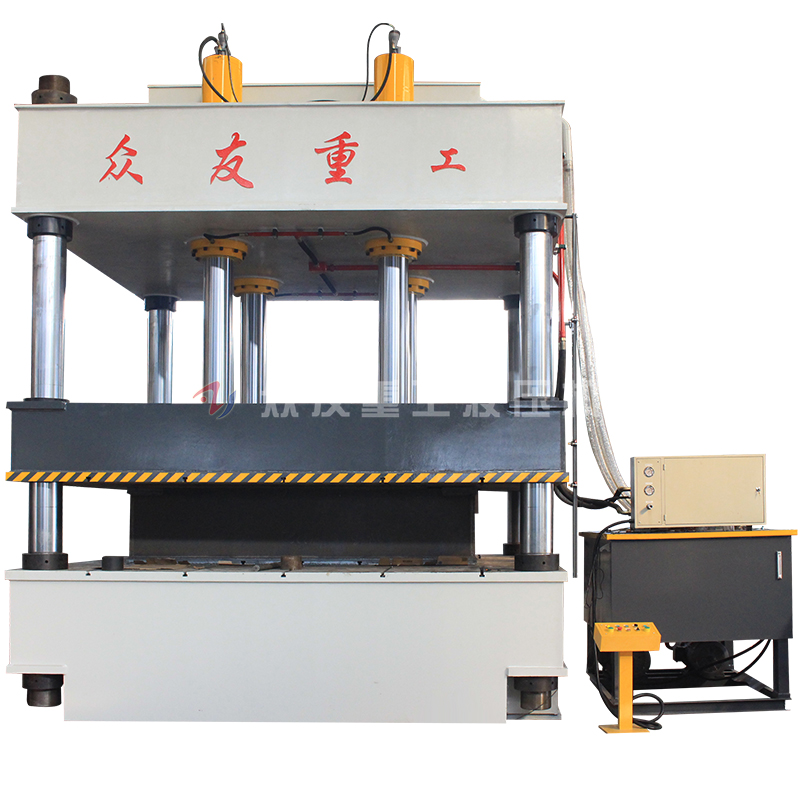

630 tons of four-column silicic acid cover plate forming hydraulic press 630T four-column silicic acid cover plate hot pressing hydraulic press

Details of the machine This machine is composed of two parts: the host and the control mechanism, which are connected by pipelines and electrical devices to form a whole. The host part includes the fuselage, the master cylinder, the limited range device, etc. Control mechanism including hydraulic

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

Calcium silicate board is a new type of inorganic building materials made of calcium materials, siliceous materials, reinforcing fibers, additives, etc. according to a certain proportion, by copying or molding, autoclaved curing and other processes. Because of its light weight, high strength, and has a good processing function and non-combustible. Moisture, sound insulation and thermal insulation effect is also very good, so it is widely used in the ship's compartment, ceiling and the construction of non load-bearing walls, as well as other places with fire protection requirements.

1.630 tons of calcium silicate boardforming hydraulic pressThe host is a four-beam and four-column structure, equipped with special powder shifting and hydraulic proportional floating molding technology, so that the molding density of the products can be effectively controlled.

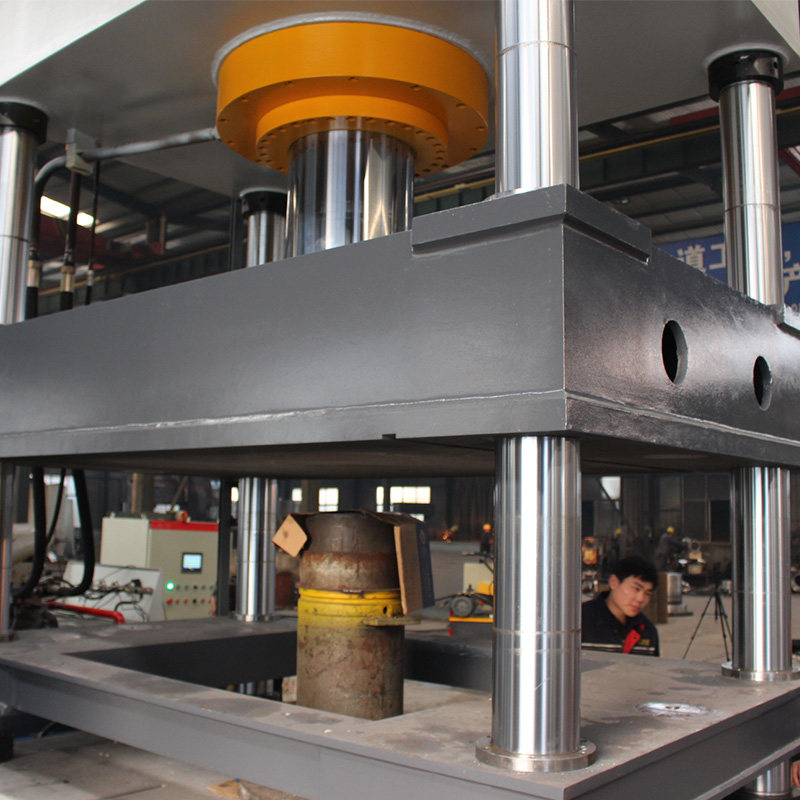

2. The mechanical stop positioning and stepless adjustment mechanism in the three positions of loading, molding and demoulding ensure the stable and adjustable geometry of the products. Step products move powder position steplessly adjustable, uniform product density.

3. The 630-ton calcium silicate board forming hydraulic press has the functions of demoulding overpressure protection and micro-return, and adopts the demoulding protection device of the upper pressure head with adjustable force and stroke, so as to improve the qualified rate of the product and avoid the damage of the mold. The unique electrical control technology can flexibly set the action program of each product step drive component on the touch screen according to the product molding requirements, without changing the internal program, which meets the requirements of the industry's complex product shape and the pressing molding requirements of multi-variety step parts, and has strong versatility.

4. The hydraulic control adopts cartridge valve integrated system, which has large flow and stable operation. It also has the function of pressure overload protection. The upper limit of the slider has a safety bolt structure, and a charging protection device is installed in front of the workbench. Independent and reliable electronic control system, with a wide range of versatility, suitable for the pressing and forming of composite materials;

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Suppression case

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Suppression case