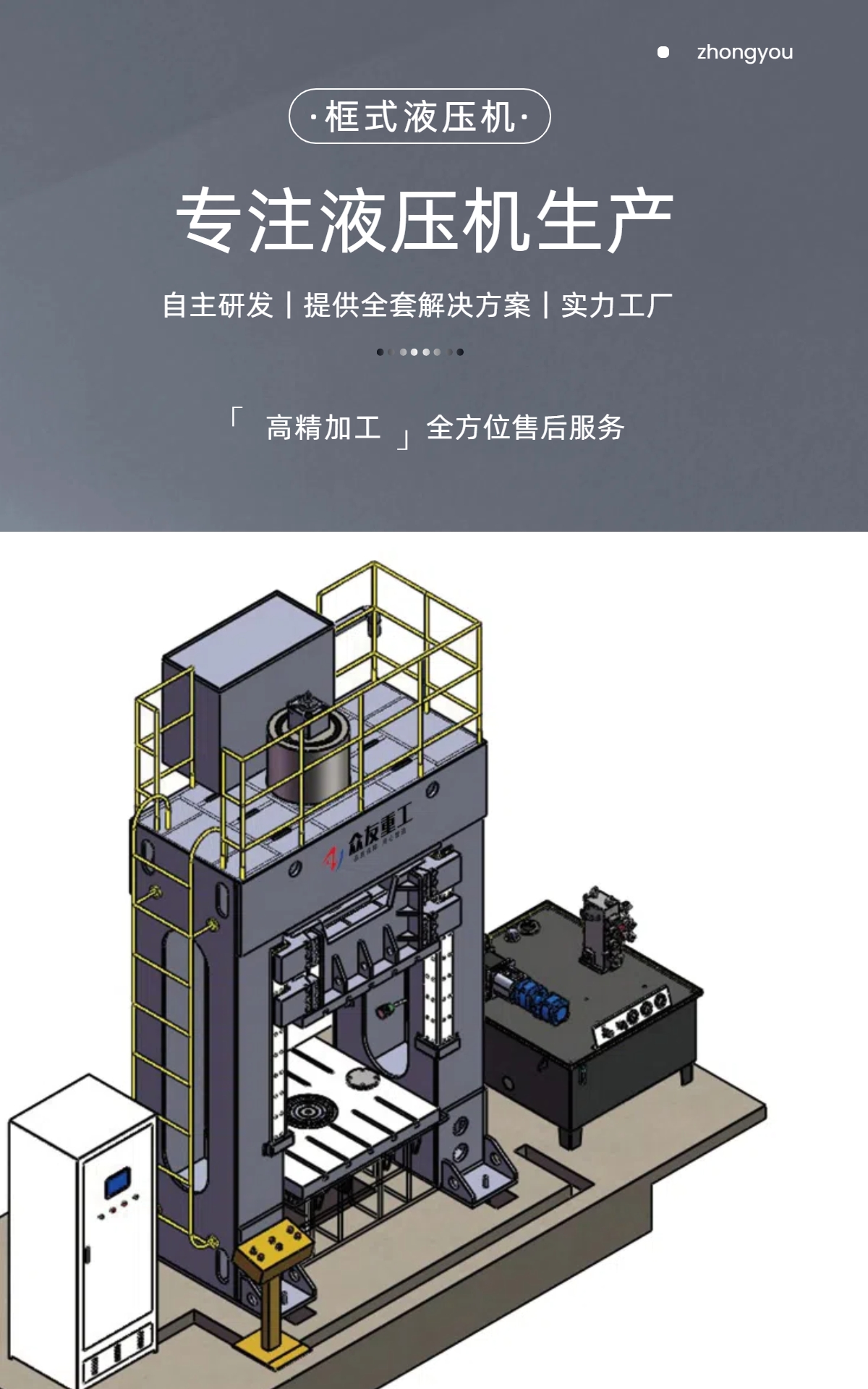

The 315-ton frame hydraulic press adopts a frame structure welded by all steel plates. This structure has extremely high rigidity and strength, and can withstand huge working pressure without deformation. Four corners and eight sides are designed with guide rails. The design of eight-sided guide rails improves accuracy.

The whole machine is designed into a modular structure according to different functional modes. This design makes disassembly and assembly simple and maintenance convenient. The modular design also makes the equipment customized and upgraded according to actual needs, which improves the flexibility and applicability of the equipment.

Equipped with an independent movable pumping station, the layout of the equipment is more flexible and can be adjusted according to the actual situation of the production site. The design of the independent pumping station also improves the reliability and stability of the equipment and reduces the failure rate.

The equipment adopts intelligent servo energy-saving system, which is energy-saving and low-noise. It meets the requirements of modern industry for energy-saving and environmental protection. It can be equipped with a variety of safety protection devices, such as photoelectric protection, emergency stop button, etc., to ensure the safety of operators.

The process flow of the 315 ton frame hydraulic press is as follows:

According to the shape and size of the product to be formed, select the appropriate raw materials, and carry out pretreatment, such as cutting, cleaning, etc., design and manufacture the mold according to the shape and size of the product, install the mold on the hydraulic press, and debug it to ensure that the mold is well matched with the hydraulic press.

Start the hydraulic press, put the raw materials into the mold, set the working pressure, working speed, stroke range and other parameters of the hydraulic press according to the product requirements, start the stamping process of the hydraulic press, and press the raw materials into the required shape and size.

After the stamping is completed, take out the product, inspect the product to ensure that the product quality meets the requirements, and carry out follow-up treatment on the product as needed, such as cooling, cutting, surface treatment, etc.

Zhongyou heavy industry has a professional after-sales service team, skilled, experienced, can quickly respond to your needs ~

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

The use of advanced hydraulic system design, to ensure stable pressure, accurate action, to provide a reliable guarantee for your production