200-ton tire pressing machine Solid tire pressing machine Engineering tire hydraulic press

Tire press machine introduction Tire press machine adopts computer optimization structure design, the structure adopts the whole steel plate CO2 welding, to ensure that the body never deformation, has an independent electrical control system, reliable work, intuitive action, convenient maintenance. The tire pressing machine can preset the pressure and can press various types of tires with global standard rims

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

Tire pressIt is a kind of equipment specially used for disassembling and assembling wheels and tires with retaining rings, especially suitable for the disassembly and assembly of various solid tires

Functional features

Precise disassembly and assembly: Press the tire into the wheel hub through tooling and pressure head to ensure that the disassembly process does not damage the tire or wheel hub.

Efficient exhaust: some models (such as tread press) can remove the air between the tread and the carcass to avoid bubbles.

Safety design: equipped with manual valve control, safety light curtain and other devices to prevent accidental operation.

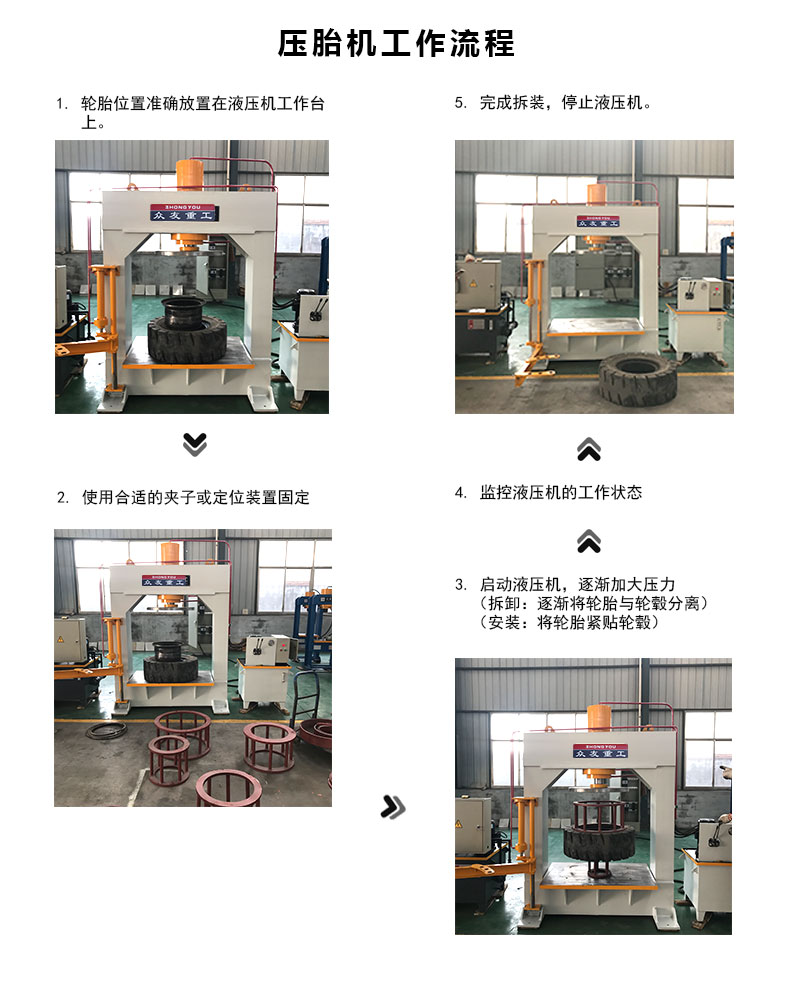

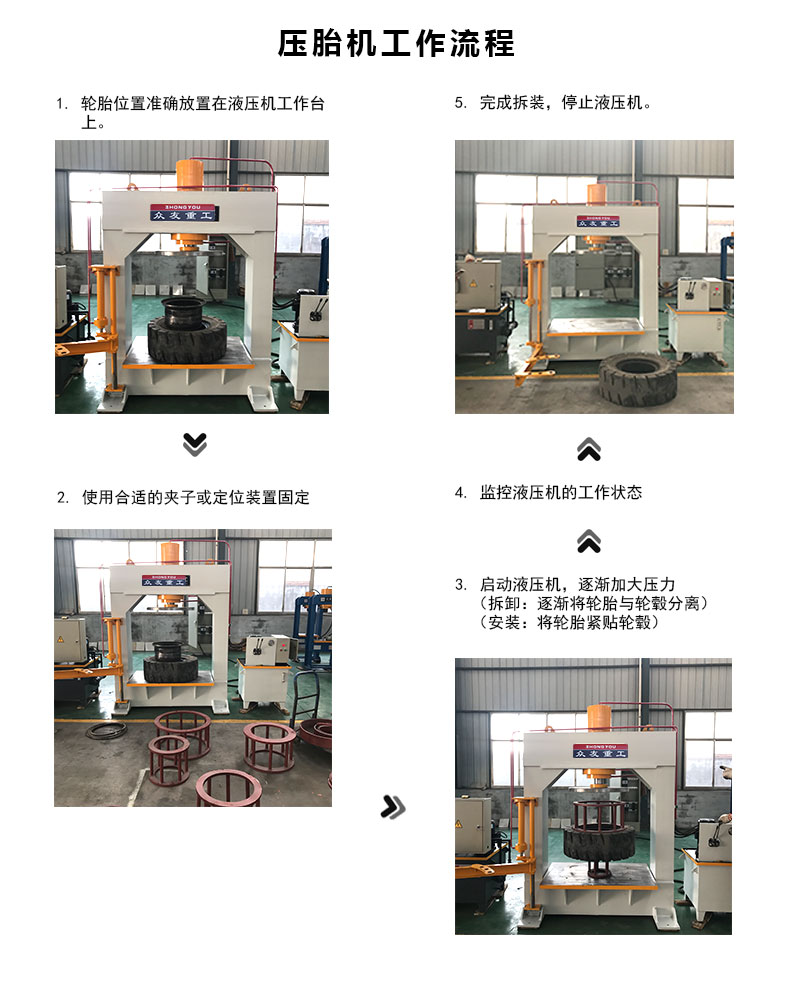

Operation steps

Select the tooling according to the tire model and place it on the workbench.

Place the hub on the tooling, and press the pressure head into the tire with the tooling.

Use the guide ring to fit the snap ring to complete the tire fixation.

Some equipment can be equipped with hydraulic lifting arm to facilitate the handling of tires.

Industrial vehicles

Forklift tires: 200-ton gantry tire pressing machine is widely used in the disassembly and assembly of forklift solid tires, with simple operation and high efficiency.

Engineering vehicle tires: electric tire press is suitable for the disassembly and assembly of large-tonnage engineering vehicle tires to meet the needs of high-intensity operations.

Special Industry

Explosion-proof places: suitable for disassembly and assembly of explosion-proof vehicle tires in petroleum, chemical, natural gas and other industries.

Clean environment: meet the electrolysis workshop, communication machine assembly workshop and other tools do not rust, wear-resistant anti-magnetic requirements.

Tire retreading

Tread pressing: evenly press the tread rubber on the carcass to eliminate air and ensure the quality of retreading.

Vulcanization treatment: cooperate with the vulcanizing tank for high temperature vulcanization to make the tread and the carcass firmly combined.

Technical parameters

| Parameter Name | Unit | 100 tons of gantry | 120 tons of gantry | 160 tons of gantry | 200 tons of gantry | Wheel Hub Model |

| Nominal force | KN | 1000 | 1200 | 1600 | 2000 | 8-15 |

| Maximum pressure of hydraulic system | Mpa | 25 | 25 | 25 | 25 | 8-15 |

| Maximum opening distance of slider | mm | 1100 | 1100 | 1200 | 1200 | 8-20 |

| Effective stroke of slider | mm | 500 | 500 | 600 | 600 | 8-24 |

| Effective area of workbench | mm | 1000*800 | 1000*800 | 1400*800 | 1400*800 | 8-25 |

Suppression case

Technical parameters

| Parameter Name | Unit | 100 tons of gantry | 120 tons of gantry | 160 tons of gantry | 200 tons of gantry | Wheel Hub Model |

| Nominal force | KN | 1000 | 1200 | 1600 | 2000 | 8-15 |

| Maximum pressure of hydraulic system | Mpa | 25 | 25 | 25 | 25 | 8-15 |

| Maximum opening distance of slider | mm | 1100 | 1100 | 1200 | 1200 | 8-20 |

| Effective stroke of slider | mm | 500 | 500 | 600 | 600 | 8-24 |

| Effective area of workbench | mm | 1000*800 | 1000*800 | 1400*800 | 1400*800 | 8-25 |

Suppression case