Sagger hydraulic press is mainly used for sagger molding production, can be a variety of powder, granular materials pressed into a durable sagger, widely used in ceramics, metallurgy, electronics and other industries.

The four-beam and four-column structure of the sagger hydraulic press provides strong pressure through the hydraulic system, drives the slider down, and presses the material in the mold placed on the workbench. The hydraulic system consists of an oil pump, an oil cylinder, a control valve, etc., and realizes the precise movement of the slider by controlling the flow and pressure of the hydraulic oil. During the pressing process, the material is subjected to uniform pressure in the mold and gradually formed into a sagger shape.

Graphite crucible refers to graphite, refractory clay, silica, asphalt, tar and wax stone as raw materials fired into a kind of crucible. Graphite crucible is mainly used for smelting copper, brass, gold, silver, zinc and lead and other non-ferrous metals and their alloys. Graphite crucible has the advantages of high temperature resistance, strong thermal conductivity, good corrosion resistance, long service life, strong corrosion resistance to acidic and alkaline solutions, excellent chemical stability, and does not participate in any chemical reactions during the melting process. Moreover, the inner wall of the graphite crucible is smooth, and the molten metal liquid is not easy to leak and adhere to the inner wall of the crucible, so that the metal liquid has good fluidity and castability, suitable for a variety of different mold casting. The production of graphite crucible adopts compression molding process, that is, hydraulic press, etc.

The common tonnage of graphite crucible hydraulic press is 800 tons, 1000 tons, 1200 tons, 1500 tons, 2000 tons, 2500 tons, 3000 tons, etc. The mold can be replaced to press different shapes, such as square crucible, round crucible, nine-hole crucible, etc.

The sagger hydraulic press usually adopts a four-column or five-beam four-column structure. Based on Pascal's principle, that is, when the liquid transmits pressure in a closed container, the pressure phase everywhere, the hydraulic press presses the hydraulic oil into the hydraulic cylinder through the hydraulic pump, and pushes the piston And the pressure head connected with it makes a linear motion, so as to realize the suppression of the sagger raw materials. The entire pressing process is precisely controlled by the electrical control system to ensure the uniform transmission of the pressing force and the molding quality of the sagger.

Sagger hydraulic press is widely used in ceramics, refractory materials, metallurgy and other industries. In the ceramic industry, it is used to make ceramic saggers of various shapes; in the refractory industry, it is used to make refractory saggers for high-temperature furnaces; in the metallurgical industry, it can be used to make metal melt saggers. With the rise of new energy and other industries, the application scope of sagger hydraulic press is still expanding.

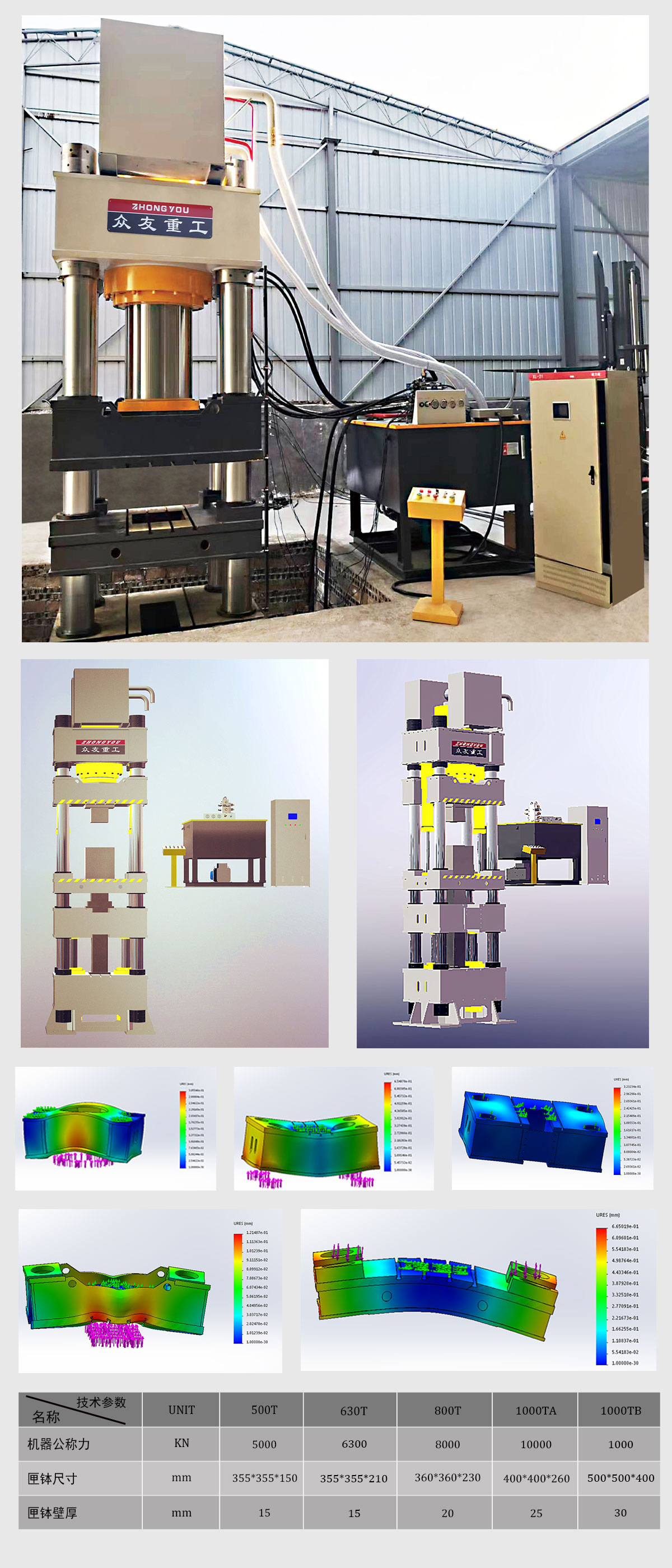

Graphite sagger crucible molding hydraulic machine host structure:

①. The main frame is of four-beam and four-column structure.

The upper beam is specially optimized to increase the rigidity of the frame and the bending resistance of the upper beam, and increase the stability of the machine.

③. The main cylinder is a double-acting piston cylinder, and the main cylinder is placed in the upper beam of the host to effectively reduce the total height of the press.

④. The movement guide of the upper movable beam is mainly guided by the main piston, and four tie rods are used as auxiliary guide rods, and the movement guide of the lower movable beam is mainly guided by four tie rods. ⑤. The piston adopts a guide belt made of special materials as the main direction, and the guide device composed of the upper movable beam and the press rod guides the press piston to ensure the movement accuracy of the press pressing cylinder parts.

⑥. The piston is rigidly connected with the upper movable beam, which can quickly and effectively transfer the pressure of the hydraulic oil acting on the piston to the upper mold core connected with the upper movable beam, and uniformly suppress the powder to improve the molding quality of the brick blank

According to customer requirements and product specifications, sagger hydraulic press carries out detailed drawing design, which includes the design of fuselage structure, hydraulic system, electrical control system and other parts. It processes the welded fuselage and uses numerical control boring and milling machine to process its surface, inner hole and T-groove. The main oil cylinder is a piston oil cylinder. The cylinder body is connected with the upper beam through a flange. The surface of the piston rod is quenched and ground to improve its wear resistance, the lock nut is made of 45# forged steel. The guide sleeve is equipped with lubricating grooves and dust rings. The columns are quenched and tempered and plated with hard chromium to improve surface accuracy and wear resistance. PLC programmable controllers, motors, sensors and other electrical components are adopted and assembled. The electrical control system is debugged and control programs are written to ensure accurate and reliable press operation.

The equipment of graphite crucible production line includes: thermal insulation double-shaft mixing barrel, paste measuring hopper, automatic conveying and loading device, graphite crucible mold, graphite crucible hydraulic press, etc. The specific process flow is as follows: graphite powder mixture-double-shaft mixing barrel mixing material mixing-paste measuring hopper measuring ingredients-automatic conveying loading and unloading device feeding into graphite crucible mold-starting graphite crucible hydraulic press-sliding block quickly descending-pressure holding delay according to the set exhaust number exhaust-sliding block fast return-stop-ejection cylinder will push out the compressed graphite crucible.

The double-station graphite crucible hydraulic press can freely set the number of exhaust, the 1st and 2nd stations work in turn, the pressing efficiency is high, the demoulding adopts a multi-stage hydraulic system, the demoulding is smooth, and the crucible density is guaranteed.

The hydraulic presses designed and produced by Shandong Zhongyou Heavy Industry have undergone strict control and inspection one by one from the parts to the finished products. Strong strength, advanced technology and equipment, perfect detection means, pragmatic work style, and excellent whole process management, build the excellent quality of the company's products

Shandong Zhongyou Heavy Industry has always been guided by the needs of customers and is committed to providing customers with high-quality, high-performance equipment and high-quality services. Graphite crucible hydraulic press is mainly used for graphite crucible/carbon crucible molding process. Various models are designed according to product specifications and sizes, and molding can be performed at one time. Double stations can be designed according to user needs to improve efficiency.