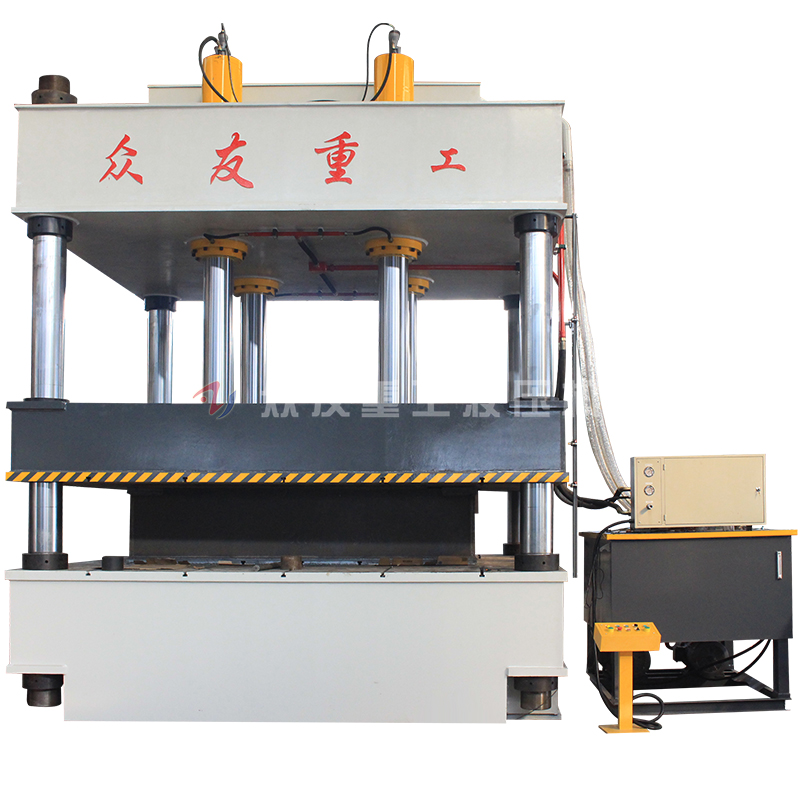

graphite crucible forming machine metallurgical refractory sagger hydraulic press 630 tons powder forming hydraulic press

The sagger forming machine is a special machine for graphite saggers developed by our company. This machine adopts a four-column model structure and is equipped with a servo system, which is more controllable and can monitor the technological process in real time.

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

Structural features

Three beams and four columns: composed of upper beam, middle beam, lower beam and four columns, forming a stable frame structure, withstanding high pressure (usually 100-1000 tons) and high temperature (up to 300-800 ℃), suitable for continuous high pressure hot pressing process.

Modular design: workbench, mold, heating system can be quickly replaced, adapt to different product requirements.

Core advantages

High precision: The four-column guide structure ensures the smooth movement of the slider, and the pressing accuracy reaches ± 0.1mm.

Efficient heating: using resistance wire, induction heating or oil temperature circulation system, the heating rate can reach 10-30 ℃/min.

Multi-function: support hot pressing, cold pressing, vacuum pressing and other modes, adapt to complex process requirements.

Powder pressing: The ceramic powder (such as alumina, silicon nitride, zirconia, etc.) is pressed into a high-density body by high pressure (200 tons nominal pressure), which is suitable for electronic components, insulating materials, wear-resistant parts, etc.

Multi-step/special-shaped pressing: support complex mold design (such as flange, sleeve, special-shaped insulator), to achieve multi-step, special-shaped structure of a molding.