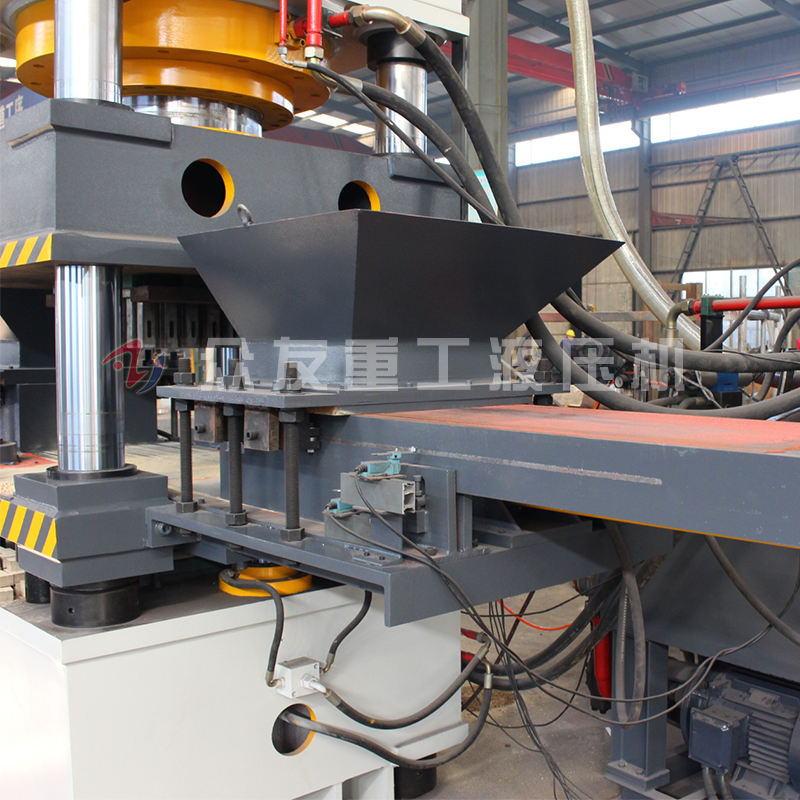

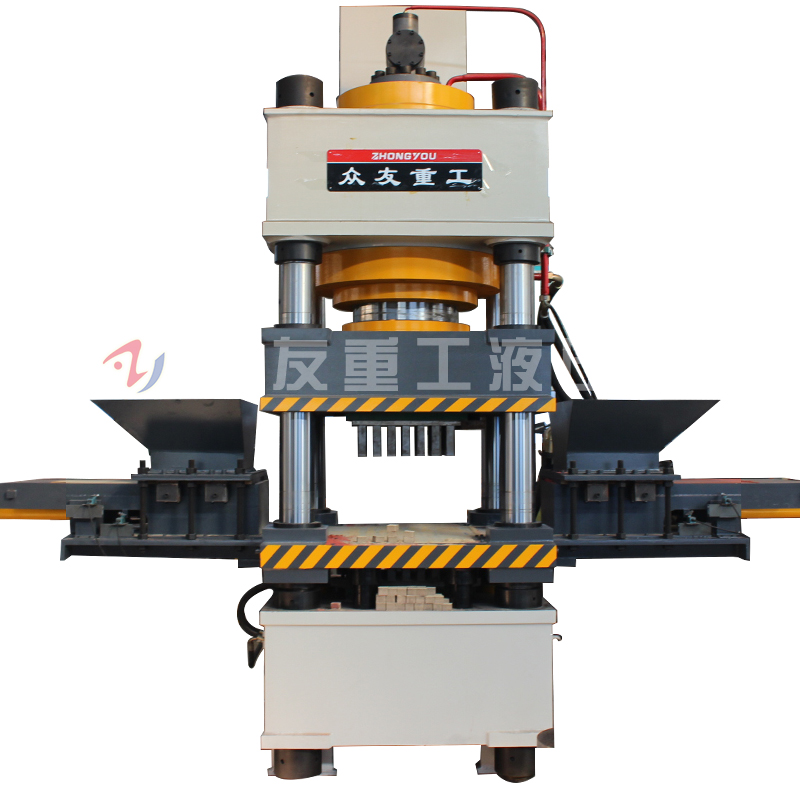

630 tons two-color bait briquetting machine 630t powder forming hydraulic press

The 630-ton automatic feeding bait pressing block hydraulic press is produced for an enterprise in Guangdong. It can press a variety of bait blocks at a time according to customer needs. It can be produced according to user product needs, with a high forming rate and greatly reduced rejection rate.

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

630 tons of automatic feeding bait briquetteforming hydraulic pressAlso known630Tpowder forming hydraulic press, using three-beam four-column structure design, Tengzhou, ShandongZhongyou Heavy IndustryMachinery Equipment Co., Ltd. is a professional manufacturer of bait briquetting machines. It can design and produce new two-color bait briquetting machines according to market demand and customer requirements. It can press various quantities of bait blocks at one time according to customer demand. The bait blocks are composed of various raw materials. According to the output and size, it is divided into 200 tons, 315 tons and 400 tons, 500 tons and 630 tons.four-column hydraulic pressAnd so on multiple models. One630 tons automatic feeding bait briquetting hydraulic pressCan press a variety of specifications of lure block, can be completed by changing the mold, do not need to buy multiple equipment. More information welcome to consult us

The equipment is to manufacture bait spices, etc. through 630 tons of fish bait blocksPowder forming hydraulic press_630T fish feed briquetting hydraulic press presses into massive or round cake-shaped products under high pressure. There are holes in the middle, and the fishing line is perforated and hung with fishing hooks. It is often used in entertainment places such as leisure and vacation fishing. Shandong Tengzhou Zhongyou Heavy Industry can customize different tonnage bait briquetting machines according to customer needs. Commonly used are 500 tons, 630 tonsThree-beam four-column hydraulic pressEquipment

Technical advantages of 630T bait block powder molding hydraulic press_630 ton two-color bait briquetting press:

1. The host is constructed of cast steel parts, which has good rigidity, strong stability, stable operation, no noise, and prolongs the service life of the machine.

2, the use of domestic PLC hydraulic transmission technology, high degree of automation, greatly reducing the labor intensity of workers, high work efficiency.

3. Using a unique pressing molding process, the molding pressure is large, the pressed products are of good quality, not easy to break, and have a beautiful appearance.

4. The hydraulic components adopt the world's hydraulic components, and the pumping station can achieve continuous normal work with low failure rate.

5. The centralized button control adopted by the electrical control cabinet is easy to learn and understand, and convenient for users to operate.

Changing the mold can produce products of different shapes, ensuring the diversified needs of products.

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Suppression case

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Suppression case