ShandongZhongyou Heavy IndustryThe four-column hydraulic press of mechanical limited equipment adopts high-precision guiding mechanism to ensure high stability and accuracy in the process of mold installation, adjustment and pressing. It is equipped with high-performance hydraulic system, which can provide sufficient pressure output to meet the pressing requirements of various heavy materials, improve production efficiency, integrate advanced control system, support manual, semi-automatic and fully automatic operation modes, can be flexibly adjusted according to production requirements, has superior safety performance, and is equipped with multiple safety protection devices, such as overload protection, emergency stop button, etc., to ensure the safety of operators and equipment, reasonable structure design, easy to daily maintenance and maintenance.

Through the hydraulic system, the pressure can be accurately adjusted to meet the processing requirements of different materials and different processes. It has a precise stroke control function. The stroke distance can be set according to the processing requirements to achieve precise pressing. The modular design is adopted, and the mold replacement is simple and quick. Adapt to diversified production needs.

The four-column hydraulic press is widely used in automobile manufacturing, aerospace, hardware tools, home appliance manufacturing, building materials processing, metal products, plastic products and other fields.

The four-column hydraulic press adopts advanced hydraulic system, which can effectively improve work efficiency. The four-column structure design, the movable plate and the four guide pillars are highly precise, which ensures the stability and verticality of the equipment during operation, and can ensure the processing accuracy. It has independent power mechanism and electrical system, adopts plug-in hydraulic motor and other designs, can effectively reduce workshop noise, and is equipped with safety facilities such as photoelectric protection device and emergency stop button, ensure the safety of personnel and equipment during operation, and the force-bearing parts of the fuselage are optimized and firm without deformation.

The main cylinder and piston rod and other key components adopt high-quality forgings, which improves reliability and has a long service life. The surface of the column is quenched, plated with hard chromium and coated with oil seal film, which can improve wear resistance and prevent surface corrosion and scratches. High-quality hydraulic components are selected to ensure the durability of the hydraulic press. The oil tank is of steel plate welded structure, and the bottom is equipped with screw plugs for oil drain and sewage, which is convenient maintenance.

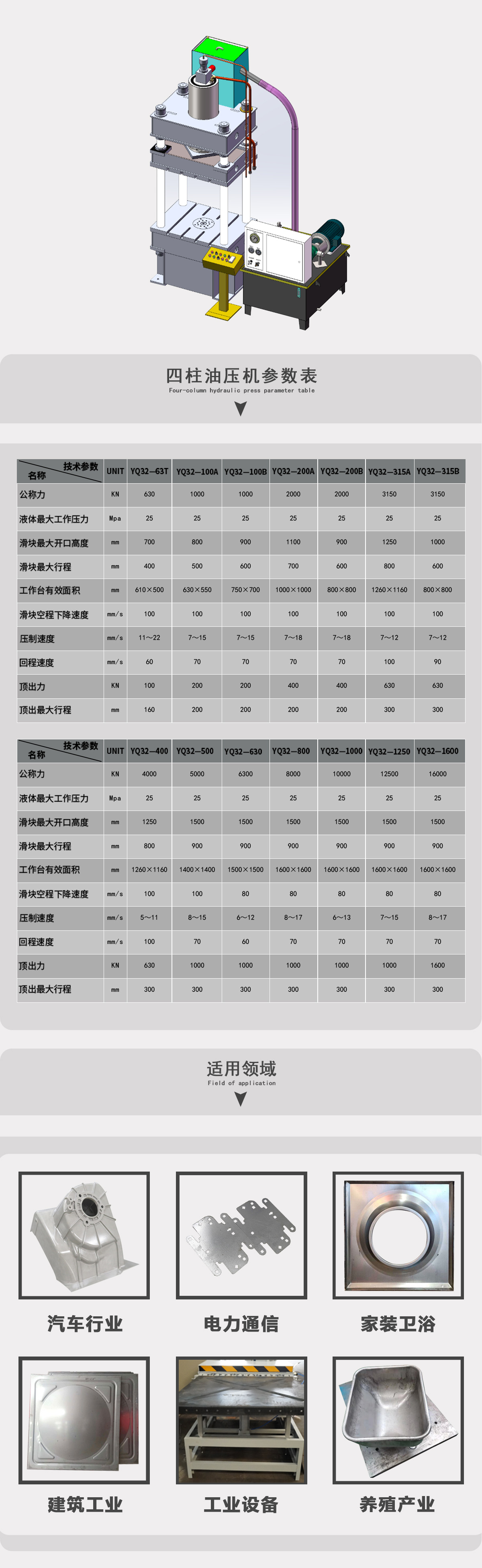

The specific performance and parameters of the four-column hydraulic press may vary depending on the model and specification. Customization is supported. The tonnage is 100 tons, 200 tons, 315 tons, 400 tons, 500 tons, 630 tons, 800 tons, 1000 tons, 1200 tons, 2000 tons, 3000 tons, etc.

Four-column hydraulic press, the fuselage structure adopts four-column type, which is composed of four columns, upper beam and lower beam. The use of high-quality alloy steel after precision processing and heat treatment, with high strength and good wear resistance, the upper and lower beams are generally cast steel or welded parts, to ensure the overall stability and rigidity of the equipment. The worktable is used to place the workpiece. The size and carrying capacity of the worktable are determined according to the specifications and uses of the equipment, which can meet the processing requirements of different workpieces. The slider is installed on four columns, and the mold or working head can be installed. The drive of the system realizes the processing operations such as pressing and stretching of the workpiece.

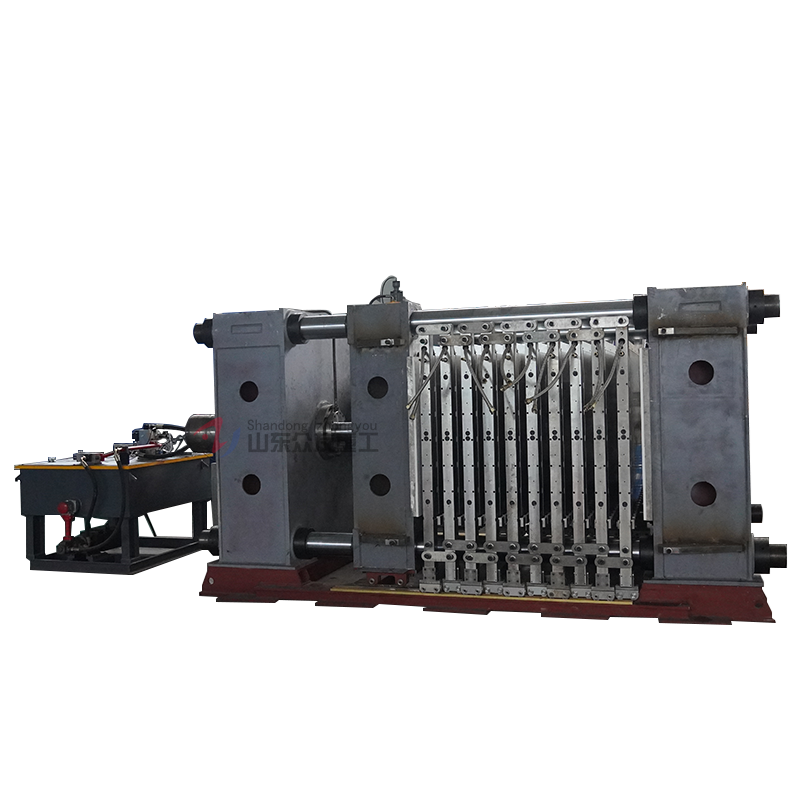

The hydraulic system consists of a hydraulic pump (gear pump, plunger pump, etc.), a hydraulic cylinder, a control valve group, and an oil tank. The power source of the hydraulic system.

The electrical control system is divided into control system hardware and control procedures, including PLC (programmable logic controller), touch screen, sensors, etc. According to the working requirements of the four-column hydraulic press, the corresponding control program is written. The electrical control system should have perfect safety protection functions, such as overvoltage protection, overload protection, limit protection, etc.

Before starting up, check whether the appearance of the equipment is in good condition, whether the connection of all parts is firm and whether there is any looseness. Whether the oil level is normal; Check whether the wiring of the electrical control system is firm; Check the mold installation; Clean up the sundries on the workbench.

Workpiece processing: Place the workpiece to be processed on the worktable and ensure that the workpiece position is correct. According to the processing requirements, set the relevant parameters on the control panel, such as pressing pressure, holding time, pressing speed, etc. Press the start button and the slider goes down to press the workpiece. During the pressing process, pay attention to observe the operation of the equipment, and immediately stop the machine for inspection if any abnormality is found. When the pressing reaches the set holding time, the slider automatically returns to complete a working cycle. Take out the processed workpiece and carry out quality inspection. If unqualified products are found, analyze the reasons in time and take corresponding measures to adjust.

After the processing is completed, switch the working mode of the equipment to the manual state, make the slider return to the top dead center position, turn off the hydraulic pump motor, cut off the power supply of the equipment, clean up the oil and debris on the surface of the equipment, and keep the equipment clean.

The four-column hydraulic press has high efficiency and energy saving, high precision, convenient operation, safety and reliability, good stability, wide application range and long service life. Shandong Zhongyou Heavy Industry Machinery Co., Ltd. has many years of hydraulic press production experience and is trustworthy.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Shandong Zhongyou Heavy Industry Machinery Equipment Co., Ltd. uses high-quality and durable raw materials for production to ensure the basic quality of hydraulic equipment, pay attention to every detail, conduct comprehensive and multi-level testing of finished products, and provide high-quality after-sales service to ensure that customers are in use No worries during the process.