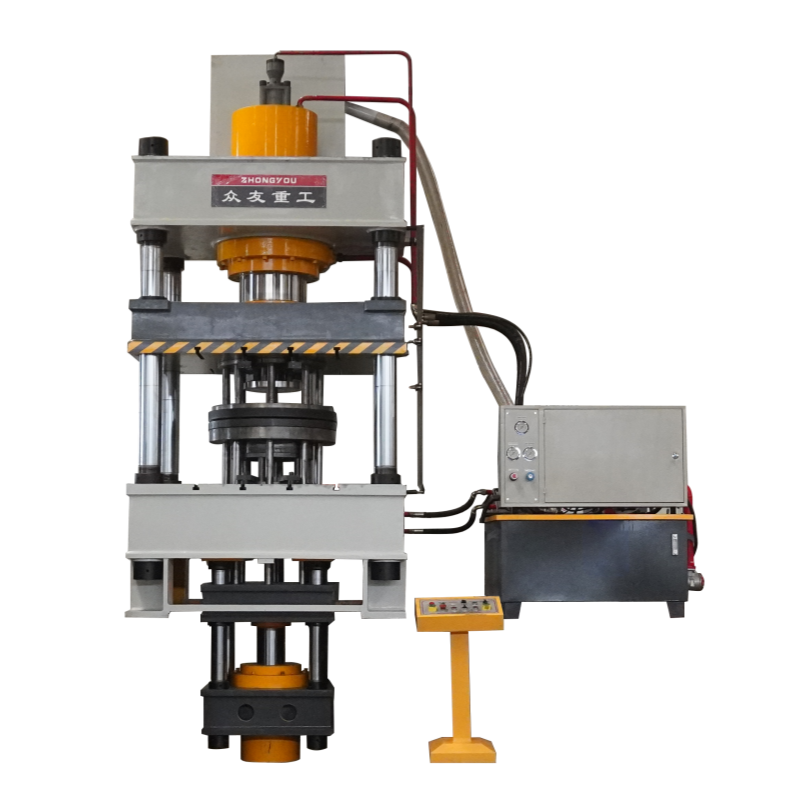

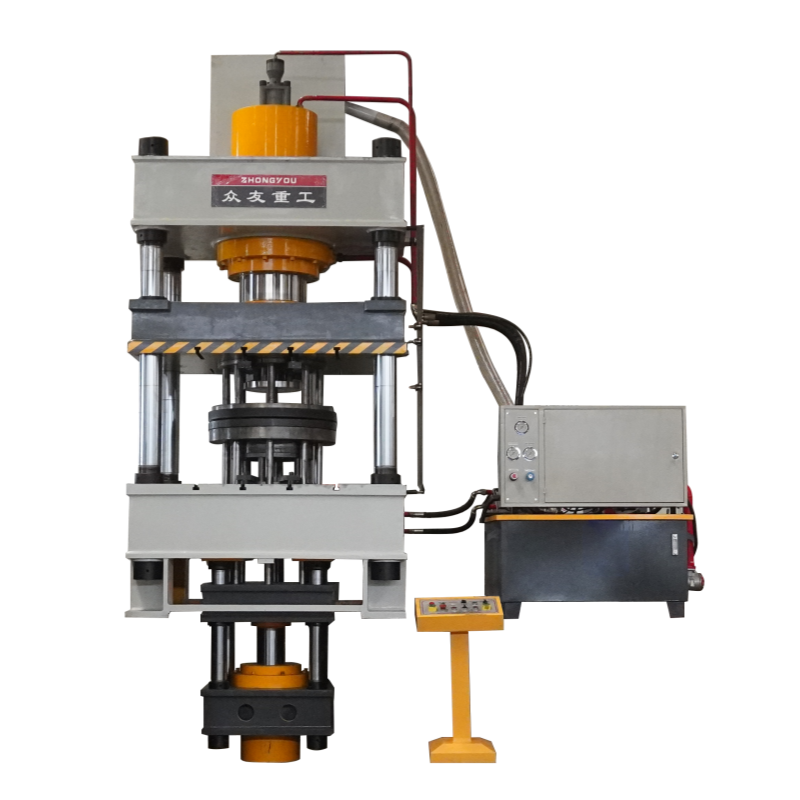

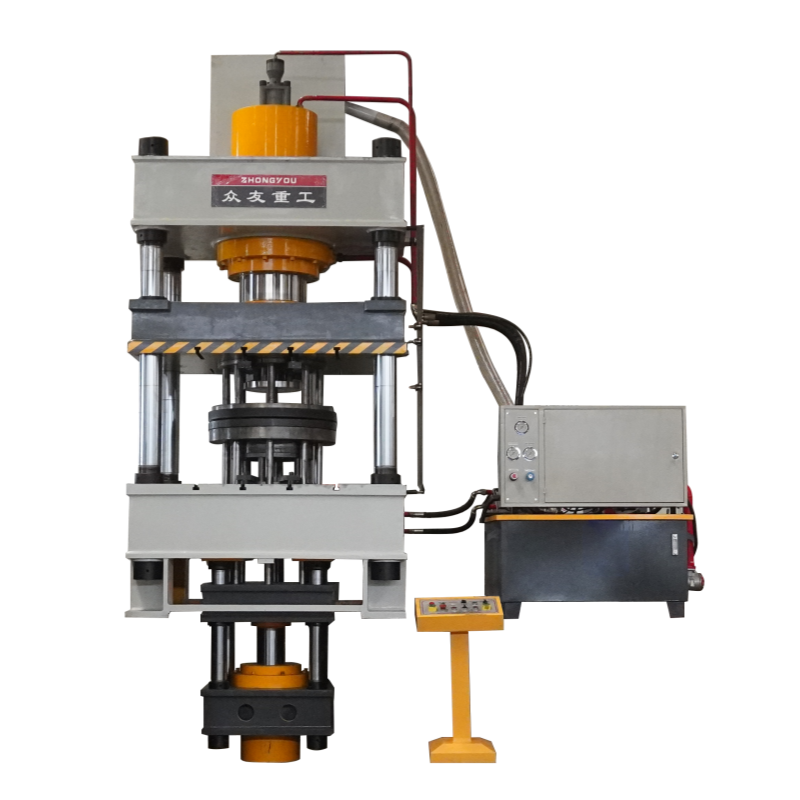

400-ton stainless steel large basin stretching machine metal stretching forming hydraulic machine

A 400-ton stretching machine customized by Shandong Zhongyou Heavy Industry for Anhui customers is used for special hydraulic equipment for forming large-size stainless steel metal basins (such as kitchen soup basins, vegetable washing basins, industrial liquid storage basins, etc.)

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

ShandongZhongyou Heavy IndustryA 400-ton stretching machine customized for Anhui customers is used for special hydraulic equipment for forming large-size stainless steel metal basins (such as kitchen soup basins, vegetable washing basins, industrial liquid storage basins, etc.).

The stainless steel metal basin stretching machine presses the hydraulic oil into the cylinder through the hydraulic pump, generating huge pressure to push the piston up and down, and then stretch the stainless steel plate. The equipment can accurately control parameters such as pressure, speed and displacement to ensure that the stainless steel sheet is evenly stressed during the stretching process to achieve the expected forming effect

Equipment features and advantages

High-precision molding: The use of advanced hydraulic systems and precise control systems can achieve high-precision pressure and displacement control to ensure the quality of molding.

High efficiency production: high degree of automation, pressing quality assurance, can significantly improve production efficiency.

The structure is stable and reliable: the fuselage is welded with all-steel CO₂, and the vibration treatment is carried out after welding to ensure that the fuselage is not deformed. The guide post, piston rod and other key components are plated with hard chrome after intermediate frequency quenching, which is not easy to rust and nose.

Safe and convenient operation: it is equipped with independent hydraulic and electrical control system, and adopts button centralized control, which can realize two molding processes of fixed range and constant pressure. At the same time, equipped with pressure display and stroke, pressure adjustment and other functions, the operation is safer and more convenient.

Customized service: can be customized according to customer needs of different tonnage and structure of the drawing machine, to meet the different specifications and sizes of stainless steel basin molding needs.

| YD27 series three beam four column hydraulic press | |||||||

| project | 100T | 200T | 315T | 400T | 500T | 630T | 800T |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 700 | 800 | 900 | 1200 | 1200 | 1200 |

| Opening height mm | 800 | 1100 | 1250 | 1500 | 1800 | 1800 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 5-10 | 5-15 | 5-10 | 5-10 | 5-10 | 8-15 | 8-15 |

| Return speed mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Erect force t | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 300 | 200 | 220 | 220 | 300 | 300 |

| YD27 series three beam four column hydraulic press | |||||||

| project | 1000T | 1250T | 1600t | 2000T | 2500T | 3000t | 4000t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 1200 | 1400 | 1400 | 1400 | 1400 | 1600 | 1600 |

| Maximum opening height mm | 1800 | 2000 | 2000 | 2000 | 2000 | 2200 | 2200 |

| Effective area of workbench | 1260*1160 | 1600*1000 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 | 1800*1800 |

| Idle descent speed mm/s | 120 | 150 | 150 | 160 | 160 | 160 | 180 |

| Pressing speed mm/s | 5-12 | 5-12 | 5-12 | 5-12 | 10 | 6-10 | 6-10 |

| Return speed mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Erect force t | 100 | 100 | 100 | 125 | 125 | 200 | 200 |

| Ejecting stroke mm | 350 | 350 | 350 | 350 | 350 | 450 | 450 |

pressing process

Suppression case

| YD27 series three beam four column hydraulic press | |||||||

| project | 100T | 200T | 315T | 400T | 500T | 630T | 800T |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 700 | 800 | 900 | 1200 | 1200 | 1200 |

| Opening height mm | 800 | 1100 | 1250 | 1500 | 1800 | 1800 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 5-10 | 5-15 | 5-10 | 5-10 | 5-10 | 8-15 | 8-15 |

| Return speed mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Erect force t | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 300 | 200 | 220 | 220 | 300 | 300 |

| YD27 series three beam four column hydraulic press | |||||||

| project | 1000T | 1250T | 1600t | 2000T | 2500T | 3000t | 4000t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 1200 | 1400 | 1400 | 1400 | 1400 | 1600 | 1600 |

| Maximum opening height mm | 1800 | 2000 | 2000 | 2000 | 2000 | 2200 | 2200 |

| Effective area of workbench | 1260*1160 | 1600*1000 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 | 1800*1800 |

| Idle descent speed mm/s | 120 | 150 | 150 | 160 | 160 | 160 | 180 |

| Pressing speed mm/s | 5-12 | 5-12 | 5-12 | 5-12 | 10 | 6-10 | 6-10 |

| Return speed mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Erect force t | 100 | 100 | 100 | 125 | 125 | 200 | 200 |

| Ejecting stroke mm | 350 | 350 | 350 | 350 | 350 | 450 | 450 |

pressing process

Suppression case