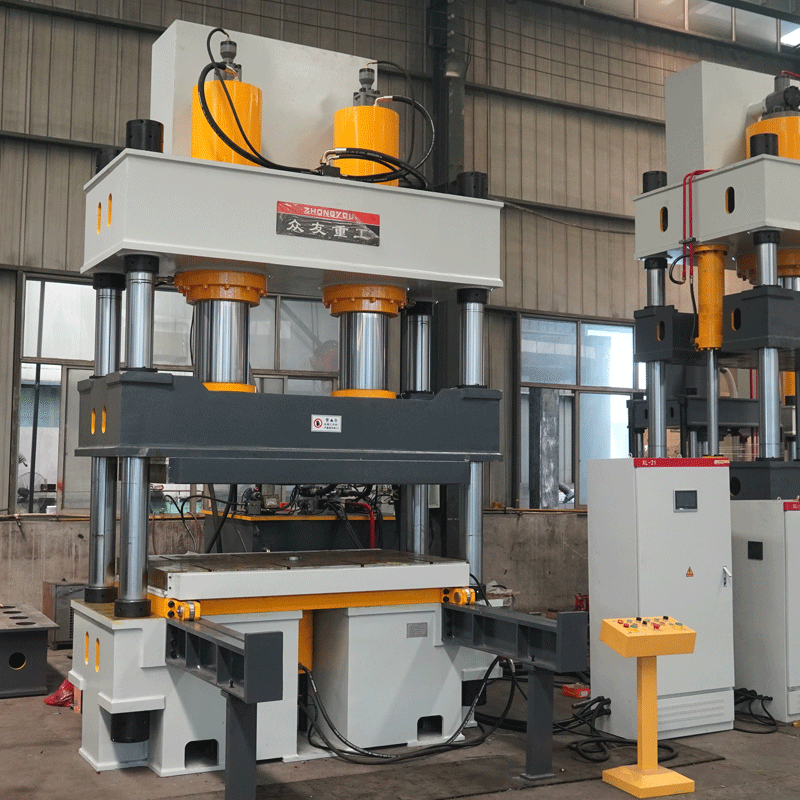

Sawdust pallet hydraulic press composite hot-press forming hydraulic press

Sawdust pallet hydraulic press is a kind of particle forming equipment specially designed for wood chips, straw, bamboo chips and other agricultural and forestry wastes. It is a special equipment for pressing loose wood chips into pallets or block products with high density and stable structure through high pressure compression.

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

Sawdust pallet hydraulic press: high-density, high-efficiency sawdust forming solution

In the field of biomass energy, agricultural packaging and logistics transportation, sawdust pallets have gradually become a popular choice to replace traditional plastic or wooden pallets because of their environmental protection, low cost and customizable characteristics. With its high pressure forming, high stability and intelligent operation, the sawdust pallet hydraulic press has become the core equipment of sawdust processing enterprises.

1 Technical highlights and core advantages

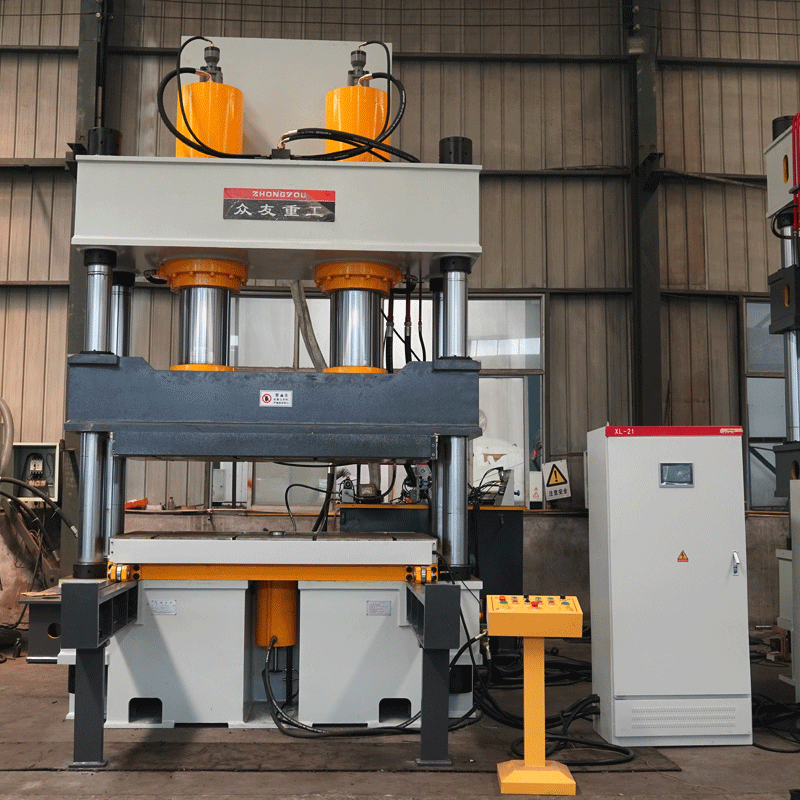

1. Ultra high pressure molding, density and strength of double excellent

High-pressure pressing: Using a double-column hydraulic system, the pressure is stable, ensuring the density of the sawdust pallet, the compressive strength is more than 1.5 tons, stacking resistance, moisture resistance and deformation resistance.

Uniform demoulding technology: equipped with multi-stage demoulding structure, to avoid the card material, the finished product pass rate is high.

2. Intelligent operation, a key control

PLC automatic control system: support a key start and stop, pressure adaptive adjustment, fault self-diagnosis, reduce manual intervention.

Real-time monitoring interface: display pressure, temperature, displacement data to ensure that the production process is transparent and controllable.

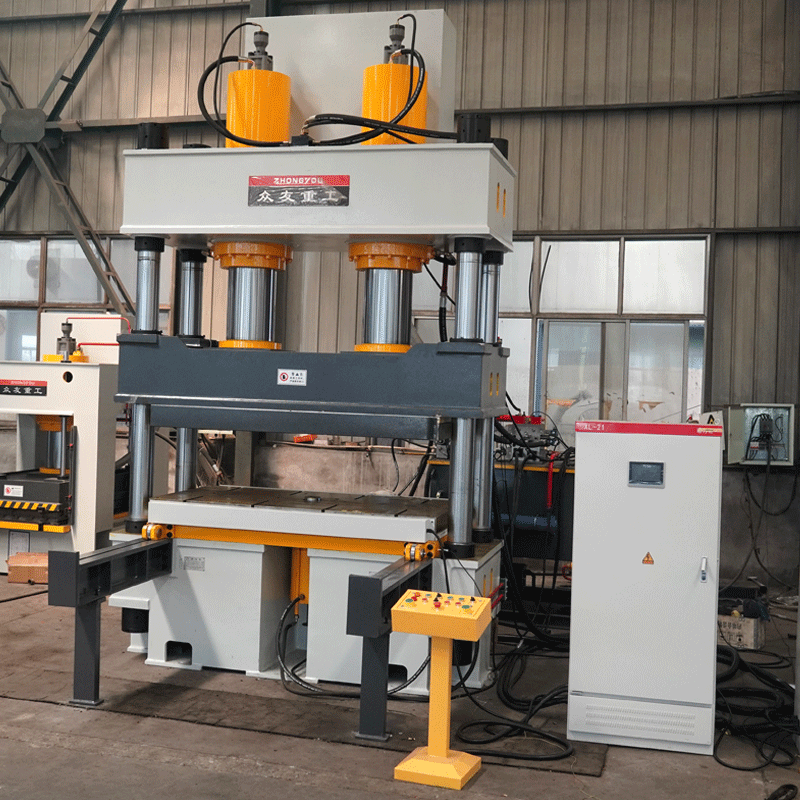

3. Energy saving and environmental protection, cost reduction and efficiency enhancement

Low energy consumption design: the hydraulic system adopts variable pump technology, which saves 30% energy compared with similar products, and the power consumption per ton is less than or equal to 8 degrees.

Closed structure: no dust overflow in the production process, in line with environmental protection emission standards.

4. Strong durability and convenient maintenance

Body material: the overall use of thick Q345 steel plate welding, the key parts of the annealing treatment, anti fatigue life.

Die hard chrome plating process: die surface hardness ≥ HRC60, high wear resistance.

2 Application Scenarios

Biomass energy industry: Pressed sawdust pallets are used for biomass pellet fuel storage and transportation, reducing transportation costs by more than 30%.

Organic fertilizer production: as a pre-pressure molding equipment before organic fertilizer granulation, improve the efficiency of subsequent granulation.

Agriculture and logistics: customized production of moisture-proof pallets for use in scenarios such as mushroom bar packaging and agricultural product turnover.

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |