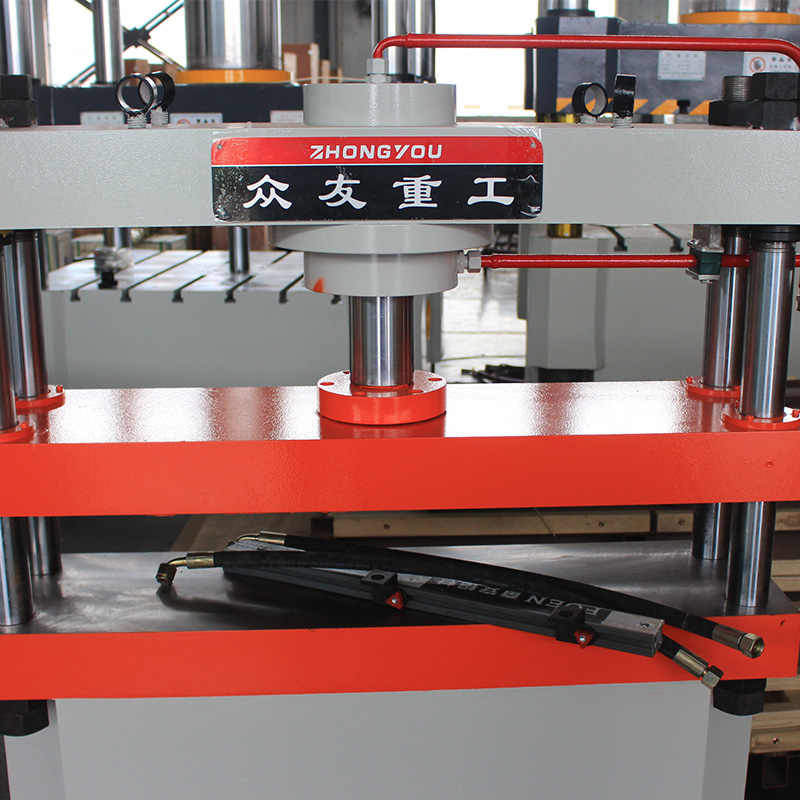

63 tons four-column small hydraulic press 63T metal forming hydraulic press kitchenware stretching hydraulic press

The 63-ton four-column hydraulic press is independently developed, produced and designed by Shandong Tengzhou Zhongyou Heavy Industry Machinery Equipment Co., Ltd. It is customized for Guangdong teaching laboratory. The structure is simple, economical and practical, the working space is spacious, the whole machine structure is simple, and the manufacturability is good.

Scan code plus WeChat

+86 13562463338

+86 13562463338

Video Show

Introduction of hydraulic press

63 tonsfour-column hydraulic pressIt's Tengzhou, ShandongZhongyou Heavy IndustryThe independent research and development, production and design of mechanical equipment co., ltd. is customized for Guangdong teaching laboratory. the equipment is composed of two parts: the main engine and the control mechanism, which are connected by pipelines and electrical devices to form a whole. The host part includes the fuselage, the master cylinder, the limited range device, etc. The control mechanism includes hydraulic pump station (power system), electrical box, mobile console, etc.The host adopts a three-beam and four-column structure, which is easy to operate and reliable, and can increase the corresponding auxiliary devices according to the requirements of the specific molding process.This small hydraulic pressThe structure is simple, economical and practical. Its distinctive features are spacious working space, simple structure of the whole machine, and good manufacturability,In addition, our company also designs and produces various tonnages.Powderforming hydraulic press、frame type hydraulic press、Metal stretching hydraulic pressWait. Can be designed and produced according to user parameters, to ensure that the large table pressure uniform. Low noise, energy saving and environmental protection, can reduce power consumption, extend the service life of the hydraulic press, and reduce production costs. For more information about the equipment, please call for advice.

1、63 ton hydraulic pressLow failure rate, high degree of automation, high work efficiency.

2. The host has a compact structure and a small area, which is convenient for movement and transportation.

3. Four groups of guiding structure, high molding pressure, high compactness of pressed products, and not easy to break.

4. The structure design of the hydraulic pump station of the hydraulic press is reasonable. The highly concentrated hydraulic control valve block and the unique oil circuit design make the hydraulic system perfect and effectively realize the continuous normal production.

5. Electrical control program realizes human-computer interaction, simple operation, convenient and quick.

6. Low failure rate, low calorific value, high working efficiency, power saving and durability.

Three-beam four-column hydraulic pressIt is suitable for the pressing process of various plastic materials, such as stamping, bending, flanging, stretching, forming, blanking, bending, etc. Can also be engaged in calibration, press, grinding wheel molding, plastic products and powder products pressing molding

1. Auto parts; body covers, brake pads, fuel tanks, chassis, axle housings, bumpers.

2. Household appliances: washing machines, rice cookers, televisions, refrigerators, air conditioners and other parts.

3. Kitchen utensils: sinks, pots and other containers., metal forming machine tools, mining machinery and equipment, metal cutting machine tools, mechanical and electrical equipment, hardware and electrical equipment and related mechanical parts; operating the enterprise related import and export business. After long-term development, our company has become one of the professional manufacturers in China's oil press industry. At present, the company has large-scale advanced equipment such as floor boring and milling machines, heavy-duty lathes, milling planers, etc.single-arm hydraulic pressDouble column hydraulic press, frame type hydraulic press,Gantry hydraulic press, three-beam four-column hydraulic press and advanced multi-functional hydraulic press and other hydraulic machinery equipment, followed by the production of various types of hydraulic press, press auto protection equipment, multi-functional full-automatic steel ring top changing machine, brake hub boring machine, shearing machine,forging pressBed, punch, bending machine, etc.

The company pays attention to the progress of science and technology, adopts advanced network platform, CAD and CAPP computer technology for auxiliary design, has a technology center suitable for its own development, and has a scientific research team of dozens of people with reasonable structure, complete specialty and rich experience, with excellent R & D ability

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Suppression case

Technical parameters

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 100T-A | 100T-B | 160T | 200T-A | 200T-B | 315T-A | 315T-B |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 500 | 600 | 600 | 700 | 600 | 800 | 600 |

| Opening height mm | 800 | 900 | 900 | 1200 | 900 | 1250 | 1000 |

| Effective area of workbench | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 | 800*800 |

| Idle descent speed mm/s | 100 | 100 | 100 | 100 | 100 | 120 | 120 |

| Pressing speed mm/s | 7-15 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return speed mm/s | 90 | 90 | 90 | 90 | 90 | 100 | 90 |

| Motor power KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 | 15 |

| Jacking force KN | 200 | 200 | 400 | 400 | 400 | 630 | 630 |

| Ejecting stroke mm | 200 | 200 | 200 | 200 | 200 | 300 | 300 |

| YQ32 series three-beam four-column hydraulic press | |||||||

| project | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid pressure Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective stroke of slider mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum opening height mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Effective area of workbench | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle descent speed mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing speed mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Return speed mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor power KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Jacking force KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejecting stroke mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

pressing process

Suppression case