Is the hydraulic pump overheated during normal operation? The pump generates heat during operation, but specific heat parameters must be considered when designing. Overheating is an abnormal condition that can cause destructive problems, such as thinning of hydraulic oil, resulting in reduced lubrication and metal-to-metal contact of moving parts. And accelerate the wear and failure of the pump. Therefore, it is never a good idea to ignore a pump that exceeds its thermal parameters under normal load. There are many factors that lead to excessive heat accumulation, this articleZhongyou Heavy IndustryThe reason why the hydraulic pump becomes hot will be explained.

1) Incorrect viscosity of hydraulic oil

Hydraulic oil viscosity refers to the thickness or "resistance to toppling" of the hydraulic oil ". This is very important for the correct operation of the pump. The fluid not only transmits the power that moves the actuators and actuators. It can also lubricate internal components and dissipate heat from the system. Hydraulic oil is designed to operate within a specific temperature range. As it heats up, it becomes thinner and will eventually lose its ability to lubricate moving parts. Increased friction may cause the pump to heat up, and naturally increases wear when this occurs. On the other hand, hydraulic fluid that is too thick will flow less efficiently within the system, which can also lead to heat build-up.

2) Contamination of hydraulic oil

Fluids contaminated with dust, debris, water, and other impurities may cause heat accumulation in several ways. Clogged fluid filters, pipes and filters can cause unnecessary load on the pump, and even cause the pressure on the back of the filter to drop and cause cavitation.

3) Lack of oil

Low liquid levels can lead to insufficient flow to critical hydraulic components and moving parts. This is called lack of oil, just like driving without refueling, it will increase the friction between metal and metal and cause increased heat and wear. The hydraulic oil filter is blocked, and the improper design of the reservoir may also cause oil shortage.

4) Cavitation

Cavitation is the rapid formation and bursting of pores in a hydraulic fluid. When these pores collapse under pressure, they generate a lot of heat. In fact, the temperature at the time of implosion can be as high as 2700 degrees Celsius! Cavitation will not only damage the lubrication performance of the oil, but the excessive heat generated will also seriously damage the hydraulic pump and the entire system. Erodes hoses and seals, and causes metal parts to expand and wear.

5) Ventilation

This occurs when air enters the system through leaks at pump seals and pipe fittings, etc. What happens next in the hydraulic system? Compression! Air generates heat when it is compressed, and if it is not treated, it will naturally cause the temperature to rise. In extreme cases, it can also cause "hydraulic dieselization", in fact, compressed bubbles will explode in the same process that powers the diesel engine. This is not good and leads to degradation of the fluid and damage to the system components due to loss of lubrication and burning of the seals.

6) Normal wear

As the pump wears, the internal leakage or "slip" phenomenon will increase. Essentially, the fluid is able to pass through tightly fitted parts, which reduces the efficiency of the pump, but in addition, as this happens, the fluid moves from high pressure to low pressure without any mechanical work, because according to the laws of physics it cannot be destroyed, but converted into heat.

7) Troubleshoot pump problems and avoid unplanned pump maintenance

Excessive heat buildup is a symptom of a hydraulic pump problem, but it is far from the only sign that a problem may occur. You should also pay attention to other important warning signs. These include unusual noise, pressure problems and flow problems. Each of these symptoms provides clues to any potential pump problems that need to be addressed-so it's important to be familiar with all of them.

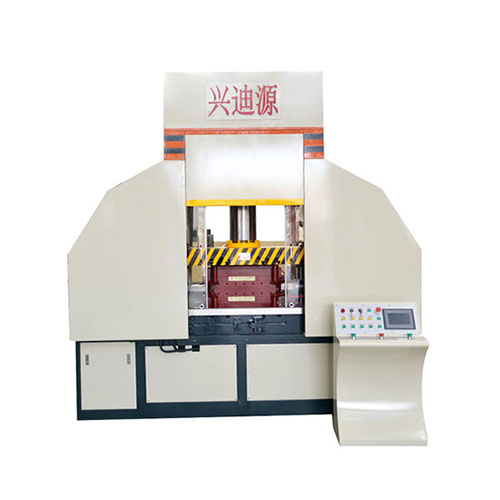

[Zhongyou Heavy Industry Hydraulic Machine Equipment Advantage]]

Zhongyou Heavy Industry takes fluid pressure forming technology as its core, and its leading products include: internal high pressure forming equipment, plate filling forming equipment, pipe parts hydroforming equipment, water expansion hydroforming equipment, multi-station connected hydraulic deep drawing equipment, four-column hydraulic press equipment, frame hydraulic press equipment, etc. It can design and manufacture special non-standard hydraulic equipment, non-standard oil cylinders, non-standard hydraulic systems and automatic transmission systems according to customer requirements.

The hydraulic press equipment produced by Zhongyou Heavy Industry is widely used in aerospace, nuclear power, petrochemical, auto parts, bicycle parts, hardware products, instrumentation, medical equipment, household appliances, household utensils, sanitary kitchenware and other manufacturing industries.